Hot rolled Steel H-Beam

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

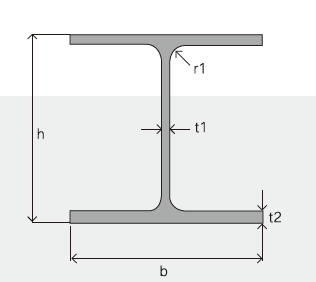

ecifications of Hot Rolled Steel H-beam

1. Standard: JIS 3192

2. Grade: SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

|

H x B (mm) |

T1 |

T2 |

JIS Weight (kg/m) |

GB Weight (kg/m) |

|

100*100 |

6 |

8 |

16.9 |

17.2 |

|

125*125 |

6.5 |

9 |

23.6 |

23.8 |

|

150*75 |

5 |

7 |

14 |

14.3 |

|

148*100 |

6 |

9 |

20.7 |

21.4 |

|

150*150 |

7 |

10 |

31.1 |

31.9 |

|

175*90 |

5 |

8 |

18 |

18.2 |

|

175*175 |

7.5 |

11 |

40.4 |

40.4 |

|

198*99 |

4.5 |

7 |

17.8 |

18.5 |

|

200*100 |

5.5 |

8 |

20.9 |

21.7 |

|

194*150 |

6 |

9 |

29.9 |

31.2 |

|

200*200 |

8 |

12 |

49.9 |

50.5 |

|

248*124 |

5 |

8 |

25.1 |

25.8 |

|

250*125 |

6 |

9 |

29 |

29.7 |

|

244*175 |

7 |

11 |

43.6 |

44.1 |

|

250*250 |

9 |

14 |

71.8 |

72.4 |

|

298*149 |

5.5 |

8 |

32 |

32.6 |

|

298*201 |

9 |

14 |

65.4 |

|

|

300*150 |

6.5 |

9 |

36.7 |

37.3 |

|

294*200 |

8 |

12 |

55.8 |

57.3 |

|

300*300 |

10 |

15 |

93 |

94.5 |

|

346*174 |

6 |

9 |

41.2 |

41.8 |

|

350*175 |

7 |

11 |

49.4 |

50 |

|

340*250 |

9 |

14 |

78.1 |

79.7 |

|

350*350 |

12 |

19 |

135 |

137 |

|

400*200 |

8 |

13 |

65.4 |

66 |

|

390*300 |

10 |

16 |

105 |

107 |

|

400*400 |

13 |

21 |

172 |

172 |

|

446*199 |

8 |

12 |

65.1 |

66.7 |

|

450*200 |

9 |

14 |

77.9 |

79.5 |

|

440*300 |

11 |

18 |

121 |

124 |

|

496*199 |

9 |

14 |

77.9 |

79.5 |

|

500*200 |

10 |

16 |

88.2 |

89.6 |

|

488*300 |

11 |

18 |

125 |

129 |

|

596*199 |

10 |

15 |

92.5 |

95.1 |

|

600*200 |

11 |

17 |

103.4 |

106 |

|

588*300 |

12 |

20 |

147 |

151 |

|

700*300 |

13 |

24 |

182 |

185 |

|

800*300 |

14 |

26 |

207 |

210 |

|

900*300 |

16 |

28 |

240.1 |

243 |

Usage & Applications of Hot Rolled Steel H-beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of Hot Rolled Steel H-beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Steel H-beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel H-beams be used for schools?

- Yes, steel H-beams can be used for schools. They are commonly used in the construction of school buildings due to their durability, strength, and ability to support heavy loads. Steel H-beams provide structural stability and reliability, making them a suitable choice for school construction projects.

- Q: What are the applications of steel H-beams?

- Steel H-beams possess structural integrity and versatility, making them highly applicable in a range of industries. Some common uses of steel H-beams include: 1. Construction industry: Steel H-beams are extensively employed in constructing buildings, bridges, and other structures due to their ability to provide robust support and stability for large and complex constructions. 2. Industrial buildings: Steel H-beams find wide usage in constructing industrial buildings and warehouses. Their capacity to bear heavy loads and resist bending makes them suitable for supporting heavy machinery and equipment. 3. Infrastructure projects: Steel H-beams are frequently utilized in infrastructure projects like highways, railways, and airports. They play a crucial role in constructing overpasses, underpasses, and other structures that require sturdy and enduring support. 4. Shipbuilding: Steel H-beams are employed in constructing ships and offshore structures. Their high tensile strength and resistance to corrosion make them ideal for marine applications. 5. Automotive industry: Steel H-beams are used in manufacturing automotive frames, chassis, and other structural components as they provide the necessary strength and rigidity to withstand vehicle stresses. 6. Mezzanine floors: Steel H-beams are commonly employed in constructing mezzanine floors in commercial and industrial buildings. They offer a cost-effective solution for creating additional floor space, enabling increased storage or office areas. 7. Support structures: Steel H-beams are commonly found in constructing support structures such as columns, trusses, and supports for roofs and canopies. These beams ensure stability and strength, facilitating the safe installation of various structures. 8. Civil engineering projects: Steel H-beams find applications in various civil engineering projects like retaining walls, flood barriers, and water treatment plants. Their durability and load-bearing capacity make them suitable for withstanding harsh environmental conditions. Overall, steel H-beams have diverse and widespread applications across various industries. Their strength, durability, and versatility make them an indispensable component in construction and engineering projects.

- Q: Are steel H-beams suitable for use in the construction of entertainment venues or stadiums?

- Yes, steel H-beams are suitable for use in the construction of entertainment venues or stadiums. Steel H-beams are commonly used in construction due to their strength, durability, and versatility. They provide excellent structural support and can withstand heavy loads, making them ideal for large-scale projects such as stadiums or entertainment venues. Steel H-beams offer several advantages for these types of constructions. Firstly, they have a high load-carrying capacity, allowing them to support the weight of large crowds, seating structures, and equipment. Additionally, their long spans and ability to resist bending make them suitable for creating large open spaces, such as sports arenas or concert halls. Moreover, steel H-beams have a high resistance to fire, which is crucial for ensuring the safety of occupants in entertainment venues. They can withstand high temperatures and provide a considerable amount of time for evacuation in case of a fire incident. This fire-resistant characteristic of steel H-beams makes them a reliable choice for venues where a large number of people gather. Furthermore, steel H-beams can be fabricated and pre-engineered off-site, allowing for faster construction and reduced costs. They can be easily transported and assembled, thereby expediting the construction process and minimizing disruption to surrounding areas. Lastly, steel H-beams have a long lifespan and require minimal maintenance. They are resistant to corrosion and deterioration, ensuring the longevity of the structures they support. In conclusion, steel H-beams are highly suitable for use in the construction of entertainment venues or stadiums due to their strength, durability, versatility, fire resistance, and cost-effectiveness. They offer the necessary structural support and safety features required for these types of large-scale projects, making them a preferred choice for architects and engineers in the industry.

- Q: Can steel H-beams be used in marine applications?

- Indeed, marine applications can certainly make use of steel H-beams. The construction industry frequently employs steel H-beams due to their impressive strength, durability, and versatility. These beams are engineered to provide structural support, enabling them to withstand substantial loads and forces. Consequently, in marine applications where structures face harsh circumstances like saltwater, corrosion, and powerful wave forces, steel H-beams can prove to be an excellent option. Nonetheless, it remains vital to carefully consider the specific requirements of the marine application. This includes evaluating the necessary level of corrosion resistance and selecting the appropriate grade of steel and protective coatings. By doing so, one can ensure prolonged performance and durability in marine environments.

- Q: Are steel H-beams resistant to sound or noise transmission?

- Steel H-beams are not inherently resistant to sound or noise transmission. However, they can be effective in reducing noise transmission if they are properly insulated or treated with soundproofing materials. Steel, being a dense material, has the potential to transmit sound waves easily. Therefore, additional measures need to be taken to minimize noise transmission through steel H-beams. This can be achieved by adding insulation materials such as rubber, foam, or other sound-absorbing materials to the beams. These materials help to absorb and dampen sound vibrations, reducing the amount of noise that passes through the beams. Additionally, proper construction techniques and design considerations, such as creating double walls or using resilient channels, can also help to mitigate sound transmission through steel H-beams. Ultimately, the effectiveness of steel H-beams in resisting sound or noise transmission depends on the specific construction methods and materials used in conjunction with the beams.

- Q: Are steel H-beams vulnerable to termites or pests?

- No, steel H-beams are not vulnerable to termites or pests. Unlike wood, steel does not provide a food source for termites, and it is not susceptible to damage caused by pests. Steel H-beams are made from a strong and durable material that is resistant to infestations and can withstand various environmental conditions. Therefore, they are a reliable choice for structural support in buildings where termite or pest damage is a concern.

- Q: How do steel H-beams perform in terms of noise reduction?

- Steel H-beams are primarily used for structural support rather than noise reduction. While they may provide some minimal noise dampening due to their density and mass, they are not specifically designed or effective in reducing noise levels.

- Q: What are the different design codes and standards for steel H-beams?

- Some of the different design codes and standards for steel H-beams include the American Institute of Steel Construction (AISC) 360, Eurocode 3, British Standards (BS) 5950, and the Canadian Standards Association (CSA) S16. These codes and standards provide guidelines and specifications for the design, fabrication, and construction of steel H-beams, ensuring structural integrity and safety.

- Q: Are steel H-beams suitable for structures with dynamic loads?

- Yes, steel H-beams are suitable for structures with dynamic loads. H-beams, also known as I-beams, are commonly used in construction due to their high strength-to-weight ratio, which makes them ideal for supporting heavy loads. The shape of an H-beam provides excellent resistance to bending, making it well-suited for structures that experience dynamic loads, such as bridges, cranes, and high-rise buildings. Steel H-beams possess superior structural integrity and can withstand the forces generated by dynamic loads, including vibrations, impacts, and cyclic loading. They are designed to distribute the load evenly along their length, minimizing stress concentrations and preventing deformation or failure. Moreover, steel is a durable material that exhibits excellent fatigue resistance, allowing H-beams to withstand repeated loading and unloading without compromising their mechanical properties. This makes them highly suitable for structures that experience varying or dynamic loads over time. Additionally, steel H-beams can be customized to meet specific structural requirements, such as length, size, and strength, making them versatile for a wide range of applications. They can be fabricated and connected to form complex structural systems that can efficiently handle dynamic loads. Overall, steel H-beams are a reliable and widely used choice in structural engineering for buildings and infrastructure that are subjected to dynamic loads.

- Q: Can steel H-beams be used for industrial warehouses?

- Yes, steel H-beams are commonly used for constructing industrial warehouses due to their structural strength, durability, and ability to support heavy loads.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 230 Million |

| Main Markets | Mid East; Southeast Asia; Korea |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 500,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Hot rolled Steel H-Beam

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords