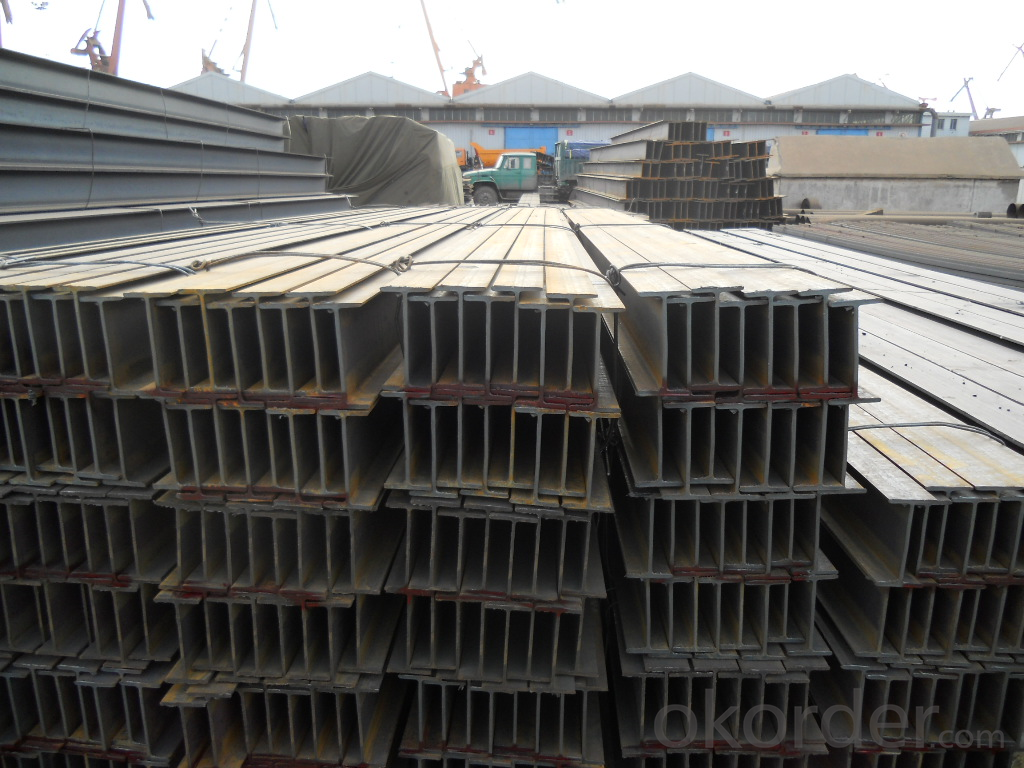

Steel H-Beam for Construction with High Quality and Competitive Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specifications of Steel H-Beam for Construction with High Quality and Competitive Prices

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Usage & Applications of High Quality Hot Rolled Structural Steel H-Beam for Construction

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Steel H-Beam for Construction with High Quality and Competitive Prices

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Steel H-Beam for Construction with High Quality and Competitive Prices

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Images

- Q: Can steel H-beams be used in sports complexes and stadiums?

- Yes, steel H-beams can be used in sports complexes and stadiums. Steel H-beams are commonly used in construction projects due to their strength, durability, and versatility. They provide excellent structural support and can withstand heavy loads, making them suitable for large and complex structures like sports complexes and stadiums. Additionally, steel H-beams can be easily fabricated and assembled, allowing for efficient construction and customization according to specific design requirements. Overall, steel H-beams are a popular choice for sports complexes and stadiums due to their reliability and ability to support the weight and stress associated with such facilities.

- Q: What is the weight of a typical steel H-beam?

- The size and dimensions of a typical steel H-beam can cause its weight to vary. Nevertheless, a common standard is an H-beam that weighs approximately 33 pounds per foot (equivalent to roughly 49 kilograms per meter). It is worth mentioning that the weight can differ depending on factors like the alloy of steel utilized, the manufacturing technique employed, and any extra adjustments or treatments applied to the H-beam. To obtain accurate and precise weight details, it is advisable to refer to the manufacturer's specifications or seek advice from a structural engineer.

- Q: What are the different load types that steel H-beams can withstand?

- Steel H-beams possess excellent versatility and suitability for a wide array of applications due to their ability to withstand diverse load types. These load types that steel H-beams can endure include: 1. Uniformly Distributed Load (UDL): Steel H-beams effectively bear UDL, which is the evenly spread weight across the entire beam length. An example of UDL could be the weight of a floor or a roof. 2. Point Load: Steel H-beams are also capable of resisting point loads, which are concentrated forces applied at a specific point or area on the beam. Instances of point loads include the weight of heavy equipment or machinery placed directly on the beam. 3. Torsional Load: Steel H-beams possess the capacity to withstand torsional loads, which arise from a twisting force applied to the beam. This is crucial for structures experiencing rotational forces, such as bridges or towers subjected to wind or seismic activity. 4. Lateral Load: Steel H-beams can endure lateral loads, also known as horizontal loads that act perpendicular to the beam's axis. This is essential in countering lateral forces caused by wind or earthquakes. 5. Axial Load: Steel H-beams are specifically designed to resist axial loads, which are forces acting along the beam's axis. These loads can be compressive (pushing the beam together) or tensile (pulling the beam apart). Axial loads are commonly encountered in columns or vertical components of a structure. 6. Shear Load: Steel H-beams exhibit the capability to withstand shear loads, which transpire when two forces act in opposite directions parallel to the beam's cross-section. If not appropriately considered in the design, shear forces can cause beam deformation or failure. It is important to acknowledge that the load capacity of steel H-beams varies depending on factors such as beam size, shape, steel type, and specific design considerations of the structure. Thus, consulting engineering specifications and calculations is crucial to ensure the appropriate selection and application of H-beams based on the specific load requirements of a given project.

- Q: What are the different types of steel H-beams available?

- There exists a variety of steel H-beams, each possessing distinctive characteristics and applications. 1. Standard H-beams, widely used and versatile, come in various sizes and dimensions. They find application in the construction industry, providing structural support for buildings and bridges. 2. Wide flange beams, also known as W-beams, possess broader flanges compared to standard H-beams. This design enhances stability and support, rendering them suitable for heavy-duty applications like high-rise buildings, industrial structures, and platforms. 3. I-beams, while not technically H-beams, share a similar shape and are often grouped together. I-beams have a narrower profile, with a flange on one side and a web on the other. They are frequently employed in steel construction projects, including beams, columns, and joists. 4. Tapered H-beams feature a tapered shape, with diminishing flange and web thickness from top to bottom. They serve applications where weight reduction is crucial, such as aerospace industries or specific architectural designs. 5. Light H-beams are characterized by their lightweight design and find primary use in weight-sensitive applications like the automotive industry or lightweight structures. They offer a high strength-to-weight ratio and are available in various sizes. 6. Stainless steel H-beams are crafted from stainless steel, providing superior corrosion resistance and durability. They are commonly used in environments prone to moisture or chemical exposure, such as coastal areas or chemical processing plants. It is worth noting that the availability of these steel H-beam types may vary depending on the supplier or manufacturer. Therefore, it is advisable to consult a steel supplier or structural engineer to determine the most suitable H-beam type for your specific application.

- Q: Can steel H-beams be used for supporting modular building systems?

- Yes, steel H-beams can be used for supporting modular building systems. They provide excellent structural support and can be easily integrated into the modular construction process.

- Q: Can steel H-beams be used for industrial buildings?

- Yes, steel H-beams can be used for industrial buildings. Steel H-beams, also known as I-beams, are commonly used in the construction industry for their excellent structural properties. They are designed to withstand heavy loads and provide support for large spans, making them ideal for industrial buildings that require a strong and durable framework. Steel H-beams offer high strength-to-weight ratio, which means they can support heavy equipment and machinery without compromising the structural integrity of the building. Additionally, their versatility allows for various architectural designs and flexibility in accommodating different building layouts. Overall, steel H-beams are a popular choice for industrial buildings due to their strength, durability, and structural efficiency.

- Q: In actual steel structure engineering, why use H steel in large number, but seldom use I-beam? What's the difference between the two?

- I-beam is a hot rolling molding, and its advantage is low price, easy processing, if made of steel column beam, two end welding plate will become. However, H steel needs to be welded with web plate and wing plate, and a great deal of welding and welding variant process have been added. I finished length (i.e. the length of 12 meters), and H steel for processing factory in accordance with the design drawings for the exact dimensions of cutting, welding and straightening type to complete multiple steps, so the steel price is low.Also has section size waste little, use design margin of I-beam, but instead of using H steel, low cost, cost saving. But there are too few examples of this kind of engineering, and this is not a common design idea.

- Q: Can Steel H-Beams be used in retail or commercial building construction?

- Yes, Steel H-Beams can be used in retail or commercial building construction. These beams are commonly used in large-scale construction projects due to their high strength and load-bearing capacity. They provide structural support and stability, making them suitable for constructing large commercial and retail buildings.

- Q: Are steel H-beams resistant to fire?

- Yes, steel H-beams are highly resistant to fire. Due to their high melting point and excellent structural integrity, steel H-beams can withstand high temperatures and maintain their strength even during a fire. This makes them a popular choice for structural support in buildings and other fire-prone environments.

- Q: What are the limitations of steel H-beams?

- Steel H-beams come with a number of limitations. To start with, they are relatively expensive compared to materials like wood or concrete, which can be a hindrance for smaller construction projects or those with budget constraints. Furthermore, due to their weight, steel H-beams require specialized equipment for transportation and installation. This can complicate and increase the cost of a construction project, especially if the site is difficult to access. Another drawback is their vulnerability to corrosion, particularly in environments with high humidity or exposure to saltwater. This corrosion can weaken the beams over time, posing safety risks and necessitating maintenance. Moreover, steel H-beams have limited design flexibility. They are typically rigid and straight, making it more difficult to incorporate intricate architectural or structural designs. Lastly, steel H-beams have limited fire resistance. Since steel conducts heat well, in the event of a fire, the H-beams can rapidly transfer heat throughout the structure, potentially compromising its stability. To mitigate this limitation, fire protection measures such as fireproof coatings or additional fire-resistant materials may be required. In conclusion, while steel H-beams offer advantages in terms of strength and durability, their drawbacks including cost, weight, susceptibility to corrosion, design limitations, and fire resistance should be carefully considered when choosing a building material for a construction project.

Send your message to us

Steel H-Beam for Construction with High Quality and Competitive Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords