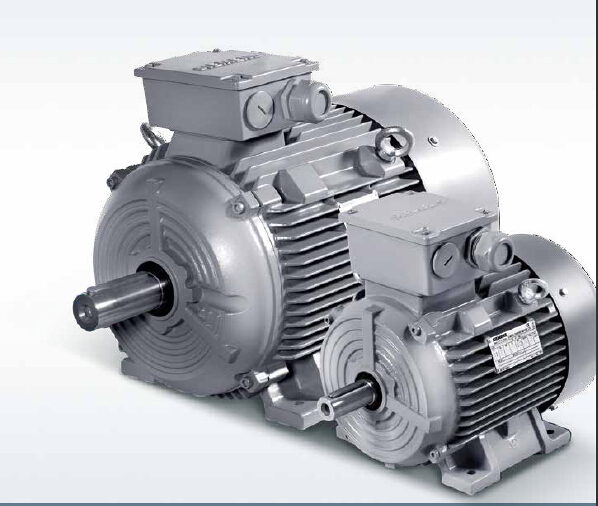

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Hairdryers are being advertised as having a AC motor or DC motor which on is best?

- It's irrelevant which motor is in it for performance. When you buy a blow dryer you should be looking for the wattage, fan output (CFM), and different speeds of the unit. If that doesn't separate one from the other, then start looking at features like cool shot, accessories. If it has an AC motor there are less electronic parts inside since no conversion is needed to power the DC motor with wall voltage.

- Q: Everything is wired correctly, can hear the relay kick on when power is on but motor will not start

- Possibly one of the coils in the motor has burned out... the wire in it will not conduct electrivity

- Q: Is it possible to have an AC current applied to a DC motor ? How about an AC motor with DC current? how is this done?

- AC voltage to DC motor. the motor will just vibrate back and forth and not rotate. It may burn out if the voltage is too high. DC voltage to AC motor, the motor will move to one phase and then draw too much current and get hot or burn out. There is a type of motor called a universal motor that can run on AC or DC. It is like a DC motor, but the field winding is switched by the commutator just like the main winding.

- Q: The difference between induction motor and induction motor

- . a three-phase induction motor is an induction motor, the induction current definition: formed by the rotating magnetic field of stator winding and rotor winding of the magnetic field from the interaction of electromagnetic torque of AC motor drive rotor rotation.

- Q: if a 3 phase motor is rated at 100 amps how many amps is that per phase?

- I agree with C anderson answer.

- Q: I understand that a brush-less DC motor must have a controller which generates AC current to drive the unit. My question is; if i bypass the controller and connect the motor directly to a bridge rectifier, will I generate power at a reasonable efficiency.If I used a 24v brush-less DC motor, would I approximately produce power of 24v?Thanks for technical expertise!

- There are 2 types of brushless motors. 1 is actually an AC motor, 3- phase,that is driven from an inverter from DC to AC. It is common in such as electric powered models, and varying the AC frequency is used to control speed. Such a motor might be used as an alternator to produce AC electricity. Then there is the brushless DC electronically commutated type motor, common in such as computer cooling fans. They cannot be used as a generator.

- Q: its wired to go cw but either way you wire it ,the motor change direction each time it stops

- your need your capacitor in your fan check !

- Q: I have 2 dc motors running off a 12 volt battery charger. It works but the motors run very slow. What can I do to make them run faster. Can I use a power inverter to convert 110v, ac into 24v, dc?

- first check is the current supply on by touching the main wire

- Q: What should be the resistances of 6 combinations of 3 wires of a 3 - phase AC motor connected in star configuration ?What should be the resistances of 6 combinations of 3 wires of a 3 - phase AC motor connected in delta configuration ?thanks in advance

- Whatever combination you use, typically the star is 1/3 the resistance of the delta. hth.

- Q: No sound no spark or smoke. Does it need a start capacitor I wonder now?

- You wired it wrong.

Send your message to us

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords