EPDM Rubber Weldable Waterproofing Membrane for Roof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

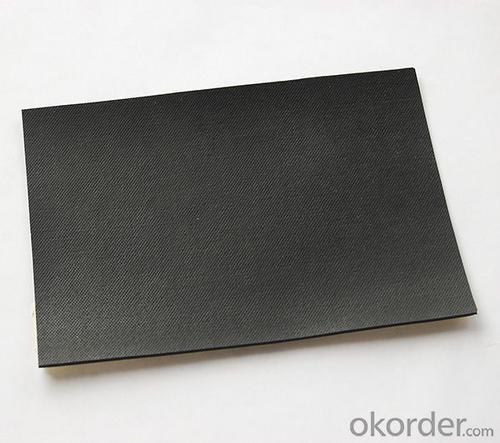

Introduction for EPDM Waterproofing Membrane:

Waterproof membrane for roof adopt the international advanced level cold feed extrusion continuous vulcanization process for the integration of production equipment and technology so that the system density of products is better and the products have no bubble sooth surface, no performance difference between vertical and horizontal.

Characteristic of EPDM Waterproofing Membrane:

1>Excellent anti-aging performance, service life up to 50 years

2>Working well with in -40°C to 100°C,it can be constructed with a single layer in ambient temperature. 3>Waterproofing on various kinds of underground project,industrial of civil buildings and structures. 4>high extension rate, high tensile strength, small size changes at heat treatment

5>Good plant roots penetrability resistance and can be made waterproofing layer of planting roof

6>Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem . 7>Good low temperature flexibility, and good performance of adapting to ambient temperature changes. 8>Convenient application ,solid joint, no environment pollution

9>chemical corrosion Resistance, can be used for special occasions

Specification of EPDM Waterproofing Membrane:

Type | Waterproof membrane for roof |

Material | Ethylene, propylene and a small amount dicyclopentadiene |

Surface | Fleece back,plain black back |

Thickness | 1.2mm,1.5mm,2.0mm |

Width | 1.2m, 2m-4m, customized |

Length | 20m/roll |

Usage | basements, ponds, Lake, steel structure roofing, underground, tunnels |

Weight(kg/roll) | 1.2mm 37-38 |

1.5mm 40-41 | |

2.0mm 58-59 |

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for bathrooms or showers?

- Yes, a waterproofing membrane can be used for bathrooms or showers. It is designed to create a protective barrier against water damage, ensuring that the walls, floors, and other surfaces remain dry and free from moisture penetration. This helps to prevent mold, mildew, and structural issues caused by water leakage, making it an essential component in bathroom and shower construction or renovation.

- Q: Does a waterproofing membrane have any impact on the indoor air quality?

- The impact of a waterproofing membrane on indoor air quality should not be underestimated. Waterproofing membranes, commonly used to prevent water infiltration in moisture-prone areas like basements, roofs, and foundations, are typically made of synthetic materials like polyethylene or polypropylene. Unfortunately, these materials can release volatile organic compounds (VOCs) into the air. VOCs are chemicals that can evaporate at room temperature and have negative effects on indoor air quality. They contribute to the formation of indoor air pollutants, including formaldehyde and benzene. Prolonged exposure to VOCs can result in health issues such as eye, nose, and throat irritation, headaches, dizziness, and respiratory problems. However, it's important to note that not all waterproofing membranes have the same impact on indoor air quality. Some manufacturers have developed low VOC or VOC-free membranes that aim to minimize the release of harmful chemicals. These products undergo rigorous testing to meet stringent air quality standards. In addition, proper installation and ventilation are crucial in mitigating any potential negative impact on indoor air quality. Adequate ventilation systems help eliminate VOCs and other pollutants, preventing them from accumulating and causing health problems. Therefore, when considering the installation of a waterproofing membrane, it's crucial to select a product that has been tested for low VOC emissions and ensure proper ventilation is in place to maintain good indoor air quality. Seeking guidance from professionals in the field can assist in choosing the most suitable waterproofing solution for specific needs while minimizing any potential impact on indoor air quality.

- Q: Can a waterproofing membrane be installed in wet conditions?

- Yes, a waterproofing membrane can be installed in wet conditions. However, it is important to ensure that the surface being waterproofed is dry and free of any standing water before the installation. This is because the membrane needs a clean and dry surface to adhere properly and create an effective barrier against water. If the surface is wet, it may prevent the membrane from bonding correctly, leading to potential leaks or failures in the waterproofing system. Therefore, it is recommended to wait for the surface to dry or use appropriate methods to remove any excess moisture before installing the waterproofing membrane.

- Q: Does a waterproofing membrane prevent efflorescence or mineral deposits on surfaces?

- Efflorescence or mineral deposits on surfaces can be prevented with the use of a waterproofing membrane. Efflorescence occurs when water-soluble salts dissolve in concrete or masonry materials and migrate to the surface, leaving behind a white residue. By stopping water from penetrating the surface, a waterproofing membrane reduces the amount of water available to dissolve these salts and carry them to the surface, effectively reducing the occurrence of efflorescence. Similarly, mineral deposits can form when water with dissolved minerals evaporates, leaving behind the minerals as residue. A waterproofing membrane prevents water from reaching the surface, thus minimizing the formation of mineral deposits. It is important to note, however, that a waterproofing membrane may not completely eliminate these issues if there are underlying problems with the material or water source. To ensure the effectiveness of the waterproofing membrane in preventing efflorescence or mineral deposits, regular maintenance and proper installation are crucial.

- Q: Are waterproofing membranes resistant to chemical degradation?

- Yes, waterproofing membranes are typically resistant to chemical degradation. These membranes are specifically designed to provide a barrier against water and other liquids, and they are often made from materials that have excellent chemical resistance. The membranes are engineered to withstand exposure to various chemicals, including acids, alkalis, and solvents, without undergoing significant degradation or damage. This chemical resistance ensures the long-term durability and effectiveness of the waterproofing system, making it suitable for a wide range of applications, such as basements, roofs, and underground structures. However, it is important to note that the specific chemical resistance may vary depending on the type of waterproofing membrane and the specific chemicals it is exposed to. Therefore, it is crucial to carefully select the appropriate membrane based on the intended application and the specific chemical environment it will be exposed to. Additionally, proper installation and maintenance are essential to ensure the continued chemical resistance and performance of the waterproofing membrane.

- Q: Can a waterproofing membrane be used in chemical or hazardous environments?

- Yes, a waterproofing membrane can be used in chemical or hazardous environments. Waterproofing membranes are designed to provide a barrier against water, moisture, and other liquids, which can also include chemicals and hazardous substances. These membranes are typically made of materials that are resistant to chemicals, such as polyurethane, PVC, or modified bitumen, to ensure they can withstand exposure to various chemicals without being damaged or compromised. However, it is important to select a waterproofing membrane specifically designed for chemical or hazardous environments to ensure it meets the necessary requirements and standards for such applications. Additionally, proper installation and maintenance are crucial to ensure the effectiveness and longevity of the waterproofing membrane in these environments.

- Q: Can a waterproofing membrane be used on galvanized surfaces?

- Yes, a waterproofing membrane can be used on galvanized surfaces. Galvanized surfaces are typically used to protect metal from corrosion, and applying a waterproofing membrane can further enhance the protective properties of the galvanized coating. The membrane can provide an additional layer of defense against water penetration, preventing moisture from reaching the galvanized surface and potentially causing rust or other damage. However, it is important to ensure that the waterproofing membrane is compatible with the galvanized surface and is specifically designed for use in such applications. It is also recommended to consult with the manufacturer or a professional to ensure proper installation and compatibility before applying a waterproofing membrane on galvanized surfaces.

- Q: Can a waterproofing membrane be used for food processing facilities?

- Yes, a waterproofing membrane can be used for food processing facilities. Waterproofing membranes are commonly used in various industries, including food processing, to ensure protection against water penetration and moisture damage. In food processing facilities, where hygiene and cleanliness are of utmost importance, waterproofing membranes can be applied to floors, walls, and ceilings to prevent water or other liquids from seeping into the building structure. Waterproofing membranes create a protective barrier that effectively seals the surfaces, preventing the growth of mold, mildew, and bacteria that can contaminate food products. They also help in maintaining a clean and dry environment, reducing the risk of slips, falls, and accidents caused by wet surfaces. Food processing facilities often deal with water-intensive processes such as cleaning, washing, and sanitizing, making it crucial to have a reliable waterproofing system in place. Additionally, waterproofing membranes can offer resistance to chemicals, oils, and other substances commonly used in food processing, ensuring long-term durability and protection. It is important to note that when selecting a waterproofing membrane for a food processing facility, it is necessary to choose a product that complies with industry standards and regulations. The membrane should be food-grade and certified safe for contact with food products to avoid any potential contamination risks. Overall, using a waterproofing membrane in food processing facilities can help maintain hygienic conditions, protect the building structure, and ensure compliance with health and safety regulations.

- Q: Can a waterproofing membrane prevent leaks from occurring?

- Yes, a waterproofing membrane can prevent leaks from occurring. A waterproofing membrane is a thin layer of material that is applied to a surface to make it completely impermeable to water. It acts as a barrier, preventing water from seeping through and causing leaks. When properly installed and maintained, a waterproofing membrane can effectively protect various structures such as roofs, basements, bathrooms, or foundations from water damage. It is designed to withstand the forces of nature, including rain, snow, and moisture, and can significantly reduce the risk of leaks and water infiltration. However, it is important to note that the effectiveness of a waterproofing membrane also depends on the quality of the product, proper installation, and regular maintenance.

- Q: Are waterproofing membranes resistant to alkalis?

- Yes, waterproofing membranes are generally resistant to alkalis. Alkalis are substances with a high pH level, such as sodium hydroxide or potassium hydroxide, and can be found in various construction materials, including concrete. Waterproofing membranes are specifically designed to provide a protective barrier against water and other potentially damaging substances. They are typically made from materials such as modified bitumen, PVC, or EPDM, which have excellent resistance to alkalis. This resistance ensures that the waterproofing membrane remains intact and effective, even when exposed to alkaline substances. It is important to choose a waterproofing membrane that is specifically designed for alkali resistance when working with materials or environments that contain high levels of alkalis.

Send your message to us

EPDM Rubber Weldable Waterproofing Membrane for Roof

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords