Steel Structure with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

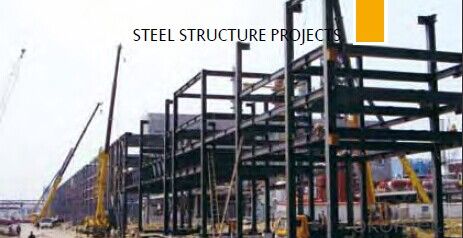

Steel Structure

Description:

1.Length of the welding withnot indication, full welding should be applied

2.Seam without indication is fillet weld, height is 0.75t

3.The cutting angle without indication, radius R=30

4.Cutting angle not specified should be

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

For the Steel structure project of Upper part of external

piperack for air separation and gasifying facilities of

460,000 tons MTO (Methanol to Olefins) project in

Duolun, we provide about 4,500 tons steel structure. It

is a heavy chemical indusry of national energy project.

- Q: How are steel structures designed to be resistant to fire-induced thermal expansion?

- Steel structures are designed to be resistant to fire-induced thermal expansion through various measures. One of the key aspects of this design is the selection of materials that can withstand high temperatures. Steel, being a highly fire-resistant material, is commonly used in the construction of fire-resistant structures. In addition to material selection, the design includes the use of fire protection systems such as fireproof coatings and fire-resistant insulation. These systems are applied to the steel members to provide a protective layer, delaying the rise in temperature and preventing the steel from reaching its critical temperature, where it starts to lose its strength. Furthermore, steel structures are designed with expansion joints and thermal breaks to accommodate thermal expansion and contraction during a fire. Expansion joints allow the steel members to move freely without causing excessive stress, while thermal breaks are used to isolate different parts of the structure to minimize the transfer of heat. Another important design consideration is the structural analysis and calculation of the steel members. Engineers simulate various fire scenarios and determine the potential thermal loads that the structure may experience. This analysis helps in selecting appropriate steel sections and dimensions to ensure that the structure can withstand the expected thermal expansion without failure. Overall, steel structures are meticulously designed to resist fire-induced thermal expansion by using fire-resistant materials, implementing fire protection systems, incorporating expansion joints and thermal breaks, and conducting thorough structural analysis. These measures ensure that the structure can maintain its integrity and stability even in the event of a fire.

- Q: What is the purpose of steel columns in structures?

- The purpose of steel columns in structures is to provide vertical support and stability, distributing the weight of the structure evenly and efficiently. They help to transfer loads from the upper levels to the foundation, ensuring the overall structural integrity and safety of the building. Steel columns are strong, durable, and can withstand heavy loads, making them a popular choice in construction.

- Q: How are steel structures affected by corrosion and rust?

- Steel structures are greatly affected by corrosion and rust. Corrosion is a natural process that occurs when steel is exposed to oxygen and moisture over time. This leads to the formation of rust, which weakens the structural integrity of the steel. Rust occurs when iron in the steel reacts with oxygen in the presence of moisture. The process of rusting causes the steel to deteriorate, leading to a loss of strength and stability. The rust forms on the surface of the steel, and as it expands, it creates cracks and fissures, further compromising the structural integrity. Corrosion and rust can have severe consequences for steel structures. The strength and load-bearing capacity of the steel can be significantly reduced, making the structure more susceptible to collapse or failure. This poses a serious safety risk, especially in critical infrastructures such as bridges, buildings, and industrial facilities. To prevent or minimize the effects of corrosion and rust, various protective measures can be taken. One common method is applying protective coatings such as paint or specialized anti-corrosion coatings. These coatings act as a barrier, preventing moisture and oxygen from reaching the steel surface. Regular inspections and maintenance are also essential to identify and address any signs of corrosion or rust early on. In conclusion, corrosion and rust are major concerns for steel structures as they can compromise their structural integrity. Proper preventive measures and regular maintenance are crucial to ensure the long-term durability and safety of steel structures.

- Q: How do steel structures perform in terms of flexibility for future modifications?

- Steel structures perform exceptionally well in terms of flexibility for future modifications. Due to their inherent strength and versatility, steel buildings can easily accommodate changes in layout, expansion, or retrofitting. The use of steel allows for effortless removal or addition of walls, columns, and other structural elements, ensuring that the building can adapt to evolving needs without compromising its integrity. This flexibility makes steel structures highly desirable for businesses or organizations that anticipate future modifications or expansions.

- Q: What are the considerations when designing steel structures for entertainment venues and performing arts centers?

- When designing steel structures for entertainment venues and performing arts centers, several considerations must be taken into account. Firstly, the capacity and layout of the venue should be carefully planned to accommodate the expected number of attendees and the type of performances that will take place. This involves considering factors such as sightlines, acoustics, and seating arrangements. Secondly, the structural integrity of the steel framework is crucial to ensure the safety of the building and its occupants. The design must account for the loads imposed by the building's own weight, as well as any additional loads from equipment, lighting, and stage effects. Adequate support systems, such as trusses and beams, need to be incorporated to distribute these loads effectively. Furthermore, the design should also consider the flexibility and adaptability of the steel structure. Entertainment venues often require frequent reconfigurations to accommodate different types of performances or events. Therefore, the steel framework should allow for easy modifications and additions, such as removable partitions or adjustable seating arrangements. Additionally, aesthetic considerations play a significant role in designing entertainment venues and performing arts centers. The steel structure should complement the overall architectural design and aesthetic vision of the venue. It may involve incorporating unique features, such as grand entrances, distinctive facades, or iconic roof designs, which enhance the visual appeal and identity of the venue. Lastly, sustainability and energy efficiency should be key considerations. Using steel as a construction material offers several environmental benefits, including its recyclability and durability. Designing with energy-efficient features, such as proper insulation and natural lighting, can also help reduce the building's carbon footprint and operational costs. In conclusion, when designing steel structures for entertainment venues and performing arts centers, considerations such as capacity, safety, flexibility, aesthetics, and sustainability are vital to create functional and visually appealing spaces that provide an exceptional experience for performers and audiences alike.

- Q: What are the design considerations for steel structures in corrosive environments?

- Design considerations for steel structures in corrosive environments include selecting the appropriate corrosion resistant materials, such as stainless steel or galvanized steel, to prevent damage. Protective coatings or paints can also be applied to the steel surface to provide an additional layer of protection. Proper drainage systems and ventilation are essential to prevent water or moisture accumulation, which can accelerate corrosion. Regular inspection and maintenance are crucial to identify and address any signs of corrosion early on. Additionally, the design should incorporate measures to minimize exposure to corrosive elements, such as avoiding direct contact with chemicals or salty air.

- Q: How are steel structures designed and analyzed using computer software?

- Steel structures are designed and analyzed using computer software through a process known as structural analysis and design software. This software enables engineers and architects to efficiently and accurately design steel structures by simulating different loading conditions and analyzing the structural response. The first step in designing a steel structure using computer software is to create a detailed 3D model of the structure. This can be done using computer-aided design (CAD) software, which allows for precise modeling of the structure's geometry. The model includes all the components of the steel structure, such as beams, columns, braces, and connections. Once the 3D model is created, it is imported into a structural analysis software program. This software allows engineers to simulate different loading conditions, such as dead loads, live loads, wind loads, and earthquakes, and analyze how the structure will respond to these loads. The software uses complex mathematical algorithms to calculate the internal forces and displacements within the structure. The structural analysis software also checks the design against various design codes and standards, such as the American Institute of Steel Construction (AISC) code, to ensure that the structure is designed to be safe and structurally sound. It performs checks on factors such as strength, stability, and serviceability to ensure that the structure meets the required design criteria. Based on the results of the structural analysis, the software can provide engineers with valuable insights into the behavior of the steel structure. It can identify potential problem areas, such as areas of high stress or excessive deflection, and suggest modifications to improve the design. Additionally, computer software can aid in the optimization of steel structures. By using algorithms and optimization techniques, it is possible to find the most efficient and cost-effective design for a given set of loading conditions and design criteria. This can help reduce material usage, minimize construction costs, and improve the overall performance of the structure. In conclusion, computer software plays a crucial role in the design and analysis of steel structures. It allows for the creation of detailed 3D models, simulates different loading conditions, analyzes the structural response, checks the design against codes and standards, provides insights into the behavior of the structure, and aids in optimization. By leveraging the power of computer software, engineers and architects can design safe, efficient, and cost-effective steel structures.

- Q: What are the key components of a steel structure?

- The key components of a steel structure include: 1. Structural Members: These are the primary load-bearing elements of a steel structure, such as beams, columns, and trusses. These members are designed to withstand the applied loads and transfer them to the foundation. 2. Connections: Connections are crucial in a steel structure as they join the structural members together. Common types of connections include welded connections, bolted connections, and riveted connections. These connections ensure the stability and integrity of the structure. 3. Foundations: Foundations provide the necessary support and stability to the steel structure. They are typically made of concrete and are designed to distribute the load from the structure to the ground, ensuring the structure's stability. 4. Bracing: Bracing elements, such as diagonal braces and cross-bracing, are used to enhance the lateral stability of the steel structure. They help to resist against forces such as wind and earthquakes, preventing the structure from collapsing or deforming. 5. Cladding: Cladding is the external covering of the steel structure that protects it from weather elements and enhances its aesthetic appearance. Common cladding materials include metal panels, glass, and concrete. 6. Roofing System: The roofing system is an essential component of a steel structure that provides protection against weather conditions. It includes roof trusses, purlins, and roofing materials, such as metal sheets or tiles. 7. Services Integration: Steel structures often require the integration of various services, such as electrical and plumbing systems. Proper coordination and integration of these services ensure the functionality and efficiency of the building. All these components work together to create a durable, stable, and functional steel structure. Their proper design, fabrication, and installation are crucial for the overall performance and safety of the structure.

- Q: How are steel structures used in the construction of residential buildings?

- Due to its numerous advantages, steel structures are commonly employed in the construction of residential buildings. The primary benefit lies in their strength and durability. Steel is an incredibly robust material that can withstand high winds, earthquakes, and other extreme weather conditions. This quality makes it an ideal choice for the construction of secure and sturdy residential buildings. Furthermore, steel structures offer greater flexibility and openness in design. Unlike conventional construction methods, steel can be molded and shaped into various forms, giving architects the freedom to create unique and contemporary designs for residential buildings. This adaptability also allows for easy modifications and expansions in the future, without compromising the structural integrity of the building. Moreover, steel structures are renowned for their construction speed. Prefabricated steel components can be manufactured off-site and swiftly assembled on-site, resulting in a significant reduction in construction time. This not only saves time but also reduces labor costs, making steel structures a cost-effective option for residential construction. Additionally, steel structures are environmentally friendly. Steel is a recyclable material, and its use in construction aids in waste reduction and minimizes the consumption of natural resources. Moreover, steel structures have a longer lifespan compared to other building materials, reducing the need for frequent replacements and renovations. In conclusion, the popularity of steel structures in residential construction stems from their strength, durability, flexibility, construction speed, and environmental benefits. They provide a reliable and secure foundation for residential structures while allowing for innovative and modern designs.

- Q: How are steel structures designed for transportation hubs and terminals?

- Steel structures designed for transportation hubs and terminals are carefully planned and engineered to meet specific requirements. This involves considering factors such as the size and layout of the facility, the anticipated foot traffic and capacity, as well as the functionality and aesthetics desired. The design process typically involves collaborating with architects, engineers, and construction professionals to create a safe and efficient structure. Steel, being a versatile and durable material, is often chosen for its strength, flexibility, and cost-effectiveness. The design takes into account various loads and stresses, including wind, seismic activity, and live loads from vehicles and people. Advanced computer modeling and analysis techniques are utilized to ensure structural integrity and optimize the design. Overall, the design of steel structures for transportation hubs and terminals focuses on creating a high-quality, functional, and visually appealing space that can accommodate the needs of the users while ensuring safety and efficiency.

Send your message to us

Steel Structure with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords