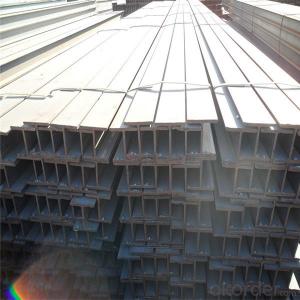

H Steel Beam from China at Good Price and Qaulity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

Place of Origin: | Tianjin, China (Mainland) | Grade: | Q235B | Technique: | High Frequency |

Application: | Building construction,Bridge construction etc. | Length: | 6.0meters,9meters,12meters | Standard: | ASTM |

Flange Width: | 100-750mm | Flange Thickness: | 3.0-10.0mm | Web Width: | 50-250mm |

Web Thickness: | 2.3-8.0mm | Brand Name: | Liye |

We can provide qualify goods,competitive price and speedy delivery.

Products Description

Description | High Frenquency Thin-walled H Beam | |

Product Name | H Beam | |

Specification | Height:75-500mm Width:50-250mm | |

Standard | GB700-1998,GB/T1591-1994 | |

Material | Q235B,Q345B | |

Application | a. Bridge and post structures in industry and civil use of steel construction. | |

Certificates | ISO,SGS,BV,TUV,Lloyd | |

MOQ | 20 tons or according to customers’ requirement. | |

Port of Delivery | Tianjin Port of China | |

Remarks | We can provide qualify goods,competitive price and speedy delivery |

Packaging & Delivery

Packaging Details: | Packed with waterproof paper and steel banding. |

Delivery Detail: | 15-25 |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: How do steel H-beams compare to wooden beams in terms of cost and performance?

- Steel H-beams and wooden beams differ significantly in terms of cost and performance. In terms of cost, steel H-beams tend to be more expensive than wooden beams. The cost of steel is generally higher than wood, and the fabrication and installation of steel H-beams can also be more labor-intensive and time-consuming. Additionally, steel H-beams often require specialized equipment and expertise, further adding to the overall cost. However, when it comes to performance, steel H-beams have several advantages over wooden beams. Firstly, steel is much stronger and more durable than wood. Steel H-beams can withstand higher loads and have a higher resistance to bending and warping, making them ideal for supporting heavy structures or spanning long distances. Wooden beams, on the other hand, may require additional supports or reinforcement to achieve similar load-bearing capacities. Moreover, steel H-beams are fire-resistant, unlike wooden beams which are highly flammable. This fire-resistant property makes steel H-beams a safer option for construction in areas prone to fire hazards. Additionally, steel H-beams are less prone to insect infestations, rot, and decay, which are common issues with wooden beams. This durability translates into a longer lifespan and reduced maintenance costs for structures built with steel H-beams. In conclusion, while steel H-beams tend to be more expensive than wooden beams, they offer superior performance in terms of strength, durability, fire resistance, and low maintenance. Therefore, the choice between steel H-beams and wooden beams ultimately depends on the specific requirements of the project, budget constraints, and the desired lifespan of the structure.

- Q: Are steel H-beams suitable for convention halls?

- Yes, steel H-beams are commonly used in the construction of convention halls due to their strength and versatility. H-beams provide excellent load-bearing capabilities, allowing for larger and more open spaces within convention halls. Their structural stability makes them ideal for supporting the weight of heavy equipment, lighting rigs, and other installations required in convention halls. Additionally, steel H-beams can be easily fabricated and installed, making them a practical choice for large-scale projects. Overall, steel H-beams are a reliable and suitable option for constructing convention halls.

- Q: H steel compared with ordinary steel in the end what are the advantages and disadvantages?

- Easy to machine: easy to connect and install, easy to remove and reuse.

- Q: Can steel H-beams be used in high-rise buildings?

- Yes, steel H-beams can be used in high-rise buildings. Steel H-beams are commonly used as structural elements in high-rise construction due to their high strength, durability, and ability to bear heavy loads. They provide excellent support and stability, making them a suitable choice for tall and large-scale structures.

- Q: Can steel H-beams be used in the construction of educational institutions or schools?

- Yes, steel H-beams can be used in the construction of educational institutions or schools. Steel H-beams are commonly used in the construction industry for their strength, durability, and ability to withstand heavy loads. They provide structural support for buildings, including educational institutions, ensuring stability and safety. Additionally, steel H-beams allow for flexible design options, making them suitable for constructing various types of educational facilities.

- Q: Are steel H-beams suitable for supporting mezzanine storage systems?

- Indeed, steel H-beams are a fitting choice for supporting mezzanine storage systems. Given their robustness and durability, steel H-beams are widely utilized in construction and industrial settings. They offer outstanding support for heavy loads and are engineered to endure considerable weight and pressure. Mezzanine storage systems, which necessitate sturdy and dependable support structures, demand the utmost safety and stability. Steel H-beams fulfill these prerequisites and are adept at effectively supporting mezzanine storage systems.

- Q: What are the fire resistance properties of steel H-beams?

- Steel H-beams have excellent fire resistance properties due to their high melting point and low thermal conductivity. They can withstand extreme heat for a prolonged period without losing their structural integrity, making them a reliable choice for fire-resistant construction.

- Q: What are the different tests conducted on Steel H-Beams to ensure quality and performance?

- There are several tests conducted on Steel H-Beams to ensure their quality and performance. These tests are crucial in determining the strength, durability, and suitability of the beams for various applications. Some of the common tests include: 1. Tensile Test: This test measures the tensile strength of the H-Beams by applying a controlled force until the beam fractures. It helps determine the maximum load the beam can withstand without breaking. 2. Bend Test: The bend test evaluates the beam's ability to withstand bending forces. It involves applying a force to the center of the beam until it reaches a specified deflection or fracture point. This test is essential to determine the beam's flexibility and resistance to deformation. 3. Impact Test: This test assesses the beam's resistance to sudden impact or shock loading. It involves striking the beam with a controlled impact force and measuring the energy absorbed during the impact. This test helps determine the beam's toughness and ability to absorb energy without fracture. 4. Fatigue Test: Fatigue testing involves subjecting the beam to repeated cyclic loading, simulating real-life conditions. The purpose is to evaluate the beam's resistance to fatigue failure over an extended period. This test is crucial to ensure the beam's long-term durability and performance under repetitive loading. 5. Chemical Composition Analysis: Analyzing the chemical composition of the steel used in H-Beams is vital to ensure it meets the required standards and specifications. This analysis ensures that the beam has the appropriate levels of specific elements, such as carbon, manganese, and sulfur, which directly impact its mechanical properties. 6. Ultrasonic Testing: This non-destructive test uses ultrasonic waves to detect any internal defects or flaws within the beam. It helps identify cracks, voids, or inclusions that may weaken the beam's structural integrity. Ultrasonic testing is particularly important in ensuring the overall quality and reliability of the beams. 7. Dimensional Inspection: Accurate dimensions are crucial for H-Beams, as they need to fit precisely in various structural applications. Dimensional inspection involves measuring the beam's length, width, height, and other critical dimensions to ensure they meet the specified tolerances. This test ensures that the beams are manufactured within the required dimensional range. By conducting these tests, manufacturers can ensure that Steel H-Beams meet the necessary quality standards and performance requirements, providing reliable and safe structural elements for construction and other applications.

- Q: What are the different connection details for steel H-beams?

- Steel H-beams have different connection details available depending on the specific application and structural requirements. Some commonly used connection details include: 1. The most frequently used connection detail for steel H-beams is the welded connection. This involves welding the flanges and web of the H-beam to the supporting structure or other steel members. Welded connections provide a strong and rigid connection, ensuring proper load transfer between the beams and the supporting structure. 2. Another option is the bolted connection, which uses bolts to connect the flanges of the H-beams to the supporting structure or other steel members. Bolted connections offer ease of installation and flexibility in terms of disassembly and reassembly. They are suitable for applications where the connection needs to be adjustable or removable. 3. A moment connection is designed to transfer both axial and bending moments between two H-beams. This type of connection is commonly used in multi-story buildings and bridges, where the transfer of significant loads and moments is required. Moment connections typically involve a combination of welded and bolted connections to ensure proper load transfer and stability. 4. Shear connections are used to transfer shear forces between two H-beams. This type of connection is often used in structures where the shear force is the primary concern, such as in roof trusses or floor systems. Shear connections can be achieved through welding, bolting, or a combination of both. 5. Splice connections are used to join two or more steel H-beams together to create longer or larger structural members. Splice connections can be achieved through welding or bolting, depending on the specific application and design requirements. Splice connections are commonly used in long-span structures, such as bridges and roof trusses. It is important to consider various factors, including the structural design, load requirements, and the type of forces expected to act on the structure, when selecting the connection detail for steel H-beams. The choice should be made in accordance with relevant structural codes and standards to ensure the safety and performance of the structure.

- Q: Are steel H-beams resistant to corrosion?

- Steel H-beams generally exhibit resistance to corrosion. Steel, a highly durable and adaptable material, possesses the ability to withstand exposure to weather conditions and various environmental factors. However, the degree of corrosion resistance may vary depending on the specific steel type utilized and the presence of protective coatings. When it comes to H-beams crafted from carbon steel, their susceptibility to corrosion increases, particularly in humid or corrosive surroundings. To bolster their resistance against corrosion, H-beams can undergo processes like galvanization or application of protective layers such as paint or epoxy. These coatings function as a barrier, effectively hindering moisture and other corrosive elements from reaching the steel surface. Consistent maintenance and proper care are also vital in preserving the corrosion resistance of steel H-beams over time.

Send your message to us

H Steel Beam from China at Good Price and Qaulity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords