High Elastomeric EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

This waterproof coiled material is of high elasticity with best performance among high polymer waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber of ‘CHEN SHENG’ brand is produced with the use of the most advanced continuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,performances reach or exceed the demands of GB18173.1-2012 standard.

Characteristics for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

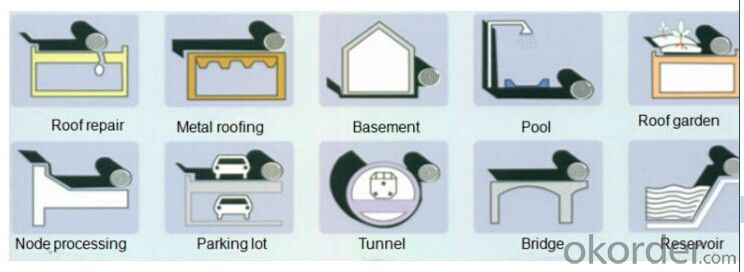

Application for EPDM Waterproof Membrane

It is widely used in roofs, basement, toilet, swimming pool, and all kinds of industry and civil building waterproofing, reservoir, bridge, underground, tunnel and dam waterproofing, especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used on insulation surfaces?

- Yes, a waterproofing membrane can be used on insulation surfaces. It provides an additional layer of protection to prevent moisture infiltration and damage to the insulation material.

- Q: Can a waterproofing membrane be used on roofs with skylights?

- Yes, a waterproofing membrane can be used on roofs with skylights. The membrane is typically installed around the skylight opening to ensure a watertight seal and prevent any leaks or water damage.

- Q: Can a waterproofing membrane be used on bridges?

- Yes, a waterproofing membrane can be used on bridges. Waterproofing membranes are commonly used in bridge construction and rehabilitation projects to protect the bridge deck from water infiltration. These membranes are designed to provide a seamless and durable barrier against water, preventing moisture from reaching the underlying bridge structure. By applying a waterproofing membrane on the bridge deck, it helps to extend the lifespan of the bridge by minimizing the damage caused by moisture and preventing corrosion of the reinforcement steel. Additionally, waterproofing membranes can also help to reduce the potential for freeze-thaw damage, cracking, and deterioration of the bridge deck. Overall, the use of a waterproofing membrane on bridges is an effective solution to ensure the long-term durability and structural integrity of the bridge.

- Q: Can a waterproofing membrane be used on cement board surfaces?

- Yes, a waterproofing membrane can be used on cement board surfaces. Cement board is a commonly used material in construction, particularly in areas prone to moisture such as bathrooms and kitchens. While cement board itself is water-resistant, it is not completely waterproof. Therefore, using a waterproofing membrane can provide an additional layer of protection against water damage. A waterproofing membrane is a thin layer of material that is applied to the surface of the cement board. It is designed to prevent water from penetrating the board and reaching the underlying structure. This is especially important in areas where water exposure is frequent, such as shower stalls or backsplashes. There are different types of waterproofing membranes available, including liquid-applied membranes and sheet membranes. Liquid-applied membranes are typically applied with a brush or roller, while sheet membranes are rolled onto the surface and adhered using an adhesive or thinset mortar. When applying a waterproofing membrane to a cement board surface, it is important to follow the manufacturer's instructions and ensure proper adhesion. This may involve cleaning and priming the surface beforehand, as well as allowing sufficient drying time between coats. In conclusion, using a waterproofing membrane on cement board surfaces can help protect against water damage and prolong the life of the construction. It is a recommended practice, especially in areas prone to moisture, and can provide added peace of mind for homeowners and contractors alike.

- Q: How does a waterproofing membrane handle water infiltration from below?

- A waterproofing membrane is designed to effectively handle water infiltration from below by creating a barrier that prevents water from seeping through the surface it is applied to. The membrane is typically made of a flexible and durable material that can resist water pressure and remain intact. It is installed in such a way that it covers the entire surface area, forming a continuous and impermeable layer. This prevents water from penetrating through the membrane and reaching the underlying structure, effectively protecting it from potential damage caused by water infiltration.

- Q: Are waterproofing membranes resistant to thermal cycling?

- Yes, waterproofing membranes are generally resistant to thermal cycling. These membranes are designed to withstand changes in temperature without losing their effectiveness. Thermal cycling refers to the repeated expansion and contraction of materials due to temperature fluctuations. Waterproofing membranes are engineered to have excellent dimensional stability, which means they can expand and contract with minimal deformation. This resistance to thermal cycling ensures that the membranes maintain their integrity and prevent water penetration, even in extreme temperature conditions. However, it is important to note that the specific resistance to thermal cycling can vary depending on the type and quality of the waterproofing membrane used.

- Q: Can a waterproofing membrane be used for highway or road projects?

- Yes, a waterproofing membrane can be used for highway or road projects. It acts as a protective layer against water infiltration, preventing damage to the road structure and increasing its lifespan. Additionally, it helps to reduce maintenance costs and provides a smoother and safer driving surface.

- Q: What is the lifespan of a waterproofing membrane in extreme weather conditions?

- The lifespan of a waterproofing membrane in extreme weather conditions can vary depending on various factors such as the quality of the membrane, the intensity and duration of the weather conditions, and the maintenance and care provided to the membrane. In general, high-quality waterproofing membranes designed for extreme weather conditions can have a lifespan of 20-30 years or more. These membranes are typically made from durable materials such as modified bitumen, PVC, EPDM, or TPO, which are specifically engineered to withstand harsh weather elements. However, it is important to note that extreme weather conditions, such as heavy rain, intense sunlight, freezing temperatures, or strong winds, can accelerate the wear and tear of the membrane. For example, prolonged exposure to UV radiation can cause the membrane to degrade and lose its effectiveness over time. Regular maintenance and inspections are crucial to prolonging the lifespan of the waterproofing membrane in extreme weather conditions. By promptly addressing any signs of damage, such as cracks, tears, or leaks, and conducting regular cleaning and resealing, the membrane can be better protected against the harsh effects of extreme weather. Furthermore, proper installation techniques and following manufacturer's guidelines are essential to ensure the longevity of the waterproofing membrane. Hiring experienced professionals who are familiar with installing membranes in extreme weather conditions can greatly contribute to the durability and lifespan of the membrane. Ultimately, while a high-quality waterproofing membrane can withstand extreme weather conditions for several decades, it is important to monitor its condition regularly, provide proper care and maintenance, and promptly address any issues that arise to maximize its lifespan.

- Q: Does a waterproofing membrane also protect against moisture and humidity?

- Yes, a waterproofing membrane is specifically designed to protect against moisture and humidity. It acts as a barrier, preventing water penetration and moisture buildup, thus effectively safeguarding the underlying structure from potential damage caused by moisture and humidity.

- Q: Can waterproofing membranes be used on concrete pipes?

- Yes, waterproofing membranes can be used on concrete pipes. These membranes provide a protective barrier against water infiltration, preventing any potential leakage or damage to the concrete pipes.

Send your message to us

High Elastomeric EPDM Rubber Roofing Waterproof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords