Prepainted Galvanized Steel

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

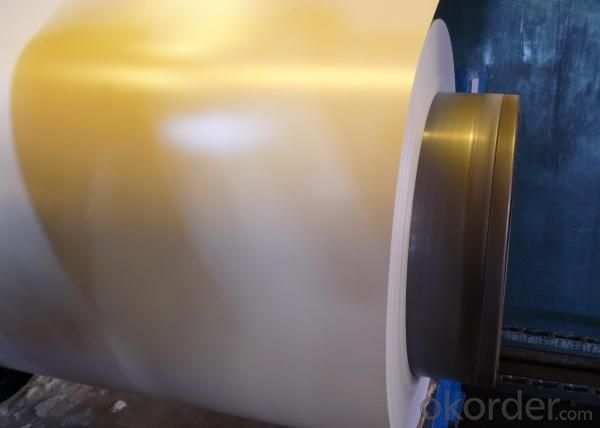

Prepainted Galvanized Steel

With galvanized steel as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Brand Name: HBSTEEL

Specifications OfPrepainted Galvanized Steel

|

Thickness 0.20-1.2mm (BMT) Width 600-1250mm |

|

Zinc Coating 100-275g/m2 |

|

Color According to RAL color fan or as per request |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 3-6MT |

|

Quality Commercial and structural quality |

|

Paint Polyester paint for topside, epoxy for reverse |

|

Standard JIS G 3312, ASTM A755M, EN 10169 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD,S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

|

C |

Si |

Mn |

P |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Reverse Impact |

9J |

|

T-bending |

≥2T |

|

Pencil Hardness |

≥2H |

|

Duration Of Salt Spray Test |

500 H |

|

Bending At 180 Degree |

No crack, purling and fraction |

Applications OfPrepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

Packaging & Delivery Of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Production Flow Of Prepainted Galvanized Steel

Production flow of hot sell prepainted galvanized steel include dual uncoiler,stitcher, bridles, entry accumulater, degreasing & chemical section, prime coater, prime oven, prime water quench, finish coating, finish back coater, finish oven, finish water quench, exit accumulater and recoiler.

- Q: How are steel products used in the construction of museums and cultural centers?

- Steel products are commonly used in the construction of museums and cultural centers for their strength and durability. They are used in various structural components such as beams, columns, and trusses, providing stability and support for the building. Steel is also used for roofing, cladding, and façade systems, offering both aesthetic appeal and weather protection. Additionally, steel is often used in the construction of exhibit displays and installations, providing a flexible and customizable solution. Overall, steel products play a crucial role in creating safe, long-lasting, and visually appealing spaces for preserving and showcasing cultural artifacts and experiences.

- Q: What are the uses of steel wire mesh in agriculture?

- Steel wire mesh has several uses in agriculture. It is commonly used as fencing to protect crops and livestock from external threats such as animals or trespassers. Additionally, steel wire mesh is used as a trellis system for supporting climbing plants like tomatoes, beans, or grapes, ensuring their proper growth and maximizing yield. It can also be utilized as a protective covering for fruit trees or vegetable beds, preventing damage caused by birds or insects. Overall, steel wire mesh is a versatile tool that aids in securing and enhancing agricultural practices.

- Q: How do steel products contribute to the automotive aftermarket industry?

- Steel products play a crucial role in the automotive aftermarket industry by providing various components and parts that are essential for vehicle maintenance and repair. From body panels and chassis frames to engine parts and suspension components, steel is widely used due to its strength, durability, and cost-effectiveness. Steel products ensure the safety and reliability of vehicles, contributing to the overall growth and success of the automotive aftermarket industry.

- Q: How do steel products contribute to the electrical and power transmission sector?

- Steel products play a crucial role in the electrical and power transmission sector by providing the necessary infrastructure to support and transmit electricity efficiently. Steel is used in the construction of transmission towers, poles, and substations, which form the backbone of power transmission networks. These products provide the necessary strength and durability to withstand extreme weather conditions and support high-voltage power lines. Additionally, steel is also used in the manufacturing of electrical transformers, generators, and turbines, which are essential components of power generation and distribution systems. Overall, steel products contribute significantly to the reliability and effectiveness of the electrical and power transmission sector.

- Q: How is steel used in the manufacturing of consumer goods?

- Steel is commonly used in the manufacturing of consumer goods due to its strength, durability, and versatility. It is used to create various components and structures in products such as appliances, automobiles, furniture, tools, and electronics. Steel is essential for providing stability and support, ensuring the longevity and safety of consumer goods.

- Q: What are the factors to consider when estimating the lifespan of steel structures?

- When estimating the lifespan of steel structures, several factors need to be considered. These factors include the quality of the steel used, the design and construction techniques employed, environmental conditions, maintenance practices, and the level of stress and load the structure will be subjected to. Additionally, factors such as corrosion, structural fatigue, and potential for damage due to natural disasters or accidents should also be taken into account. Proper consideration of these factors can help provide a more accurate estimation of the lifespan of steel structures.

- Q: How are steel products used in the manufacturing of electrical equipment?

- Steel products are used in the manufacturing of electrical equipment in various ways. For instance, steel sheets may be utilized for constructing the outer casings and frames of appliances and machinery. Steel wires are often employed to create the conductive elements within electrical cables. Additionally, steel can be used in the production of transformers, generators, and motors due to its magnetic properties. Overall, steel plays a crucial role in ensuring the durability, stability, and functionality of electrical equipment.

- Q: How do steel products contribute to the agriculture and farming sector?

- Steel products contribute to the agriculture and farming sector in several ways. Firstly, steel is used in the construction of farm buildings and infrastructure such as barns, silos, and storage facilities, providing durable and reliable structures for storing crops and livestock. Additionally, steel is used in the manufacturing of agricultural machinery and equipment, including tractors, plows, harvesters, and irrigation systems, which enhance productivity and efficiency in farming operations. Furthermore, steel is utilized in the fabrication of fencing and enclosures, ensuring the security and safety of livestock and crops. Overall, steel products play a crucial role in supporting and advancing the agricultural industry by providing essential infrastructure, equipment, and machinery.

- Q: What are the uses of steel wire mesh in filtration?

- Steel wire mesh is commonly used in filtration due to its durability and ability to withstand high pressure and temperature conditions. It is used to separate solids from liquids or gases in various industries such as oil and gas, water treatment, food processing, and pharmaceuticals. The mesh provides a strong and reliable barrier, allowing for efficient filtration and removal of impurities, particles, or contaminants. Additionally, steel wire mesh can be easily cleaned and maintained, making it a cost-effective and practical choice for filtration applications.

- Q: What are the different types of steel rails and their applications?

- There are several different types of steel rails, each with their own unique properties and applications. Some common types include: 1. Light rails: These are used primarily in light-duty applications such as tramways, light rail transit systems, and small industrial tracks. 2. Heavy rails: These are designed for heavy-duty applications, such as mainline railways and heavy industrial tracks. They are built to withstand high loads and provide stability. 3. Crane rails: These rails are specifically designed to handle the heavy loads of cranes and other material handling equipment. They are commonly used in ports, construction sites, and industrial facilities. 4. Guard rails: These rails are installed alongside railway tracks to prevent derailment and provide safety. They are typically made of a durable steel alloy and are designed to absorb impact in case of accidents. 5. Switch and crossing rails: These rails are used at junctions and crossings, enabling trains to change tracks. They are built with specific profiles and dimensions to ensure smooth transitions and minimize wear and tear. 6. Grooved rails: These rails have grooves or flanges on the top surface, allowing them to be used for tramways or other vehicles that require guidance. The choice of steel rail depends on various factors such as the intended application, load requirements, speed, and environmental conditions. The selection of the appropriate type of steel rail is crucial to ensure safe and efficient transportation.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | Asia |

| Company Certifications | ISO9001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 50 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Over 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Average |

Send your message to us

Prepainted Galvanized Steel

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords