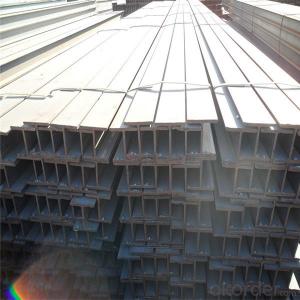

Wide Flange H Steel Beam Sizes Good Price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 120000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

OKorder is offering H BEAM at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

We can provide qualify goods,competitive price and speedy delivery.

Products Description

H Type Steel Size and Theoretical Weight | |||||

Size | Theoretical Weight | Size | Theoretical Weight | Size | Theoretical Weight |

|

|

|

|

|

|

(mm) | (kg/m) | (mm) | (kg/m) | (mm) | (kg/m) |

100*50*5*7 | 9.3 | 250*125*6*9 | 29 | 446*199*8*12 | 65.1 |

100*100*6*8 | 16.9 | 250*250*9*14 | 71.8 | 450*200*9*14 | 74.9 |

125*60*6*8 | 13.1 | 294*200*8*12 | 55.8 | 482*300*11*15 | 110.8 |

125*125*6.5*9 | 23.6 | 298*149*5.5*8 | 32 | 488*300*11*18 | 124.9 |

148*100*6*9 | 31.1 | 340*250*9*14 | 36.7 | 496*199*9*14 | 77.9 |

150*75*5*7 | 14 | 300*150*6.5*9 | 93 | 500*200*10*16 | 88.1 |

150*150*7*10 | 20.7 | 300*300*10*15 | 78.1 | 582*300*12*17 | 132.8 |

175*90*5*8 | 18 | 346*174*6*9 | 41.2 | 588*300*12*20 | 147 |

175*175*7.5*11 | 40.4 | 350*175*7*11 | 49.4 | 596*199*10*15 | 92.4 |

194*150*6*9 | 29.9 | 350*350*12*19 | 134.9 | 600*200*11*17 | 103.4 |

198*99*4.5*7 | 17.8 | 390*300*10*16 | 104.6 | 700*300*13*24 | 181.8 |

200*100*5.5*8 | 20.9 | 396*199*7*11 | 56.1 | 800*300*14*26 | 206.8 |

200*200*8*12 | 49.9 | 400*200*8*13 | 65.4 | 900*300*16*28 | 240.1 |

244*175*7*11 | 43.6 | 400*400*13*21 | 171.7 |

|

|

248*124*5*8 | 25.1 | 440*300*11*18 | 120.8 |

|

|

Length=6------12meters | |||||

Packaging & Delivery

Packaging Details: | Packed with waterproof paper and steel banding. |

Delivery Detail: | 15-25 |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: What are the common factors that affect the cost of steel H-beams?

- The common factors that affect the cost of steel H-beams include the price of raw materials such as iron ore and scrap metal, the production and manufacturing processes involved, market demand and supply dynamics, transportation and logistics costs, as well as any additional tariffs or taxes imposed on steel imports or exports.

- Q: How to declare the processed H steel? What is the rate of tax refund? Urgent urgent

- First of all, does your company have the right to import and export?! If you have, you can use your company to declare, if not, but also to find a business right to import and export enterprises to help you act as agent.

- Q: Are steel H-beams resistant to seismic activity?

- Yes, steel H-beams are generally considered to be resistant to seismic activity. Steel is a highly durable and strong material, which makes it well-suited for withstanding the forces generated during seismic events. H-beams, specifically, are designed to distribute the load evenly across their length, providing excellent structural support against both vertical and lateral movements. Moreover, steel H-beams are commonly used in earthquake-prone regions due to their superior seismic resistance. The inherent flexibility and elasticity of steel allow it to absorb and dissipate seismic energy, minimizing the damage caused by ground shaking. Additionally, steel H-beams are often interconnected with other structural elements, such as columns and braces, to form a seismic-resistant system that can effectively absorb and redirect seismic forces. However, it is important to note that the seismic resistance of steel H-beams can vary depending on various factors, such as the design, quality of construction, and adherence to building codes and regulations. Proper engineering and construction practices must be followed to ensure that steel H-beams are appropriately designed and installed to withstand the specific seismic conditions of a given area. Overall, when properly designed and constructed, steel H-beams offer excellent resistance to seismic activity and are widely used in earthquake-resistant building structures.

- Q: Are steel H-beams fire-resistant?

- Generally, Steel H-beams are regarded as fire-resistant due to their non-combustible nature and inability to ignite or facilitate fire propagation. Moreover, steel exhibits a high melting point, enhancing its resistance against heat and fire. However, it is essential to emphasize that although the steel beams themselves possess fire-resistant properties, other elements of the building or structure, including connections and adjacent materials, may lack such characteristics. Hence, it becomes imperative to take into account the comprehensive fire safety measures and adhere to building codes to guarantee the overall fire resistance of a structure.

- Q: What are the environmental impacts of using steel H-beams?

- The use of steel H-beams in construction and infrastructure projects has both positive and negative environmental impacts. On the positive side, steel H-beams are highly durable and have a long lifespan, which means they can be reused or recycled when no longer needed. This reduces the demand for new steel production and minimizes the extraction of raw materials, saving energy and reducing greenhouse gas emissions associated with steel manufacturing. However, the production of steel H-beams does have some negative environmental impacts. The manufacturing process involves the extraction of iron ore, which requires significant energy inputs and contributes to air and water pollution. Additionally, the production of steel from iron ore releases large amounts of carbon dioxide, a major greenhouse gas that contributes to climate change. The transportation of steel H-beams from the manufacturing facilities to construction sites also has environmental implications. Shipping and trucking of these heavy materials consume energy and contribute to air pollution, especially if long distances are involved. Furthermore, the construction process itself can have localized environmental impacts. Excavation and site preparation for installing steel H-beams can disrupt natural habitats, leading to habitat loss and fragmentation. Construction activities may also generate noise, dust, and other pollutants that can impact air and water quality and affect nearby ecosystems and communities. Overall, while the use of steel H-beams offers various benefits in terms of durability and recyclability, it is important to consider the environmental impacts associated with their production, transportation, and construction. To mitigate these impacts, sustainable practices such as using recycled steel, optimizing transportation routes, and implementing proper construction site management should be adopted.

- Q: What are the different fire protection methods for steel H-beams?

- Some of the different fire protection methods for steel H-beams include intumescent coatings, fire-resistant sprays or paints, and the use of fire-resistant boards or cladding. These methods are designed to delay the heating of the steel beams and prevent them from reaching critical temperatures, thereby preserving their structural integrity during a fire.

- Q: What are the different design considerations when using steel H-beams in architectural projects?

- When incorporating steel H-beams into architectural projects, it is vital to take several design factors into account. These factors encompass the following: 1. Ensuring Structural Stability: The primary purpose of using steel H-beams is their ability to bear heavy loads. Therefore, it is crucial to analyze the load distribution, deflection, and stress on the beams to guarantee their structural stability and their ability to safely support the intended loads. 2. Determining Span and Size: The load-bearing capacity of steel H-beams greatly depends on their span and size. To maintain structural integrity and prevent potential issues like excessive deflection or bending, architects must carefully select the appropriate beam size and span based on the requirements of the architectural project. 3. Establishing Connection Details: The connection details between steel H-beams and other structural elements are of utmost importance in creating a strong and dependable architectural design. By designing proper connections, architects can efficiently transfer loads, minimize stress concentrations, and facilitate construction and maintenance. 4. Addressing Fire Resistance: While steel H-beams possess inherent fire-resistant properties, certain architectural projects may necessitate additional fire protection measures to adhere to local building codes and safety regulations. These measures may involve the use of fire-resistant coatings or fireproofing materials to enhance the overall fire resistance of the structure. 5. Incorporating Aesthetics and Design Integration: Although primarily structural, steel H-beams can contribute to the overall visual appeal of an architectural project. By integrating the beams into the design in an aesthetically pleasing manner, architects can enhance the project's attractiveness. This could involve exposing the beams or incorporating them into architectural features to achieve an industrial or modern aesthetic. 6. Emphasizing Sustainability: In contemporary architectural projects, prioritizing sustainability is crucial. Steel is a highly sustainable material due to its recyclability and reusability. Therefore, architects must maximize the use of sustainable materials and minimize waste when incorporating steel H-beams into their designs. 7. Considering Cost Efficiency: Lastly, the cost efficiency of utilizing steel H-beams should be taken into consideration. Architects must evaluate the cost of materials, fabrication, transportation, and installation in relation to the project's budget and design requirements. By effectively planning and coordinating with structural engineers and contractors, cost efficiency can be optimized without compromising safety or quality. To summarize, design considerations for incorporating steel H-beams into architectural projects encompass structural stability, span and size determination, connection details, fire resistance, aesthetics and design integration, sustainability, and cost efficiency. By addressing these considerations, architects can ensure the successful integration of steel H-beams into their designs, resulting in safe, visually appealing, and sustainable structures.

- Q: Can steel H-beams be used in retail or shopping mall construction?

- Yes, steel H-beams can be used in retail or shopping mall construction. Steel H-beams are commonly used in construction due to their strength and durability. They provide structural support and can bear heavy loads, making them suitable for large commercial buildings like retail or shopping malls. Additionally, steel H-beams can be easily fabricated and installed, offering flexibility in design and construction. Their use in retail or shopping mall construction ensures a solid and stable framework, allowing for the construction of spacious, open-plan retail spaces and accommodating various architectural designs.

- Q: Can steel H-beams be used for retaining walls?

- Yes, steel H-beams can be used for retaining walls. They are commonly used in construction for their strength and durability, and their shape allows for efficient load-bearing capabilities. Steel H-beams provide stability and support, making them a suitable choice for retaining walls in various applications.

- Q: What are the design considerations for steel H-beams in high-rise buildings?

- When designing steel H-beams for high-rise buildings, several key considerations should be taken into account. These considerations include the following: 1. Load-bearing capacity: Steel H-beams are primarily used to carry and transfer the load of the building, so the design must ensure that the beams have sufficient load-bearing capacity to support the weight of the structure. This includes considering the dead load (weight of the building itself), live load (occupant and equipment loads), and wind load. 2. Structural stability: High-rise buildings are subjected to various forces, including wind, seismic activity, and temperature changes. The design of H-beams must ensure the structural stability of the building, incorporating proper bracing and connections to withstand these forces and prevent any potential collapse. 3. Fire resistance: In case of a fire, steel H-beams should be designed to maintain their structural integrity for a specified period, allowing occupants to evacuate safely. Fire-resistant coatings or fireproofing materials may be applied to enhance the fire resistance of the beams. 4. Deflection and vibration control: High-rise buildings are subject to deflection and vibrations caused by wind, earthquakes, and dynamic loads. The design must consider the maximum allowable deflection and vibration limits to ensure the comfort and safety of occupants. Measures such as increasing beam depth, adding stiffeners, or incorporating dampening devices can be considered to control deflection and vibration. 5. Fabrication and construction considerations: The design of steel H-beams should also take into account ease of fabrication and construction. The beams must be designed with standard sizes and lengths to facilitate efficient fabrication and erection processes. The connections between beams should also be designed to ensure ease of installation and maintain structural integrity. 6. Sustainability: Incorporating sustainable design principles is essential in modern high-rise buildings. The design of steel H-beams should aim to minimize material consumption and waste, optimize energy efficiency, and maximize the use of recycled materials. Overall, the design considerations for steel H-beams in high-rise buildings involve ensuring load-bearing capacity, structural stability, fire resistance, deflection and vibration control, ease of fabrication and construction, and sustainability. By carefully addressing these considerations, engineers can create safe, efficient, and sustainable high-rise buildings.

Send your message to us

Wide Flange H Steel Beam Sizes Good Price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 120000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords