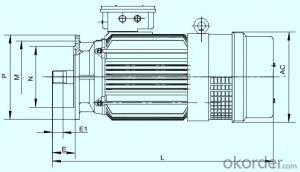

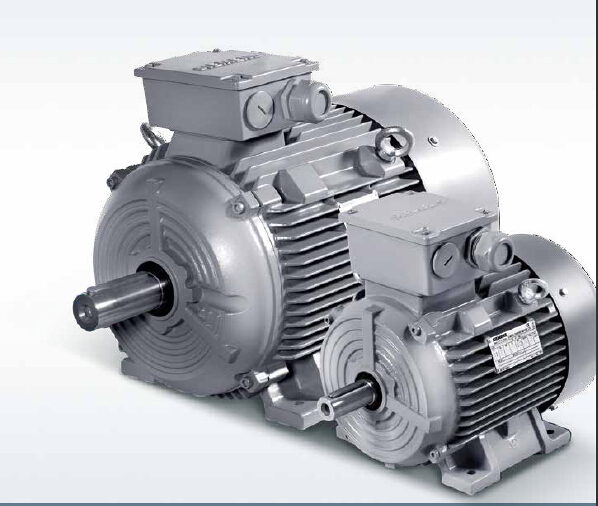

Siemens ILG Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: How do I change the speed of the motor?

- Three phase asynchronous motor speed formula is: n=60f/p (1-s) 1, do not change the synchronous speed control method. Winding motor speed control, chopper speed regulation, cascade speed regulation, and application of electromagnetic slip clutch, hydraulic coupling, oil film clutch and so on. 2. Change the speed regulation method of synchronous speed. Change the stator pole count of multi speed motor, change the stator voltage and frequency variable frequency speed regulation, there can be no commutation motor speed regulation, etc..

- Q: we want to drive generator by ac motor which is electrically connected to the same generator

- Its against the low of thermodynamics.Its Possible only with a machine whos input and out put power are equal.Every machine has losses so its not possible.

- Q: Difference between energy consumption braking of DC motor and AC motor

- Energy consumption braking is a form of braking.It is divided into DC motor energy consumption braking and AC motor energy consumption braking.

- Q: i am working with a group to build a miniature car usinga chemical reaction and need a turbine to generate electricity. Is it possible to have a small turbine and a small ac motor generate enough electricity to power a typical toy car motor. if so, what kind and how expensive are they.

- If you turn a motor in reverse it should be able to generate electricity. The problem is to find a motor that will produce the amount of electricity you need and make a turbine with sufficient power to drive the motor in reverse.

- Q: Why is the rotor of an AC motor neither magnetic nor can it rotate?

- The DC motor and AC synchronous motor works as follows: the stator or rotor produces a rotating magnetic field, while the secondary winding forms polarity. Since the two poles of the stator and rotor are attracted or repelled by each other, the rotation is generated.

- Q: how can find an electrical ac motor with outer diameter of approx. 100 mm and with minimum of 500 watt. power?

- What is the purpose? where you are going to use ?Is it continuouse rating Intermittent ratings.If it intermittent rating go for a smal size drilling machine with double speed or use a suitable speed controller use it for your pupose .These all high speed ,high torque ac motor it will not run continuously .It may be available in 120 volts /220 volta Ac even in 12v ,18,24v dc. If you need low torque use a table fan motor but wattage will be less.Best of luck.

- Q: I have a 98 BMW 7 series. The AC Blower needs to be replaced. Does the mechanic have to remove the dashboard to install a new one? Or can the replacement motor be installed through the front engine bay?

- Mitchell OnDemand tells me: Disconnect negative battery cable. Remove upper instrument panel cover. Unclip ventilation duct. Unclip and remove blower motor cover. Remove blower motor screws, disconnect electrical connectors. But, it also says the labor time is 7.8 hours, so this will NOT be a fun job. Sorry bud.

- Q: The engine would be for a boat so another question i have is does anyone have any idea how to calculate or figure how many kw it would take to run a dc motor like that obviously it would not be running at 715 hp the whole time because that is only needed for acceleration. Thank you!!!!!!!

- this must be a big boat. 715 HP converts to 533 kW by my calculator. Usually an electric motor can be smaller than an equivalent gasoline engine as it has a wider torque range. and now you see why electric cars are so difficult to make. If you used a 100 kW motor, 150HP, you would need hundreds of pounds of batteries to run it for an hour. 1 large battery has 1kw-hr of power. 100 of these would give you 100kW-hrs, enough to supply a 100kW motor for 1 hours. At a weight of maybe 2000 pounds.

- Q: What is my problem? Do I have a load that is too large on the motor.Here are the specs:AC 3-PhaseContinuous DutyConstant ToquePower Output: 5 HPBase_RPM: 1750Service Factor: 1.15Power Factor: .75Namplate Current: 14.2 AmpsNameplate Voltage: 230 VWhat I'm doing is increasing the speed of the motor with a VFD. The motor will turn the rotor up to 300 RPM (Well below its base RPM) before it exceeds its nameplate current, which causes the motor to be tripped. Is the motor drawing current above it's rated value to produce more torque to spin the flywheel? The motor can produce 15 ft*lb of constant torque at any speed up to its base rpm, and it is drawing 15.5 Amps at 50 Volts before it trips.

- I assume that when you say that the motor is tripped, you are referring to the electronic overcurrent trip function of the VFD. You can probably increase the trip point to 150% of rated output current unless the VFD is rated only for use with centrifugal pump and fan loads. In that case, it is not expected to be capable of providing rated motor torque below full speed. You need to read and understand the VFD manual. There may be several adjustments and/or a tuning procedure that needs to be performed. It is also possible that the VFD is defective, the motor is defective, or there is a fault in the wiring between the VFD and motor. What is the brand and model of the VFD?

- Q: whats the difference between an ac motor and an ac generator,especially in its architecture, if there r any?

- AC Motor converting Electrical Energy in to Mechanical Energy. But Generator Convert Mechanical Energy in Electrical Energy.

Send your message to us

Siemens ILG Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords