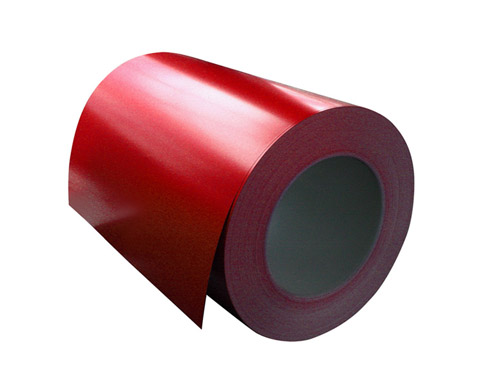

Prepainted Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DX51D; EN10169; ZN 100 /140 /180 gr/sqm

TOP COAT: 5+20 MICRON MODIFIED POLYESTER

BACK COAT: 7-12 MICRON" PAPYURUS WHITE" / RAL 9002

SUITABLE FOR P.U FOAMING

THICK

WIDTH

TOP COLOUR

Top Paint Type

0.35

1000

WHITE RAL 9003

SMP

0.4

1000

BLACK RAL9005

SMP

0.4

1220

WHITE RAL 9016

SMP

0.45

1000

WHITE RAL 9016

SMP

0.45

1220

CREAM RAL 1015

SMP

0.45

1220

WHITE RAL 9016

SMP

0.48

1135

WHITE RAL 9016

SMP

0.47

1220

CREAM RAL 1015

SMP

0.5

1220

GREEN RAL 6024

SMP

0.5

1220

WHITE RAL 9016

SMP

0.52

1220

DONN WHITE RAL 9003

SMP

0.6

1220

WHITE RAL 9016

SMP

0.72

1220

DONN WHITE RAL 9003

SMP

0.75

1220

WHITE RAL 9016

SMP

TOTAL

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to efficiently store and transport large quantities of steel in a compact and secure manner.

- Q: Is condensation on steel caused from water being pulled out or is the condensation formed from the air around the steel object?

- Steel contains no water; any water that you see is condensed out of the air.

- Q: Steel roofing info. Pros and cons on steel roofing?

- Steel roofing Pro...life of product is much longer then Asphalt shingles....Looks great...multi colors.......Just love the stuff... Cons....More costly then singles at first but since it last longer it is really a better buy.......

- Q: what are the properties that can strengthen the steel to withstand earhquake?

- Well, its not necessary how strong steel is but how buildings are designed that withstands earthquakes. Steel as a property has to elastic qualities and when earthquakes are initiated but moving of the plates, the building has to absorbed the effects of the earth movements while remain standing. This does not necessary mean that the building will be usable afterward but it has to remain standing. Now, how does a building remain standing? All building have within its design a VLLRS (vertical lateral load resisting system). This system is basically designed to resist earthquake loads as well as wind loads. In steel buildings, this system is usual made of OMF (Ordinary moment frames) or braced frames. These frames act to absorb the lateral loads and transmit them into the foundation below. If the structure was concrete, there would still be moment frames made of concrete and steel but you know that concrete has a elasticity that is less than steel. ALthough there elasticity is less, they are stiffer and concrete structure tend to resist more lateral load because of it. In concrete, we can create shear walls which are basically walls that are thick and wide to resist lateral load from earthquake and wind. Masonry has even a lesser strength than steel or concrete and wood even less than above. What makes them usful is how they are used to resist earthquake loads or lateral loads from earthquake and wind. So, to answer your question, its not nessary how strong the steel is but how the material is used to resist earthquake is what is important.

- Q: What are the challenges faced during steel coil processing?

- Some of the challenges faced during steel coil processing include ensuring proper alignment and feeding of the coils into the machinery, handling the heavy weight and size of the coils, managing the high temperatures involved in processing, preventing surface defects or damage to the steel, maintaining consistent quality throughout the process, and minimizing material waste and scrap.

- Q: I have hundreds of pounds of scrap steel... who purchases this steel and what is the price per pound etc. of this? Does someone pick it up or do I bring it somewhere?

- It okorder /

- Q: How are steel coils used in the production of automotive body panels?

- Steel coils are used in the production of automotive body panels by being processed and formed into the desired shape and size. The coils are typically unwound and fed through a series of machines that stamp, press, or roll the steel into the required panel shape. This process allows for efficient mass production of body panels, ensuring strength, durability, and precision in the final product.

- Q: How are steel coils used in the production of steel plates?

- Steel coils are used in the production of steel plates by being fed into a rolling mill where they are gradually flattened and shaped under high pressure. This process, known as hot rolling, transforms the steel coils into thin and flat plates that can be further processed and used in various industries such as construction, automotive, and manufacturing.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- Rust is the process of steel oxidizing when in contact with oxygen, this reaction can be much fast if certain components are present, such as wet air or water. However, if the paint completely isolates the steel from the environment, the encompassed steel will never rust as long as paint shields it. Aluminum corrodes but it does not rust. Rust refers only to iron and steel corrosion. Aluminum is actually very prone to corrosion. However, aluminum corrosion is aluminum oxide, a very hard material that actually protects the aluminum from further corrosion. Aluminum oxide corrosion also looks a lot more like aluminum, so it isn't as easy to notice as rusted iron.

- Q: How are steel coils inspected for chemical composition?

- The chemical composition of steel coils is examined using spectroscopy, a process that involves the utilization of a spectrometer. This instrument analyzes the light emitted or absorbed by a sample to determine its chemical makeup. Normally, a small portion of the coil is taken and prepared for analysis in the case of steel coils. This portion is then placed in the spectrometer, where a beam of light is emitted onto it. The light interacts with the atoms and molecules in the sample, causing specific wavelengths of light to be emitted or absorbed. The spectrometer measures the intensity of the emitted or absorbed light at different wavelengths and generates a spectrum, which is essentially a distinct fingerprint for the sample. This spectrum is then compared to a database of known spectra for various elements and compounds to ascertain the chemical composition of the steel. Through spectroscopic analysis, the presence and concentration of different elements like carbon, manganese, phosphorus, sulfur, and other trace elements in the steel can be identified. These elements have a significant impact on the steel's properties, strength, and suitability for different applications. Ensuring that the steel complies with the required specifications and standards, inspection for chemical composition is crucial in the steel industry. Any deviation from the desired chemical composition can potentially compromise the steel's performance and result in structural failures or other defects. In conclusion, spectroscopy offers a highly precise and dependable method for examining the chemical composition of steel coils. This aids in maintaining the quality and integrity of the steel products.

Send your message to us

Prepainted Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords