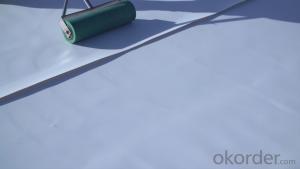

TPO Roofing Membrane White with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of TPO Roofing Membrane White with High Strength:

We have more than 15 years experience in development & manufacture construction materials such as waterproof membrane,waterproof coils,waterproof panels,waterproof coating,geomembrane,geotextiles etc.Depending on our full set production line,well equipped laboratory,cooperation with institute&college and experienced employees,we have successfully developed and consolidated domestic and foreign market.

With a high-tech team of research and development,we have our patent technology, the spray application waterproof membrane.They are the most advanced technology in tunnel and underground projects.

Quality is our life,customer satisfaction is our goal, to build the world be more beautiful is our responsibility!

Main Features of TPO Roofing Membrane White with High Strength:

1.high reflectivity,anti-ultraviolet radiation,do not need to be protection,energy saving and environmental protection.

2.long-term weathering resistance,resistance to ultravoilet radiation and heat aging,density is small.

3..high elasticity,high strength,high elongation,good suppleness.

4.effectively resist harmful chemicals,industrial pollutants erosion,wear resistance,resistance to puncture.

5.with automatic quench.

Specifications of TPO Roofing Membrane White with High Strength:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Applications of TPO Roofing Membrane White with High Strength:

1.Roofs, Basement, Toilets

2. Industrial and civil building waterproofing

3. Geosynthetic liner for swimming pool, channels, irrigation system

4. Especially suitable for projects with high requirements in durability, anti-corrosion and deformation.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can waterproofing membranes be used on expansion joints?

- Yes, waterproofing membranes can be used on expansion joints. Expansion joints are designed to accommodate movement and prevent damage caused by thermal expansion or contraction of building materials. Waterproofing membranes can be applied to expansion joints to create a barrier against water infiltration, which helps to maintain the structural integrity of the joint and prevent water damage to surrounding areas. It is important to select a waterproofing membrane that is flexible and able to withstand the movement of the joint without cracking or deteriorating. Additionally, proper installation techniques should be followed to ensure a watertight seal around the expansion joint.

- Q: Can a waterproofing membrane be used on concrete surfaces?

- Concrete surfaces can indeed benefit from the application of a waterproofing membrane. These membranes are frequently employed to safeguard concrete constructions, such as basements, foundations, and roofs, against water-related harm. Their purpose is to establish a barrier that prevents water from infiltrating the concrete surface. By doing so, they aid in averting the accumulation of moisture, the growth of mold, and the deterioration of the concrete. Furthermore, these waterproofing membranes can furnish supplementary defense against chemicals, UV rays, and other environmental elements. To accomplish the desired waterproofing outcomes, it is crucial to ensure that the membrane is properly installed and compatible with the specific concrete surface.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- Yes, a waterproofing membrane can help prevent mold or mildew growth by creating a barrier that keeps moisture out. By stopping water infiltration, it reduces the conditions necessary for mold and mildew to thrive, thus providing protection against their growth.

- Q: Is a waterproofing membrane breathable?

- No, a waterproofing membrane is generally not breathable as its primary purpose is to prevent water from passing through.

- Q: Can a waterproofing membrane be used for a swimming pool liner?

- Yes, a waterproofing membrane can be used as a swimming pool liner. Waterproofing membranes are designed to provide a barrier against water penetration, making them suitable for use in swimming pools to prevent leaks and maintain the water integrity.

- Q: Can a waterproofing membrane be used on vinyl surfaces?

- Indeed, one can employ a waterproofing membrane on vinyl surfaces. Vinyl surfaces, including vinyl flooring or vinyl siding, are frequently encountered in both residential and commercial structures. Waterproofing membranes are specifically crafted to establish a barrier against water and moisture, effectively hindering their infiltration into the underlying materials. By applying such membranes onto vinyl surfaces, an extra layer of safeguarding is provided, thereby guaranteeing that the vinyl remains unharmed by water-related issues or decay. Selecting a waterproofing membrane that is compatible with vinyl surfaces is crucial, as is adhering to the manufacturer's instructions for correct application.

- Q: Can a waterproofing membrane be used on different types of surfaces, such as concrete, wood, or metal?

- Yes, a waterproofing membrane can be used on different types of surfaces including concrete, wood, and metal. Waterproofing membranes are designed to provide a protective barrier against moisture and can adhere to various surfaces, ensuring effective waterproofing regardless of the material.

- Q: Can waterproofing membranes be used on wood surfaces?

- Yes, waterproofing membranes can be used on wood surfaces. Waterproofing membranes are versatile products that can be applied to a variety of materials, including wood. They are designed to create a protective barrier that prevents water from penetrating the surface, thereby preventing damage caused by moisture, such as rotting, warping, or mold growth. When applied correctly, waterproofing membranes can effectively seal wood surfaces, making them resistant to water absorption and increasing their durability and lifespan. It is important to choose a waterproofing membrane that is specifically formulated for wood applications and follow the manufacturer's instructions for proper application and maintenance.

- Q: Can a waterproofing membrane be used on asphalt surfaces?

- Yes, a waterproofing membrane can be used on asphalt surfaces. Waterproofing membranes are often used to protect various surfaces, including asphalt, from water damage. They create a barrier that prevents water from seeping into the asphalt, reducing the risk of cracks, deterioration, and other forms of damage caused by moisture.

- Q: Are waterproofing membranes resistant to algae growth?

- Waterproofing membranes generally resist the growth of algae. These membranes are designed to be highly durable and withstand various environmental factors, including algae growth. They are typically made from materials like PVC, TPO, or EPDM, which inherently resist algae and other microbial growth. Additionally, manufacturers often treat waterproofing membranes with anti-algae and anti-fungal agents to further enhance their resistance. However, it's important to note that while these membranes resist algae growth, regular cleaning and maintenance are still necessary to ensure their long-term performance and prevent the accumulation of dirt or debris that could create an ideal environment for algae.

Send your message to us

TPO Roofing Membrane White with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords