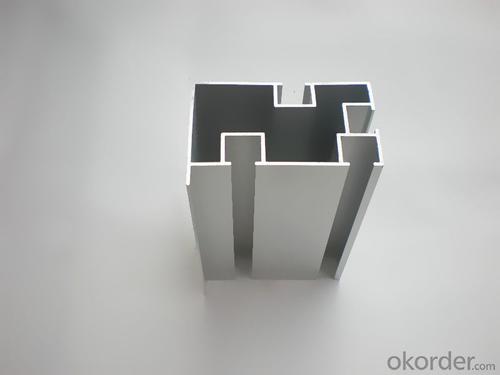

Aluminum Extrusion Profiles Australia - 6000 Series Aluminum Profile Extrusion Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the different bending options available for aluminum profiles?

- There are several bending options available for aluminum profiles, depending on the specific requirements and desired outcomes. Some of the common bending methods for aluminum profiles include: 1. Roll Bending: This method involves passing the aluminum profile between a series of rollers to achieve the desired bend. Roll bending is typically used for larger and thicker profiles, as it provides a gradual and consistent bend. 2. Press Bending: Press bending uses a hydraulic or mechanical press to apply force and shape the aluminum profile into the desired form. This method is suitable for both small and large profiles and can achieve various bend angles. 3. Mandrel Bending: Mandrel bending involves inserting a mandrel, which is a rod or tube, into the aluminum profile to maintain its shape during the bending process. This method ensures precise and uniform bends, making it suitable for complex shapes and tight radius bends. 4. Stretch Bending: Stretch bending applies controlled stretching forces to the aluminum profile, allowing it to flex and bend. This method is often used for profiles with large radii and gentle curves. 5. Rotary Draw Bending: Rotary draw bending utilizes a die and a rotating arm to bend the aluminum profile around a specific radius. This method is highly accurate and commonly used for precise and repeatable bends. 6. Heat Bending: Heat bending involves applying heat to the aluminum profile to soften it before bending. Once the desired bend is achieved, the profile is cooled to retain its new shape. This method is suitable for profiles with complex shapes and sharp angles. Each bending option has its advantages and limitations, and the selection depends on factors such as the profile size, shape complexity, bend angle, and required precision. Consulting with a professional or a bending specialist is recommended to determine the most appropriate bending method for specific aluminum profile applications.

- Q: Aluminum profile connecting piece

- Very little to buy this alone, and only with industrial aluminum suppliers. - selling on Taobao is also a way if the price is appropriate.

- Q: Can aluminum profiles be used in medical equipment manufacturing?

- Yes, aluminum profiles can be used in medical equipment manufacturing. Aluminum is a lightweight and durable material that offers various advantages for medical applications. It is corrosion-resistant, which is crucial in medical settings where equipment is often exposed to chemicals and sterilization processes. Aluminum profiles also provide excellent thermal conductivity, allowing for efficient heat dissipation in medical devices. Furthermore, aluminum profiles can be easily customized to meet specific design requirements, allowing for the creation of complex and precise medical equipment. They can be machined, welded, and formed into various shapes and sizes, making them suitable for a wide range of medical applications, such as surgical instruments, imaging equipment, patient beds, and wheelchairs. In addition to its mechanical properties, aluminum is environmentally friendly and recyclable, aligning with the growing sustainability requirements in the medical industry. It is non-toxic and does not release harmful substances, ensuring the safety of patients and healthcare professionals. Overall, aluminum profiles offer numerous benefits for medical equipment manufacturing, including durability, corrosion resistance, thermal conductivity, customization options, and sustainability.

- Q: Are aluminum profiles suitable for use in exterior insulation systems?

- <p>Yes, aluminum profiles can be used for exterior insulation systems. They offer high strength, durability, and resistance to weathering, making them ideal for external applications. Aluminum profiles are lightweight, easy to install, and can be used to create a robust framework for insulating materials, enhancing the energy efficiency and thermal performance of buildings.</p>

- Q: Can aluminum profiles be used for window frames?

- Yes, aluminum profiles can be used for window frames. Aluminum is a popular material choice for window frames due to its durability, strength, and resistance to corrosion. It is lightweight, easy to shape, and can withstand various weather conditions, making it a suitable option for window frames. Additionally, aluminum profiles can be customized to fit different window sizes and designs, making them a versatile choice.

- Q: Can aluminum profiles be used for automotive roof racks or cargo systems?

- Yes, aluminum profiles can be used for automotive roof racks or cargo systems. Aluminum is a lightweight yet strong material that is commonly used in the automotive industry. It offers good corrosion resistance and can withstand various weather conditions, making it suitable for outdoor applications such as roof racks and cargo systems. Additionally, aluminum profiles can be easily customized and designed to meet specific requirements, making them a popular choice for these applications.

- Q: What are the different colors available for aluminum profiles?

- The different colors available for aluminum profiles can vary depending on the manufacturer or supplier. However, some common color options include natural silver, black, white, bronze, gold, and various shades of gray. Additionally, there are also custom color options available where aluminum profiles can be powder coated or anodized in a wide range of colors to suit specific design requirements.

- Q: Can aluminum profiles be subjected to painting or coating processes to improve their aesthetic appeal and resistance to wear?

- <p>Yes, aluminum profiles can be painted or coated. This process not only enhances their appearance but also significantly improves their durability and resistance to corrosion. Aluminum has a natural oxide layer that provides some protection, but painting or coating can offer additional layers of defense against environmental factors. These coatings can be applied through various methods such as powder coating, anodizing, or electrophoretic deposition, each providing a different finish and level of protection. The choice of coating depends on the specific requirements for appearance, performance, and the environment in which the aluminum profile will be used.</p>

- Q: Can aluminum profiles be used in the production of electronics?

- Yes, aluminum profiles can be used in the production of electronics. They are commonly used for heat sinks, as aluminum has excellent thermal conductivity and can effectively dissipate heat generated by electronic components. Additionally, aluminum profiles can be used for structural support and enclosure purposes in electronic devices.

- Q: What are the weight capacities of aluminum profiles for shelving systems?

- The weight capacities of aluminum profiles for shelving systems can vary depending on the specific design, configuration, and thickness of the profiles. It is best to consult the manufacturer or supplier for accurate and detailed information on weight capacities for a particular shelving system.

Send your message to us

Aluminum Extrusion Profiles Australia - 6000 Series Aluminum Profile Extrusion Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords