T Slot Extruded Aluminum Profiles - High Quality 6000 Series for Industrial Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

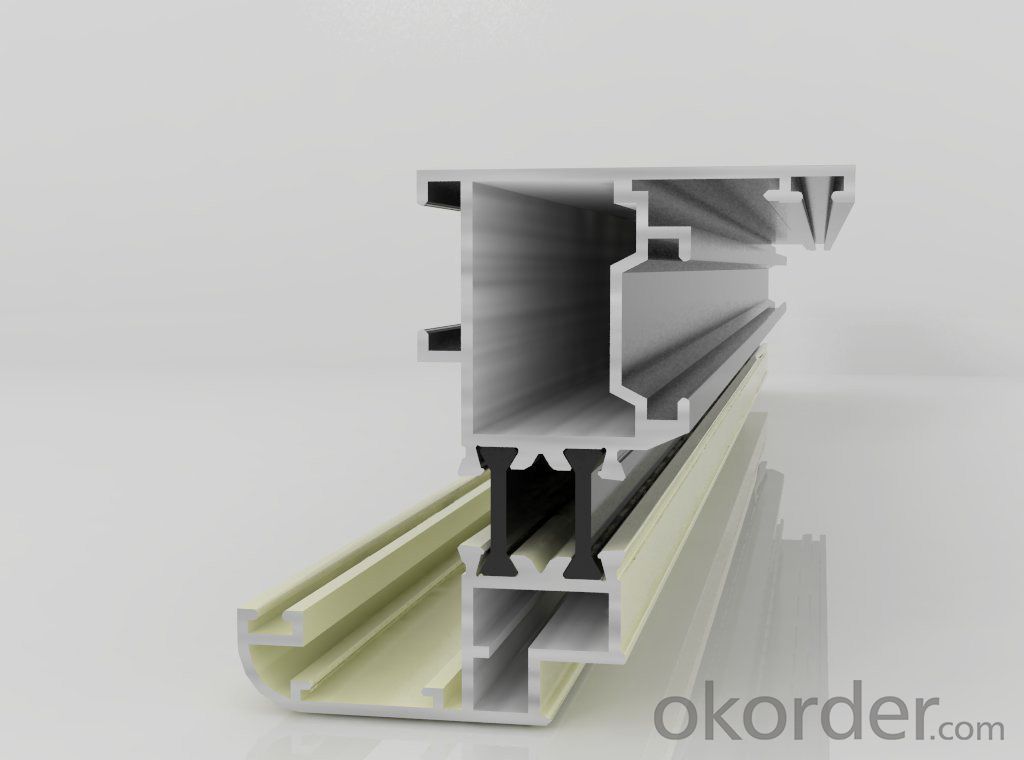

Structure of Aluminum Profile High Quality 6000 Series For Industrial Usages Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminum Profile High Quality 6000 Series For Industrial Usages:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

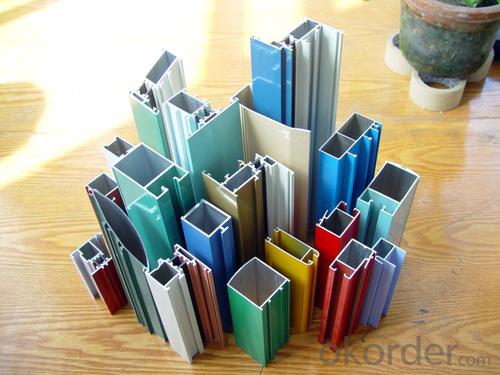

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the Aluminum Profile High Quality 6000 Series For Industrial Usages:

Aluminum Profile High Quality 6000 Series For Industrial Usages Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: How do you prevent galvanic corrosion when combining aluminum profiles with concrete or masonry?

- One effective method to prevent galvanic corrosion when combining aluminum profiles with concrete or masonry is to use a protective barrier. Applying a suitable coating or corrosion-resistant material on the aluminum surface can create a barrier between the aluminum and the concrete/masonry, preventing direct contact and minimizing the risk of galvanic corrosion. Additionally, using isolation materials such as gaskets or non-conductive joint fillers between the aluminum profiles and the concrete/masonry can further help to prevent galvanic corrosion by isolating the dissimilar metals. Regular inspection and maintenance are also essential to identify any potential corrosion issues early on and take necessary preventive measures.

- Q: This question asks for the various types of aluminum profiles that are utilized in roofing systems.

- <p>Aluminum profiles for roofing systems come in various types, each serving specific purposes. Common types include: 1. <strong>Gutter Profiles</strong>: Used for collecting and directing rainwater from the roof. 2. <strong>Fascia Profiles</strong>: Cover the ends of rafters and provide a finished edge to the roof. 3. <strong>Soffit Profiles</strong>: Installed under the eaves to allow ventilation and conceal the underside of the roof. 4. <strong>Purlin Profiles</strong>: Support the roof sheeting and are placed perpendicular to the rafters. 5. <strong>Rafter Profiles</strong>: Mimic traditional wooden rafters and provide structural support. 6. <strong>Roof Ridge Profiles</strong>: Cap the ridge of the roof, where two slopes meet. 7. <strong>Hip and Valley Profiles</strong>: Used at the intersection of two sloping roof surfaces. Each profile is designed to withstand weather conditions and provide durability, with specific dimensions and shapes tailored to the roofing system's requirements.</p>

- Q: What are the regular colors of aluminum profiles?

- The main process is:(1) surface pretreatment: chemical or physical methods are used to clean the surface of the profile and expose the pure matrix to obtain a complete and compact artificial oxide film. The mirror or non light (Ya Guang) surface can also be obtained by mechanical means.(2) anodizing: the surface of the pre processed profiles, in a certain process conditions, the substrate surface anodic oxidation, resulting in a dense, porous, strong adsorption of AL203 film.(3) sealing: the pore space of the porous oxide film produced by anodic oxidation is closed, so that the oxidation film is anti pollution, and the corrosion resistance and wear resistance are enhanced. The film is colorless and transparent, with strong adsorption before sealing film, adsorption and deposition of metal salts in some membrane hole, can make the profile appearance character (silver) show many colors, except such as: black, bronze, golden color and stainless steel etc..

- Q: Acrylic coating principle, coating on the aluminum section, he and fluorocarbon powder spraying, what is the difference

- Acrylic is liquid paint, just spray it onceFluorocarbon is also liquid paint, need to spray 2-4 times, known as two Tu, three TU, four Tu.

- Q: Are aluminum profiles suitable for fencing and gates?

- Yes, aluminum profiles are suitable for fencing and gates. Aluminum is a popular choice for these applications due to its durability, strength, and low maintenance requirements. It is resistant to rust, corrosion, and weathering, making it an excellent choice for outdoor use. Additionally, aluminum profiles offer versatility in terms of design, allowing for various styles and customization options. They are lightweight yet sturdy, making them easy to install and handle. Furthermore, aluminum is a sustainable and environmentally friendly material, as it is 100% recyclable. Overall, aluminum profiles provide a practical and aesthetically pleasing solution for fencing and gates.

- Q: Can aluminum profiles be used for automotive roof racks or cargo systems?

- Automotive roof racks or cargo systems can indeed utilize aluminum profiles. Aluminum, a material known for its durability and lightweight properties, is widely employed in the automotive sector owing to its impressive strength-to-weight ratio. Its resistance to corrosion is especially crucial for roof racks as they are exposed to the elements. Moreover, aluminum profiles can be effortlessly molded and tailored to meet specific specifications, rendering them appropriate for diverse cargo system designs. In summary, owing to their strength, lightweight nature, and resistance to corrosion, aluminum profiles are highly favored for automotive roof racks and cargo systems.

- Q: What are the different shapes available in aluminum profiles?

- There are various shapes available in aluminum profiles, including but not limited to angles, channels, square tubes, rectangular tubes, T-bars, I-beams, round tubes, and custom profiles.

- Q: What are the different machining techniques for aluminum profiles?

- Some of the different machining techniques for aluminum profiles include milling, drilling, turning, and sawing. These techniques are used to shape, cut, and create various features on aluminum profiles, such as holes, slots, chamfers, and intricate designs. Additionally, other techniques like grinding, polishing, and sanding may be employed to achieve the desired surface finish on the aluminum profiles.

- Q: What are the electrical insulation properties of aluminum profiles?

- Compared to plastics or ceramics commonly used in electrical applications, aluminum profiles exhibit relatively low electrical insulation properties due to their high conductivity. This attribute allows for the easy flow of electrical current. Nevertheless, with proper precautions, aluminum profiles can still be effectively utilized in electrical applications. Anodizing or coating the profiles with insulating materials like epoxy or polyurethane can significantly enhance their insulation capabilities. These coatings establish a barrier between the aluminum and the electrical current, minimizing the risk of conductivity. Moreover, aluminum profiles can be combined with other insulating materials to achieve the desired level of electrical insulation. For instance, in electrical wiring systems, aluminum conductors are frequently paired with insulating materials such as PVC or cross-linked polyethylene to ensure reliable insulation. It is crucial to recognize that while aluminum profiles may possess lower electrical insulation properties compared to other materials, they do offer other advantageous characteristics like high strength, lightweightness, and corrosion resistance. Hence, careful consideration needs to be given to the specific application and electrical requirements before selecting aluminum profiles as an electrical insulation material.

- Q: How do you clean and maintain aluminum profiles?

- Here are some straightforward steps to clean and maintain aluminum profiles: 1. Begin by eliminating loose dirt or debris from the aluminum profiles' surface using a soft brush or cloth. 2. Create a cleaning solution by combining warm water with mild dish soap or a non-abrasive cleaner. Avoid using harsh chemicals or abrasive cleaners since they can harm the aluminum finish. 3. Immerse a gentle cloth or sponge into the cleaning solution and delicately scrub the aluminum profiles, ensuring that all corners and crevices are thoroughly cleaned. 4. Rinse the profiles with clean water to remove any soap residue. You can accomplish this by using a hose or a bucket of water. 5. Dry the aluminum profiles entirely using a soft, lint-free cloth. This will prevent the formation of water spots or streaks. 6. For routine maintenance, you can employ a specialized aluminum cleaner or polish to restore the shine and safeguard the surface. Follow the product instructions for optimal outcomes. 7. It is crucial to refrain from using abrasive scrubbers, steel wool, or harsh chemicals as they can scratch or damage the aluminum finish. Additionally, never apply acidic cleaners or vinegar on aluminum since they can cause corrosion. 8. If you happen to notice any scratches or minor damages on the aluminum profiles, you can employ a touch-up paint specifically designed for aluminum to repair them. Follow the manufacturer's instructions for application. Always remember that regular cleaning and maintenance will aid in preserving the appearance and longevity of your aluminum profiles.

Send your message to us

T Slot Extruded Aluminum Profiles - High Quality 6000 Series for Industrial Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords