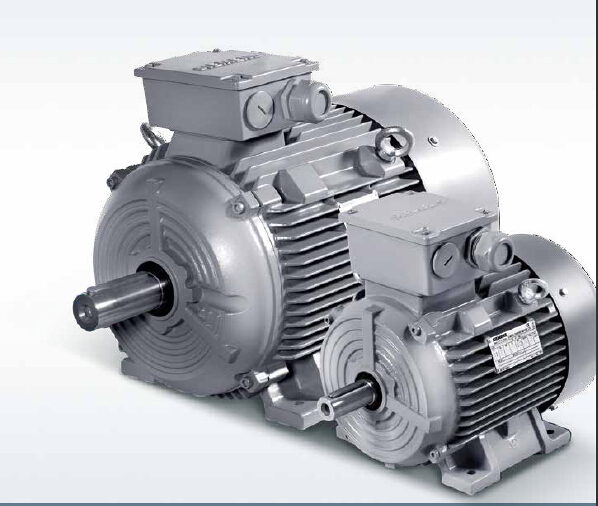

Siemens 1PQ Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: I want to control the speed of a small electric motor. I'm making a small hobby project, what parts would I need to do this, besides the motor? Also should I use a brushless, or regular motor?

- It depends. Is it a DC or AC motor? You can control a DC motor by varying the voltage applied to it. AC motors need a circuit with Triac's in it to vary the time when the AC is applied to the motor. There are electronic kits on the internet that do this for you. To control a brushless motor you need to use pulses to vary the speed. Varying the voltage level won't work. You control the speed by varying the time the voltage is applied to it.

- Q: I have a 1.5hp 220v 3 phase motor driven band saw. I need to run it on a 220v single phase system. The original single phase converter consisted of a 550uF capacitor supplying the third phase winding with the contacts of an NC relay in series with the capacitor. The coil of the relay is from the supply through a resistor to the third phase winding and dropped out when the motor came up to speed. A second 40uF capacitor is from the supply to the third phase winding and is the only capacitor that remains active when the relay opens up (motor is up to speed). I'm looking for a simpler and more reliable solution, as the present circuit is temper mental and old. Replacing the motor is a last resort. Is there a simpler capacitor type converter that can be designed? The saw is only operated intermittently for 10-15 minutes on time, 30-60 minutes off for an 8 +hour period, for a few days a month. It is used for a meat cutting band saw. Any sources, help or information would be greatly appreciated. Thank you.

- Capacitor type converters do tend to be temperamental, but the circuit you have seems to be about as simple as they come. Rotary phase converters are generally considered much better, but are also much more expensive. Another option that may be practical due to the lowering cost of semiconductors, is a is a VFD inverter drive, while the name includes variable frequency you can just as well use it at a fixed speed. Just a couple weeks ago I installed 3 conveyors with singe phase to three phase VDF inverters (albeit wit smaller motor than yours) and they work flawlessly.

- Q: How are normally AC motors reversed?

- Look at the name-- ALTERNATING current. It means that it flows in both directions. If you have an AC motor you could hook positive or negative to either side and it would work. It will spin one direction depending on how the coils are wound Direct current on the other hand has a positive and negative side. If you hook up positive and negative to a certain side it will spin what we'll call the normal direction. If you reversed the positive and negative the motor would spin opposite of the normal direction. AC can be turned into DC by the use of a diode, or something called a bridge rectifier. Put simply, it limits the flow of the current so that it turns the alternating current which is going both ways, into direct current (DC) which only goes one way.

- Q: And what fuses would I need?

- It shows that info on the motor nameplate...I think you need to add a factor to the FLA for the fuse size...

- Q: Can the voltage regulating module be used as AC motor speed regulation?

- Want to control motor speed, only changing voltage frequency on the stator can (with more of a V/F control, change the frequency corresponding to the change of voltage amplitude), change the voltage regulator will not only change the frequency, voltage, it will only change the motor torque (the size of the voltage will not change, otherwise it will cause the stator coil current is too large; for example, if you burn the motor) with voltage regulator voltage applied to the motor will change the speed two times, will have little change but far less than the two times. When using the voltage regulator experiment, do pay attention to the rated voltage of the motor, otherwise it may cause permanent damage to the motor!

- Q: When we replace dc drive with ac drive(ac motor having same capacity as dc motor) than there is alot of saving of power why? In dc drive only rectification take place where as in ac drive rectification and then inversion take place.

- I am not sure this is always true. A DC motor can be just as efficient as an AC motor. However a 3 phase induction motor as used with AC drives is likely to be a lot smaller and less costly than an equivalent DC motor. In larger DC motors it is likely they will have a field energised by DC, which is up to 10% of the motor power, and the electro-mechanical commutator is probably less efficient than electronic commutation. The speed control system used with a DC motor field may or may not be less efficient too. So the AC motor is smaller, cheaper, has less maintenance (no commutator) and does not need a field with wasted DC power. If it has a permanent magnet field, and electronic commutation/speed control, it should be just as efficient, but the distinction is becoming smaller.

- Q: What should be the resistances of 6 combinations of 3 wires of a 3 - phase AC motor connected in star configuration ?What should be the resistances of 6 combinations of 3 wires of a 3 - phase AC motor connected in delta configuration ?thanks in advance

- Whatever combination you use, typically the star is 1/3 the resistance of the delta. hth.

- Q: No sound no spark or smoke. Does it need a start capacitor I wonder now?

- You wired it wrong.

- Q: What is the neutral point of an alternating current motor? How to determine whether the neutral point leads to?

- The AC motor only meets the three-phase fire line, the three-phase is balanced, the neutral point does not connect the zero line, also does not have the ground.

- Q: what are windings on electric motor for a ac unit?

- Without getting to technical the copper wire wound in the motor case.

Send your message to us

Siemens 1PQ Series AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords