Wholesale Anodized Aluminum Profiles for Construction Application in Cars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Plate for Construction Application in Cars Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of theAluminium Plate for Construction Application in Cars:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

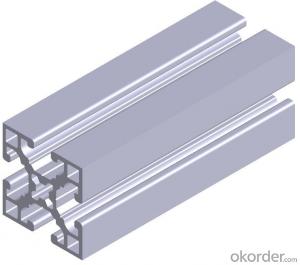

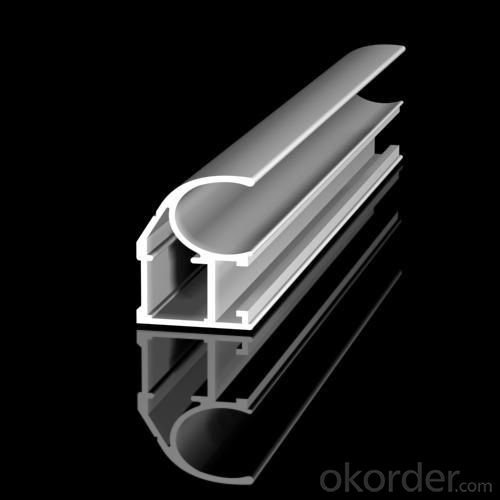

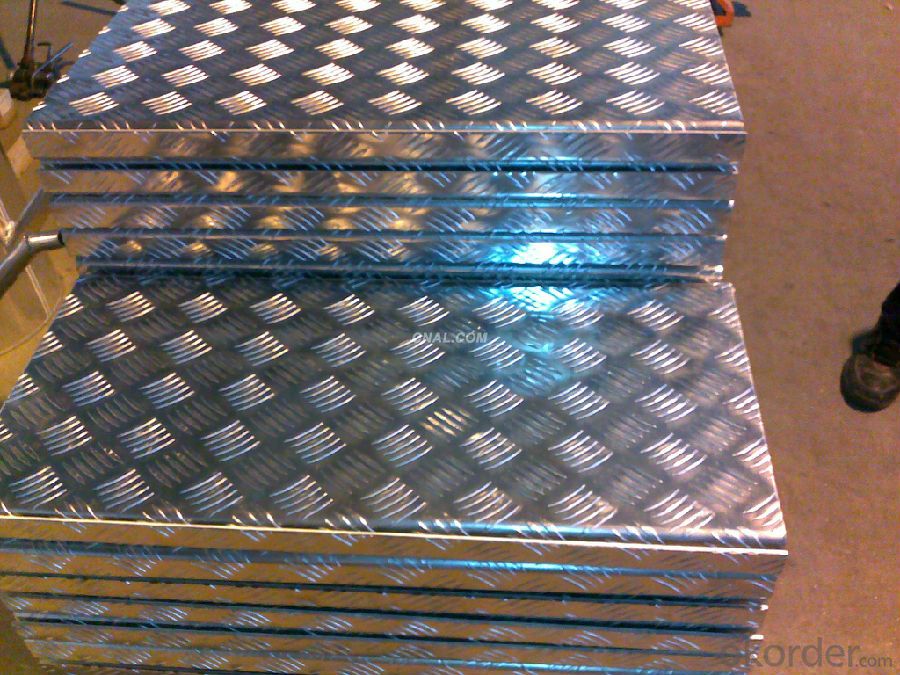

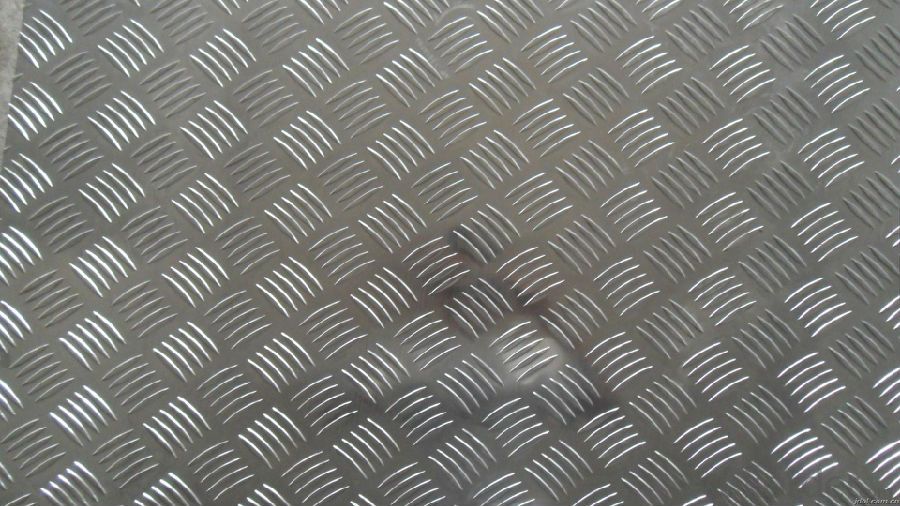

Images of the Aluminium Plate for Construction Application in Cars:

Aluminium Plate for Construction Application in Cars Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are aluminum profiles suitable for lighting fixtures?

- Lighting fixtures can greatly benefit from the use of aluminum profiles. Aluminum, being a lightweight and versatile material, offers numerous advantages for lighting applications. To begin with, aluminum profiles possess excellent thermal conductivity. This means they effectively dissipate the heat generated by the lighting fixtures. Maintaining a cooler operating temperature is crucial as excessive heat can shorten the lifespan and impact the performance of the lighting components. By utilizing aluminum profiles, the longevity and efficiency of the lighting fixtures are enhanced. Moreover, aluminum profiles are resistant to corrosion, making them suitable for both indoor and outdoor lighting fixtures. This corrosion resistance ensures that the fixtures can endure harsh environmental conditions, such as high humidity or moisture exposure, without deteriorating or losing functionality. Additionally, aluminum profiles are easily customizable and can be tailored to meet various lighting requirements. They can be extruded into different shapes and sizes, allowing for flexibility in the design of lighting fixtures. This versatility empowers manufacturers to create sleek and modern lighting solutions that seamlessly integrate into different architectural designs and spaces. Furthermore, aluminum profiles offer aesthetic appeal as they can be powder-coated or anodized in a wide array of colors. This provides a plethora of options to match different interior or exterior design themes. Lastly, aluminum is a sustainable material that can be fully recycled. By choosing aluminum profiles for lighting fixtures, one contributes to reducing environmental impact and supports the principles of sustainability. To summarize, aluminum profiles are highly suitable for lighting fixtures due to their thermal conductivity, corrosion resistance, versatility, aesthetic appeal, and sustainability. This is why they are extensively used in the lighting industry.

- Q: Can aluminum profiles be used in signage or display applications?

- Yes, aluminum profiles can be used in signage or display applications. Aluminum profiles are lightweight, durable, and versatile, making them suitable for various applications such as sign frames, display stands, and exhibition booths. Additionally, aluminum profiles can be easily customized and offer a sleek and modern appearance, making them a popular choice in the signage and display industry.

- Q: This question asks for criteria or methods to determine if a specific aluminum profile is appropriate for a given project.

- <p>To determine if an aluminum profile is suitable for your project, consider the following factors: 1) Load-bearing capacity - Check if the profile can withstand the weight and stress it will be subjected to. 2) Dimensional requirements - Ensure the profile's size and shape match your project's specifications. 3) Corrosion resistance - Verify if the profile is resistant to the environmental conditions it will be exposed to. 4) Surface finish - Confirm if the profile's finish meets your aesthetic and functional needs. 5) Compatibility with other materials - Make sure the profile can be effectively joined or integrated with other materials in your project. Consult with an engineer or the profile manufacturer for specific recommendations based on your project's unique requirements.</p>

- Q: Are aluminum profiles durable?

- Yes, aluminum profiles are highly durable. Aluminum is known for its exceptional strength-to-weight ratio, making it an ideal choice for a variety of applications where durability is essential. Aluminum profiles are resistant to corrosion, which means they can withstand exposure to harsh environmental conditions without deteriorating. Additionally, aluminum profiles have excellent structural integrity, allowing them to withstand heavy loads and impacts without bending or breaking. This makes them highly reliable and long-lasting, making them a popular choice in industries such as construction, automotive, aerospace, and many more.

- Q: Do aluminum profiles come with any certifications?

- Yes, aluminum profiles often come with certifications such as the ISO 9001 quality management system certification, ISO 14001 environmental management system certification, and the RoHS (Restriction of Hazardous Substances) compliance certification. These certifications ensure that the aluminum profiles meet international standards for quality, environmental friendliness, and the absence of hazardous materials.

- Q: Can aluminum profiles be used in the construction of solar panels?

- Yes, aluminum profiles can be used in the construction of solar panels. Aluminum is a lightweight and durable material that is commonly used in various industries, including construction and solar energy. It offers several advantages when used in the manufacturing of solar panels. Firstly, aluminum profiles provide structural support and stability to the solar panel system. They can be easily shaped and formed into various designs, allowing for flexibility in panel assembly. Additionally, aluminum has excellent corrosion resistance, ensuring the longevity and durability of the panels in different weather conditions. Furthermore, aluminum profiles are highly conductive, which is crucial for the efficient functioning of solar panels. They help to dissipate heat generated by the solar cells, preventing overheating and enhancing the overall performance and lifespan of the panels. Moreover, aluminum is a sustainable and eco-friendly material. It can be easily recycled and reused, reducing the environmental impact of solar panel production. This aligns with the principles of renewable energy and sustainability, making aluminum profiles a preferred choice in the construction of solar panels. In conclusion, aluminum profiles can be effectively utilized in the construction of solar panels due to their structural strength, corrosion resistance, thermal conductivity, and sustainability. Their usage ensures the reliability, efficiency, and eco-friendliness of solar panel systems.

- Q: Aluminum profiles and plastic doors and windows which good, what market?

- The thermal insulation and sound insulation effect of plastic steel doors and windows are better than those of aluminum profiles. Window or plain steel is better. Do not do the door, a long time to deformation. The door is not open, the aluminum door is good. This is how many doors and windows I've made

- Q: Are there any fire safety considerations when using aluminum profiles?

- Fire safety considerations must be taken into account when utilizing aluminum profiles. Although aluminum is not combustible, it can still contribute to the spread and intensity of a fire. Aluminum profiles, particularly in construction or industrial settings, can act as fuel for a fire and potentially worsen its severity. One crucial consideration is the fire rating of the aluminum profiles. Fire ratings indicate how long a material can withstand fire exposure before failing. It is vital to choose aluminum profiles with appropriate fire ratings that match the specific application requirements. This guarantees that the profiles can delay the fire's spread, providing valuable time for evacuation and firefighting efforts. Another consideration is the use of suitable insulation materials. Aluminum profiles are often used in building facades, curtain walls, and other structural applications. In these cases, it is important to ensure that the insulation materials used with the aluminum profiles are fire-resistant. This prevents the fire from spreading through the building envelope and reduces the risk of structural failure. Furthermore, fire safety measures should be implemented during installation. Proper firestopping techniques should be applied to seal any gaps or penetrations around the aluminum profiles. This prevents flames, smoke, and hot gases from passing from one compartment to another, limiting the fire's spread. Regular maintenance and inspection of the aluminum profiles are also crucial for fire safety. Any damage or deterioration should be promptly addressed to prevent potential fire hazards. Additionally, adequate fire detection and suppression systems should be in place to detect and control fires in a timely manner. Overall, although aluminum profiles themselves are not combustible, it is imperative to consider various fire safety measures when using them in construction or industrial applications. By selecting suitable fire-rated profiles, using fire-resistant insulation materials, employing proper installation techniques, and conducting regular inspections, the risk of fire can be minimized, ensuring the safety of occupants and property.

- Q: Can aluminum profiles be used for conveyor belts?

- Yes, aluminum profiles can be used for conveyor belts. Aluminum is a versatile and lightweight material that is commonly used in various industrial applications, including conveyor systems. Aluminum profiles offer several advantages for conveyor belts, such as high strength-to-weight ratio, corrosion resistance, and easy customization. These profiles can be easily fabricated into different shapes and sizes to match the specific requirements of the conveyor system. Additionally, aluminum profiles can be an economical choice as they require less maintenance and have a longer lifespan compared to other materials. Overall, aluminum profiles are a suitable option for conveyor belts due to their durability, versatility, and cost-effectiveness.

- Q: What do the 6063 and T5 represent in the aluminum profile 6063-T5?

- 5: the main alloying element is magnesium6: mainly add alloy elements for silicon and magnesium7: the main alloying elements are zinc and magnesium8: a new alloy that does not belong to the above alloy series2.2, second digits: an alloy that indicates the addition of alloying elements or impurities in the original alloy0: table alloy1: table original alloy by the first amendment2: table original alloy after second modifications2.3,

Send your message to us

Wholesale Anodized Aluminum Profiles for Construction Application in Cars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords