High Quality Structural Steel H-Beam for Construction, Competitive Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specifications of High Quality Structural Steel H-Beam for Construction

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

SIZE(mm) | DIMENSION(kg/m) |

100*100 | 16.9 |

125*125 | 23.6 |

150*75 | 14 |

150*150 | 31.1 |

148*100 | 20.7 |

198*99 | 17.8 |

200*100 | 20.9 |

248*124 | 25.1 |

250*125 | 29 |

Usage & Applications ofHigh Quality Structural Steel H-Beam for Construction

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

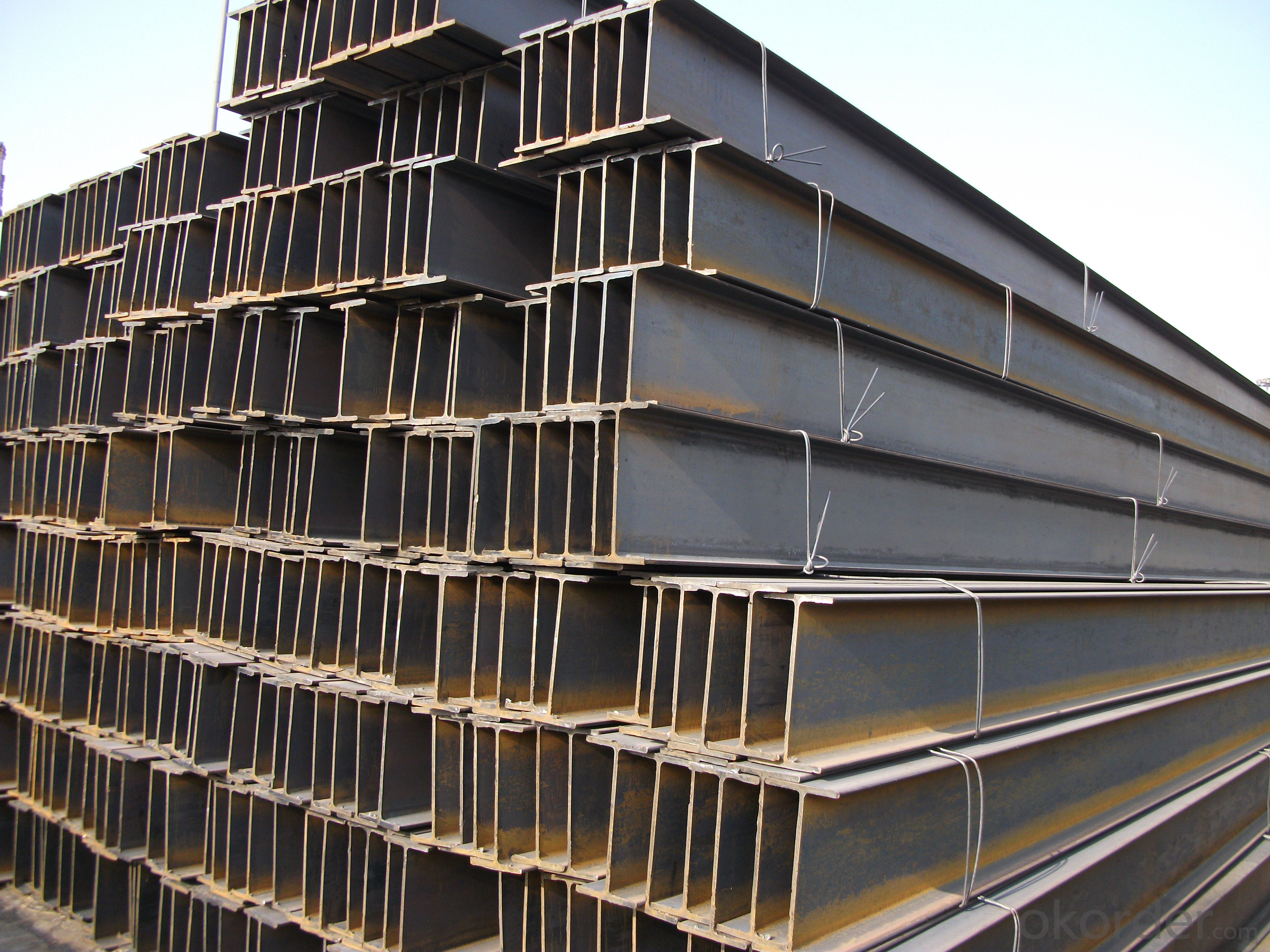

Packaging & Delivery of High Quality Structural Steel H-Beam for Construction

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of High Quality Structural Steel H-Beam for Construction

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Images

- Q: Can steel H-beams be used in curved structures?

- Yes, steel H-beams can be used in curved structures. H-beams are versatile structural components that can be used in a variety of applications, including curved structures. They are commonly used in construction projects where curved or arched designs are desired, such as bridges, stadiums, and architectural structures. To create a curved structure using steel H-beams, the beams can be bent or curved to the desired shape. This can be done through various fabrication techniques, such as cold bending, hot bending, or rolling the beams. The ability to bend or curve steel H-beams allows for the creation of complex and aesthetically pleasing structures that can withstand the required loads and stresses. It is important to note that the process of bending or curving steel H-beams requires specialized knowledge, equipment, and expertise. Structural engineers, architects, and steel fabricators must work together to ensure that the curved structure meets the necessary design requirements and safety standards. Additionally, factors such as the type and grade of steel used, the bending radius, and the structural loads must be carefully considered during the design and fabrication process. In summary, steel H-beams can be used in curved structures by bending or curving them to the desired shape. With proper design and fabrication techniques, steel H-beams can provide structural support and stability in a wide range of curved architectural and construction projects.

- Q: Can steel H-beams be used for industrial structures?

- Certainly, steel H-beams have proven to be a valuable option for industrial structures. In practice, they are widely utilized in the construction of a variety of industrial buildings and structures. These H-beams, which are also referred to as I-beams or universal beams, are specifically engineered to bear heavy loads and offer structural reinforcement. With a high strength-to-weight ratio, they are particularly well-suited for industrial applications where strength, durability, and stability are crucial. Warehouses, factories, power plants, and other industrial facilities frequently rely on steel H-beams to establish robust and dependable structures. Depending on the specific design requirements, these beams can be employed as columns, beams, or trusses. The adaptability of H-beams allows for diverse configurations and layouts, making them exceptionally suitable for a broad range of industrial construction projects. Moreover, steel H-beams provide numerous advantages over alternative construction materials. They possess fire-resistant, termite-resistant, and corrosion-resistant properties, ensuring the durability and longevity of the industrial structure. Additionally, steel is an environmentally sustainable and eco-friendly material as it can be recycled and reused, effectively reducing the environmental impact of the construction project. In conclusion, steel H-beams continue to be a favored choice for industrial structures due to their unparalleled strength, durability, and versatility. They offer the essential structural support and stability required for demanding industrial applications, making them an outstanding option for industrial construction projects.

- Q: Are there any environmental benefits to using Steel H-Beams?

- There are numerous environmental advantages associated with the utilization of steel H-beams in construction projects. To begin with, steel possesses exceptional durability and longevity, resulting in structures built with H-beams having a lengthier lifespan in comparison to alternative materials. Consequently, this diminishes the necessity for frequent maintenance, repairs, and replacements, thereby decreasing waste production and resource consumption. Furthermore, steel is an exceedingly recyclable material. At the conclusion of their lifecycle, H-beams can be conveniently disassembled and recycled, thereby reducing the requirement for new steel production. Moreover, recycling steel necessitates less energy and emits fewer greenhouse gases when compared to the production of new steel from raw materials, leading to a considerable reduction in carbon emissions. Moreover, steel H-beams exhibit a superior strength-to-weight ratio, allowing for the construction of lighter structures. Consequently, this reduces the overall weight of the building, resulting in reduced transportation and logistics costs. Additionally, it minimizes the amount of foundation material required, thereby mitigating the environmental impact of excavation and reducing the consumption of natural resources. Furthermore, steel is resistant to pests, like termites, and does not undergo rot or decay. This eliminates the need for chemical treatments that can prove harmful to the environment. By utilizing steel H-beams, builders can avoid the use of pesticides and preservatives, thereby promoting a healthier and more sustainable construction process. In conclusion, the utilization of steel H-beams in construction projects provides numerous environmental benefits. It increases the longevity of structures, encourages recycling and diminishes the demand for new steel production, reduces transportation and logistics costs, and eliminates the necessity for chemical treatments. These factors collectively contribute to a more sustainable and eco-friendly approach to construction.

- Q: Are steel H-beams suitable for structures with high ceilings?

- Yes, steel H-beams are suitable for structures with high ceilings.

- Q: How do you calculate the plastic moment capacity of steel H-beams?

- The plastic moment capacity of a steel H-beam can be calculated using the formula M = Fy * Z, where M is the plastic moment capacity, Fy is the yield strength of the steel, and Z is the plastic section modulus of the H-beam. The plastic section modulus can be determined by dividing the moment of inertia of the beam about its neutral axis by the distance from the neutral axis to the extreme fiber.

- Q: How do steel H-beams contribute to architectural design?

- Architectural design relies heavily on steel H-beams due to the multitude of advantages they offer. Foremost, H-beams are renowned for their strength and durability. They possess a high load-bearing capacity, allowing architects to design buildings with larger open spaces and longer spans, eliminating the need for additional supporting columns or walls. This grants architects the freedom to create flexible and versatile spaces, particularly advantageous in commercial and industrial settings where expansive areas are often required. Furthermore, steel H-beams exhibit exceptional resistance against various forces such as wind, earthquakes, and vibrations. Their sturdy nature enables them to evenly absorb and distribute these forces throughout the structure, ensuring the building's safety and stability. This becomes especially crucial in areas prone to natural disasters or regions with high wind speeds. Apart from their structural benefits, H-beams also contribute significantly to the aesthetic appeal of architectural designs. Their sleek and minimalist design allows for clean lines and a modern look, making them a popular choice among architects and designers. Moreover, the versatility of H-beams permits creative and innovative designs, enabling architects to craft unique and visually striking structures. Additionally, steel H-beams come in various sizes and shapes, affording architects the flexibility to design structures of different scales and complexities. This versatility facilitates the realization of a wide range of architectural styles, from towering skyscrapers to cozy residential buildings. Moreover, H-beams boast high sustainability and environmental friendliness. Steel is a recyclable material, and incorporating H-beams in construction helps reduce the demand for new steel production, thereby minimizing the building's carbon footprint. Additionally, steel structures are known for their long lifespan, requiring minimal maintenance and reducing the need for future renovations or demolitions. In conclusion, steel H-beams play a crucial role in architectural design, providing strength, durability, and aesthetic appeal. Their ability to support large open spaces, withstand external forces, and adapt to various design styles makes them an indispensable and versatile component in the construction industry.

- Q: What are the vibration damping properties of steel H-beams?

- Steel H-beams have excellent vibration damping properties due to their high stiffness and mass. The unique design of the H-beam, with a wide flange and a narrow web, provides increased resistance to bending and torsional forces, making it an ideal choice for structural applications where vibration control is important. The stiffness of steel H-beams helps to reduce the amplitude of vibrations and dampen their energy. The high modulus of elasticity of steel allows it to resist deformation under applied loads, thereby minimizing the transmission of vibrations. This property is particularly beneficial in structures such as bridges, skyscrapers, and industrial buildings, where vibrations can be generated by external sources like wind, earthquakes, or machinery. Moreover, the mass of steel H-beams contributes to their vibration damping capabilities. The higher the mass, the greater the ability to absorb and dissipate the energy of vibrations. Steel is a dense material, making H-beams relatively heavy, which helps to reduce the resonant frequency of the structure. Lower resonant frequencies are desirable as they prevent the amplification of vibrations and limit their propagation. Additionally, the inherent damping properties of steel also contribute to vibration control. Steel exhibits a certain level of internal friction, known as structural damping, which converts vibrational energy into heat. This dissipation of energy effectively reduces the amplitude and duration of vibrations, resulting in improved vibration damping performance. In conclusion, steel H-beams possess excellent vibration damping properties due to their high stiffness, mass, and inherent damping characteristics. Their ability to resist deformation, absorb energy, and dissipate vibrations makes them an excellent choice for structural applications requiring vibration control and stability.

- Q: What are the factors to consider when designing with steel H-beams?

- Several important factors need to be taken into account when designing with steel H-beams. Firstly, a thorough assessment of the load-bearing capacity of the H-beams is essential. This involves calculating the maximum expected loads, such as the weight of the structure, additional loads it will bear (e.g., people or machinery), and any external forces it may encounter (e.g., wind or seismic activity). The dimensions and material properties of the H-beams must be chosen carefully to ensure they can support these loads without deforming or failing. Another crucial factor to consider is the span or distance between supports. The longer the span, the larger and stronger the H-beams will need to be in order to prevent excessive deflection. It is vital to select the appropriate beam size and spacing to guarantee structural integrity and avoid any potential sagging or buckling. The connection details between the H-beams and other structural members should also be given careful consideration. These connections must be designed to effectively transfer the loads and maintain the overall stability of the structure. Factors such as the type of connection (welded, bolted, or a combination), the size and number of bolts or welds, and the connection's resistance to shear and moment forces should all be evaluated. Additionally, when designing with steel H-beams, it is important to take into account the potential for corrosion and environmental factors. Steel is susceptible to corrosion, so if the structure will be exposed to moisture, chemicals, or other corrosive elements, appropriate protective measures like coating or galvanizing may be necessary to prolong the lifespan of the H-beams. Lastly, the cost and availability of the steel H-beams should also be factored in. Different sizes and grades of steel will have different costs and levels of availability, so it is vital to strike a balance between the desired structural performance and practical considerations. In summary, when designing with steel H-beams, it is crucial to assess the load-bearing capacity, span, connection details, corrosion resistance, and cost factors carefully in order to ensure a safe and structurally sound design.

- Q: What are the typical uses of steel H-beams in construction projects?

- Steel H-beams are commonly used in construction projects for a variety of purposes. One of the typical uses of steel H-beams is for structural support in buildings and bridges. These beams are designed to withstand heavy loads and provide stability to the structure. In building construction, steel H-beams are used as columns and beams to support the weight of the building and distribute the load evenly. They are commonly used in high-rise buildings, industrial structures, and warehouses. H-beams are also used in the construction of bridges, where they provide the necessary strength and stability to support the weight of the bridge and the traffic passing over it. Another typical use of steel H-beams is in the construction of mezzanine floors. Mezzanine floors are intermediate floors that are built within a building to create additional usable space. H-beams are used as the primary support structure for these floors, providing the necessary strength and stability. Steel H-beams are also commonly used in the construction of platforms, walkways, and staircases. They provide a sturdy and reliable structure for these elements, ensuring the safety of those using them. Overall, steel H-beams are essential components in construction projects, providing structural support, stability, and strength. Their versatility and durability make them a popular choice in various construction applications.

- Q: Are steel H-beams susceptible to rust?

- Yes, steel H-beams are susceptible to rust. Steel is primarily made from iron, and iron is highly prone to corrosion when exposed to moisture and oxygen. Over time, if the H-beams are not properly protected or maintained, they can develop rust. To prevent rust formation, it is essential to apply protective coatings such as paint or galvanization, which act as a barrier between the steel and the surrounding environment. Additionally, regular inspections and maintenance can help identify and address any signs of corrosion before it becomes a significant issue.

Send your message to us

High Quality Structural Steel H-Beam for Construction, Competitive Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords