Vulcanized/Sulfuretted EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.0mm /1.2mm/1.5mm EPDM rubber roofing waterproof membrane

1. Product Description

EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material. KEQIANG EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is designed for waterproofing of exposed and non-exposed applications. KEQIANG EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

2. Features

1 Excellent physical and mechanical performance

2 High tearing resistance

3 Good deformation adaptability

4 High puncture resistance

5 High aging resistance

6 High UV resistance

3. Application

l Roofs, Basement, Toilet

l Industrial and civil building waterproofing

l Geosynthetic liner for swimming pool, channels, irrigation system

l Especially suit for projects with high requirements in durability, anti-corrosion and deformation

4. Specification

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

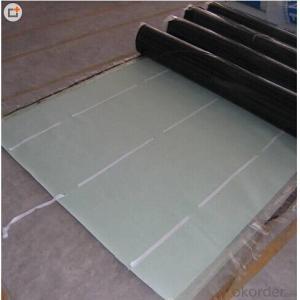

4. Product Show:

- Q: Are waterproofing membranes resistant to jet fuel?

- Waterproofing membranes are typically designed to resist the penetration of water and other liquids. However, jet fuel is a highly volatile and corrosive substance that can pose a significant challenge to the effectiveness of waterproofing membranes. While some waterproofing membranes may provide a certain level of resistance to jet fuel, it is generally recommended to implement additional protective measures when dealing with such hazardous materials. To ensure the maximum resistance against jet fuel, it is advisable to use specialized membranes that are explicitly designed to withstand the corrosive effects of this substance. These specialized membranes are typically made from materials such as polyurethane or epoxy, which have proven to be more resistant to jet fuel compared to standard waterproofing materials. Moreover, it is important to consider the specific application and environmental conditions when determining the resistance of a waterproofing membrane to jet fuel. Factors such as temperature, exposure time, and concentration of the jet fuel can influence the membrane's performance. Regular inspections and maintenance should also be conducted to identify any signs of degradation or potential weaknesses in the membrane. In summary, while some waterproofing membranes may offer a certain level of resistance to jet fuel, it is crucial to use specialized membranes and implement additional protective measures to ensure optimal performance and protection against the corrosive effects of jet fuel.

- Q: Can a waterproofing membrane be used in chemical or hazardous environments?

- Indeed, a waterproofing membrane proves effective in chemical or hazardous surroundings. Its purpose is to serve as a barrier against water, moisture, and other liquids, including chemicals and hazardous substances. Typically, these membranes are constructed from chemical-resistant materials like polyurethane, PVC, or modified bitumen. This composition ensures their durability and ability to withstand exposure to various chemicals without harm. Nevertheless, it is vital to choose a waterproofing membrane specifically designed for chemical or hazardous environments to guarantee compliance with necessary requirements and standards. Moreover, proper installation and maintenance play a crucial role in ensuring the long-lasting effectiveness of the waterproofing membrane in such settings.

- Q: Can a waterproofing membrane be installed on vertical surfaces without causing sagging or drooping?

- Installing a waterproofing membrane on vertical surfaces without causing sagging or drooping is possible. The key lies in ensuring proper installation techniques and the use of suitable materials. To begin with, it is crucial to choose a high-quality waterproofing membrane designed specifically for vertical applications. These membranes are typically more rigid and offer better adhesion properties, enabling them to firmly adhere to vertical surfaces without sagging. Next, surface preparation plays a vital role in establishing a strong bond between the membrane and the vertical surface. It is important to thoroughly clean the surface, removing any debris, and properly prime it before applying the membrane. This step creates a solid foundation for the membrane and prevents any potential sagging or drooping. In addition, it is essential to follow proper installation techniques. Applying the membrane smoothly and evenly, without excessive stretching or folding, is key to avoiding sagging. Moreover, any seams or overlaps in the membrane should be carefully sealed to maintain a watertight barrier. Furthermore, it is recommended to use mechanical fixings like screws or nails to secure the membrane in place. These fixings provide additional support and help prevent sagging over time. In conclusion, by selecting the right materials, properly preparing the surface, and employing careful installation techniques, it is possible to install a waterproofing membrane on vertical surfaces without causing sagging or drooping.

- Q: Can a waterproofing membrane be applied on top of roofing materials?

- Yes, a waterproofing membrane can be applied on top of roofing materials. In fact, this is a common practice in the construction industry. The primary purpose of a waterproofing membrane is to provide an additional layer of protection against water infiltration, which is especially important in areas prone to heavy rainfall or where the roof is exposed to extreme weather conditions. By applying a waterproofing membrane on top of roofing materials, it creates a barrier that prevents water from seeping through the roof and causing damage to the underlying structure. Additionally, depending on the type of waterproofing membrane used, it can also provide added insulation and improve the overall energy efficiency of the building. It is important to note that proper installation and adherence to manufacturer's guidelines are crucial to ensure the effectiveness and longevity of the waterproofing system. Therefore, it is recommended to consult with a professional roofing contractor or waterproofing specialist to determine the most suitable membrane and installation method for your specific roofing materials and conditions.

- Q: Can a waterproofing membrane be used on below-grade foundations?

- Yes, a waterproofing membrane can be used on below-grade foundations. In fact, it is recommended to use a waterproofing membrane on below-grade foundations to prevent water infiltration and protect the foundation from moisture damage. The membrane acts as a barrier, effectively preventing water from seeping into the foundation walls and causing issues such as leaks, mold, and structural damage. Additionally, waterproofing membranes are designed to withstand the high water pressure typically found in below-grade environments, making them an ideal solution for protecting foundations in basements and other below-ground structures.

- Q: Can waterproofing membranes be used on expansion joints?

- Indeed, expansion joints can benefit from the utilization of waterproofing membranes. These joints serve the purpose of accommodating movement while safeguarding against harm brought about by the expansion or contraction of construction materials due to thermal fluctuations. By applying waterproofing membranes to these joints, a protective barrier is established, effectively impeding the infiltration of water. This serves to preserve the joint's structural integrity and prevent water-induced damage to adjacent areas. It is imperative to carefully select a flexible waterproofing membrane that can endure the joint's movements without incurring cracks or deterioration. Furthermore, the employment of proper installation techniques is crucial to ensuring a watertight seal around the expansion joint.

- Q: How does a waterproofing membrane perform in areas with high temperature fluctuations?

- A waterproofing membrane performs well in areas with high temperature fluctuations due to its ability to withstand expansion and contraction without compromising its integrity. The membrane's flexibility and durability allow it to adapt to the changing temperatures, preventing cracks and leaks that could lead to water damage.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Yes, a waterproofing membrane can be used on terraces or patios. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and leakage. Terraces and patios are exposed to various weather conditions, including rain and snow, which can lead to moisture seeping into the underlying structure. A waterproofing membrane acts as a barrier, preventing water from penetrating the surface and protecting the integrity of the terrace or patio. It helps to extend the lifespan of the structure and prevents costly repairs in the long run. Additionally, using a waterproofing membrane also helps to create a more comfortable and usable space, as it eliminates the risk of water accumulation and potential slip hazards. Overall, investing in a high-quality waterproofing membrane is a wise decision for anyone looking to protect their terrace or patio from water damage.

- Q: Can a waterproofing membrane be used for loading dock levelers and pit walls?

- Yes, a waterproofing membrane can be used for loading dock levelers and pit walls. Waterproofing membranes are designed to provide a protective barrier against moisture and water infiltration. By applying a waterproofing membrane to loading dock levelers and pit walls, it helps to prevent water seepage and potential damage caused by moisture. This is particularly important in areas where water exposure is a concern, such as loading docks and pits where there may be constant exposure to rain, snow, or water from cleaning activities. The waterproofing membrane creates a barrier that keeps the underlying structures dry and protects them from potential water-related issues, such as corrosion, mold growth, and deterioration.

- Q: Can a waterproofing membrane be applied in cold weather conditions?

- Applying a waterproofing membrane in cold weather is possible, but the temperature range may differ depending on the product and manufacturer guidelines. Certain membranes can endure cold temperatures and be applied as low as -20 degrees Celsius (-4 degrees Fahrenheit), while others may have a higher minimum application temperature. Following the manufacturer's instructions is crucial, as well as ensuring the surface is adequately prepared and free from ice, snow, or moisture. Consulting with an experienced professional contractor who has worked with waterproofing membranes in cold weather conditions is also recommended for optimal results.

Send your message to us

Vulcanized/Sulfuretted EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords