High-end Steel-work with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

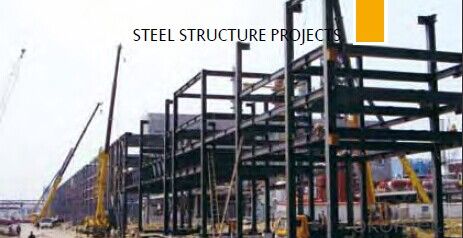

Steel Structure

Description:

1.Length of the welding withnot indication, full welding should be applied

2.Seam without indication is fillet weld, height is 0.75t

3.The cutting angle without indication, radius R=30

4.Cutting angle not specified should be

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

For the Steel structure project of Upper part of external

piperack for air separation and gasifying facilities of

460,000 tons MTO (Methanol to Olefins) project in

Duolun, we provide about 4,500 tons steel structure. It

is a heavy chemical indusry of national energy project.

- Q: How do steel structures provide resistance against torsional loads?

- The inherent strength and stiffness of steel structures enable them to withstand torsional loads. Steel possesses a notable tensile strength, allowing it to endure substantial forces without experiencing significant deformation or failure. Consequently, steel members possess the capacity to resist torsional loads, or twisting forces that induce rotation around an axis. Moreover, steel structures are strategically designed with suitable cross-sectional shapes to enhance their ability to counter torsion. Hollow or solid rectangular and circular sections are commonly utilized in steel beams and columns as they distribute the torsional load across a larger area. These specific shapes are favored due to their superior torsional resistance when compared to alternative shapes like I-sections or channel sections. Furthermore, the torsional resistance of steel structures can be further reinforced through the incorporation of supplementary elements. For example, steel beams can be connected to steel bracing systems or shear walls, which augment rigidity and disperse torsional forces throughout the structure. This enhancement contributes to the overall torsional stability of the steel structure. In conclusion, steel structures effectively combat torsional loads thanks to the high tensile strength of the material, the appropriate cross-sectional shapes of the members, and the integration of additional reinforcement elements. These characteristics ensure that steel structures can endure twisting forces and uphold their structural integrity.

- Q: How are steel structures used in temporary and relocatable buildings?

- Steel structures are commonly used in temporary and relocatable buildings due to their durability, strength, and versatility. These structures provide a sturdy framework that can withstand various weather conditions and support the weight of the building. Steel allows for easy assembly and disassembly, making it ideal for temporary structures that need to be quickly erected and dismantled. Furthermore, steel structures can be easily transported and relocated to different sites, making them a cost-effective solution for temporary and relocatable buildings.

- Q: How do steel structures contribute to the overall energy efficiency of a building?

- Steel structures can contribute significantly to the overall energy efficiency of a building in several ways. Firstly, steel is a highly durable and long-lasting material, which means that steel structures require minimal maintenance and replacement over time. This durability reduces the energy consumption associated with repairs and replacements, ultimately increasing the overall energy efficiency of the building. Additionally, steel is a lightweight material compared to other construction materials like concrete or wood. This lightweight characteristic allows for more efficient transportation and installation, reducing the energy consumption associated with construction processes. The use of steel structures also allows for greater flexibility in design and construction, enabling architects and engineers to optimize energy efficiency by incorporating features such as large windows for natural lighting and ventilation. Furthermore, steel structures have excellent thermal properties. They have a high thermal conductivity, which means they can efficiently transfer heat and cold across the building. This property allows for better temperature regulation and energy management within the building. Steel structures can be designed to incorporate insulation materials effectively, reducing heat loss during winter and heat gain during summer. With proper insulation, the energy required for heating and cooling can be significantly reduced, leading to increased energy efficiency. Moreover, steel is a recyclable material, and its production process has become more environmentally friendly over the years. The recycling of steel reduces the need for raw material extraction and the energy-intensive process of steel production from scratch. This contributes to the overall energy efficiency of a building by reducing the embodied energy and carbon footprint associated with construction. In conclusion, steel structures contribute to the overall energy efficiency of a building through their durability, lightweight nature, thermal properties, and recyclability. By reducing the energy consumption required for maintenance, transportation, heating, and cooling, steel structures can help create more sustainable and energy-efficient buildings.

- Q: What is the difference between single Bangang structure and composite plate of steel structure

- Single board is a single color steel plate, composite board in accordance with a variety of insulation materials, rock wool, glass fiber, foam materials, composite board insulation, sound insulation effect is good, the price gap is great,

- Q: What are the advantages and disadvantages of using pre-engineered steel structures?

- Using pre-engineered steel structures has both advantages and disadvantages. One significant benefit is their exceptional durability, allowing them to withstand harsh weather conditions like hurricanes, earthquakes, and heavy snow loads. Additionally, steel structures resist rot, pests, and fire, making them a safer option for buildings. Another advantage is the cost-effectiveness of pre-engineered steel structures. Compared to traditional construction methods, they are typically less expensive since their components are manufactured off-site and then assembled on-site. This also significantly reduces construction time, saving both time and money. Moreover, pre-engineered steel structures offer great flexibility in terms of design and layout. The steel components can be easily customized to meet specific needs and can be modified or expanded in the future. This provides greater adaptability and versatility compared to other construction methods. However, there are also some disadvantages to consider. One drawback is the limited aesthetic options. Steel structures are often associated with an industrial or commercial look, which may not be suitable for all building types or desired architectural styles. Another disadvantage is the potential for corrosion. While steel structures are generally resistant to rust and corrosion, proper maintenance is crucial to prevent any potential issues. Regular inspections, cleaning, and applying protective coatings are necessary. Additionally, pre-engineered steel structures may not be suitable for all locations or environments. For instance, in areas with high seismic activity, additional engineering and reinforcement may be required to ensure the structure's stability. Similarly, extreme climates may necessitate additional insulation or heating and cooling systems to maintain comfortable indoor temperatures. In conclusion, pre-engineered steel structures offer advantages such as durability, cost-effectiveness, and design flexibility. However, they also have disadvantages including limited aesthetic options, potential corrosion issues, and the need for additional engineering considerations in certain locations or environments. Careful evaluation of these factors and consideration of specific project requirements are important before choosing pre-engineered steel structures as a construction method.

- Q: What are the considerations for designing steel structures in areas with high seismic hazard?

- When designing steel structures in areas with high seismic hazard, there are several considerations that need to be taken into account to ensure the safety and stability of the building. These considerations include: 1. Seismic design codes and regulations: It is crucial to comply with the local seismic design codes and regulations established by the governing bodies. These codes provide guidelines for designing structures that can withstand the expected level of seismic activity in the area. 2. Site-specific seismic hazard assessment: Conducting a thorough site-specific seismic hazard assessment is essential. This assessment includes studying the local geological and tectonic conditions, determining the maximum expected earthquake magnitude, estimating ground motion parameters, and identifying site-specific hazards such as liquefaction or landslides. 3. Structural analysis and design: The design of steel structures should consider the dynamic behavior of the building during an earthquake. Structural analysis techniques, such as modal analysis and response spectrum analysis, are utilized to evaluate the response of the structure under seismic forces and determine the appropriate design criteria. 4. Ductility and energy dissipation: Steel structures should be designed to exhibit ductile behavior during an earthquake. Ductility allows the structure to absorb and dissipate seismic energy, preventing sudden failure and reducing the potential for collapse. This can be achieved through the use of special steel moment-resisting frames or steel bracing systems. 5. Connections and detailing: Proper connection design and detailing are crucial for ensuring the integrity of the structure during an earthquake. Connections should be designed to accommodate the expected displacements and deformations of the structure while maintaining their strength and integrity. Special attention should be given to beam-column connections and the anchorage of the structure to its foundation. 6. Geotechnical considerations: The interaction between the structure and the underlying soil plays a significant role in seismic design. Geotechnical investigations should be carried out to assess the soil conditions and determine the appropriate foundation design, taking into account factors like soil liquefaction, soil amplification, and potential slope instability. 7. Quality control and construction practices: Proper quality control measures and construction practices are vital to ensure the integrity of the steel structure. Regular inspections, material testing, and adherence to construction standards are essential to guarantee that the structure is built according to the approved design. In conclusion, designing steel structures in areas with high seismic hazard requires a comprehensive understanding of the local seismic conditions, compliance with seismic design codes, and the implementation of appropriate structural analysis, connection design, and construction practices. By considering these factors, engineers can create robust and resilient steel structures capable of withstanding the potential seismic forces.

- Q: How are steel structures used in the construction of cold storage facilities?

- Steel structures are widely used in the construction of cold storage facilities for several reasons. Firstly, steel is a durable and strong material, capable of withstanding the extreme temperatures and harsh conditions that cold storage facilities require. Steel structures provide the necessary strength and stability to support the heavy loads of refrigeration equipment, insulation materials, and stored products. Additionally, steel structures allow for flexibility in design and construction. They can be customized to fit the specific needs of the cold storage facility, whether it's a small warehouse or a large-scale distribution center. Steel frames can be easily modified or expanded as the facility's storage requirements change over time, making it a cost-effective solution for the long term. Moreover, steel structures offer efficient insulation properties. Insulated panels made from steel can be incorporated into the construction, ensuring optimal thermal insulation and preventing heat transfer from the outside environment. This helps maintain a controlled, low-temperature environment within the storage facility, preserving the quality and freshness of perishable goods. Another advantage of using steel structures in cold storage facilities is their resistance to pests, fire, and moisture. Steel does not provide a food source for pests and is non-combustible, reducing the risk of fire. Additionally, steel is not susceptible to rot or decay caused by moisture, making it a suitable choice for environments where humidity is a concern. In summary, steel structures are essential in the construction of cold storage facilities due to their durability, flexibility, insulation properties, and resistance to pests, fire, and moisture. They provide a reliable and efficient solution to create a controlled environment that preserves the quality and freshness of perishable goods.

- Q: How are steel structures insulated for soundproofing?

- Steel structures can be insulated for soundproofing using various techniques. One common approach is to install acoustic panels or boards made of materials like mineral wool, fiberglass, or foam on the interior surfaces of the steel structure. These panels absorb sound waves and reduce noise transmission. Additionally, resilient channels or sound isolation clips can be used to separate the panels from the steel frame, preventing vibrations and further improving sound insulation. Another method involves using double-layered walls with an air gap between them, which acts as a barrier to sound transmission. Overall, the key is to incorporate materials and design elements that absorb, block, or redirect sound waves to achieve effective soundproofing in steel structures.

- Q: What are the challenges associated with erecting steel structures?

- There are several challenges associated with erecting steel structures. One of the main challenges is the complexity of the construction process. Steel structures often require meticulous planning and coordination to ensure that all components are properly aligned and connected. This involves careful consideration of the structural design, fabrication, transportation, and installation. Another challenge is the weight and size of steel components. Steel structures can be extremely heavy, and transporting and lifting these components can be difficult and require specialized equipment. The size of these components can also pose logistical challenges, especially when working in confined spaces or urban environments. Furthermore, safety is a major concern when erecting steel structures. Workers must adhere to strict safety protocols to prevent accidents and injuries. This includes proper training in using heavy machinery, ensuring proper fall protection, and following safety guidelines during installation. Weather conditions can also present challenges during the erection process. Wind, rain, and extreme temperatures can affect the stability of the structure and pose risks to workers. Therefore, construction schedules must be carefully planned to minimize exposure to adverse weather conditions. Additionally, the cost of erecting steel structures can be a challenge. The materials and equipment required for steel construction can be expensive, and the labor costs associated with skilled workers can also be high. Therefore, careful budgeting and cost management are necessary to ensure the project remains within the allocated financial resources. Overall, erecting steel structures requires careful planning, coordination, and consideration of various challenges. However, with proper preparation and experienced professionals, these challenges can be overcome to successfully complete construction projects.

- Q: Can steel structures be fire-resistant?

- Yes, steel structures can be fire-resistant. Steel is inherently fire-resistant due to its high melting point and low thermal conductivity. Additionally, steel can be coated or treated with fire-resistant materials to enhance its fire resistance. This makes steel structures a popular choice for buildings that require high fire safety standards, such as commercial buildings, warehouses, and high-rise buildings.

Send your message to us

High-end Steel-work with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords