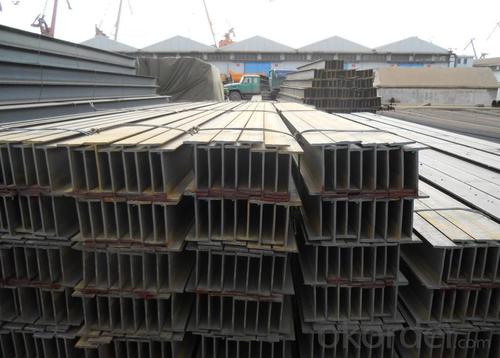

Prime Hot Rolled Mild Steel H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT/month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Prime Hot Rolled Mild Steel H Beam

1. Standard: EN10034-1993 / EN10025-2004,

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

SIZE(MM) | KG/M |

100*100 | 16.9 |

125*125 | 23.6 |

150*75 | 14 |

150*150 | 31.1 |

148*100 | 20.7 |

198*99 | 17.8 |

200*100 | 20.9 |

248*124 | 25.1 |

250*125 | 29 |

300*150 | 36.7 |

298*149 | 32 |

200*200 | 49.9 |

294*200 | 55.8 |

346*174 | 41.2 |

350*175 | 49.4 |

244*175 | 43.6 |

175*175 | 40.4 |

Usage & Applications of Prime Hot Rolled Mild Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Prime Hot Rolled Mild Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Prime Hot Rolled Mild Steel H Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel H-beams be used for supporting sports stadium roofs?

- Yes, steel H-beams can be used for supporting sports stadium roofs. H-beams are commonly used in construction due to their high strength and load-bearing capacity, making them suitable for supporting large structures like stadium roofs.

- Q: What are the applications of steel H-beams?

- Steel H-beams have a wide range of applications in the construction industry. They are commonly used as structural support beams in buildings, bridges, and infrastructure projects. H-beams provide excellent strength and load-bearing capabilities, making them ideal for withstanding heavy loads and providing structural stability. Additionally, they are used in the manufacturing of machinery, equipment, and vehicles, as well as for framing and support in various industrial applications.

- Q: What are the common factors that affect the cost of steel H-beams?

- There are several common factors that can affect the cost of steel H-beams. 1. Raw material costs: The cost of the raw materials used to manufacture steel H-beams, such as iron ore and coal, can have a significant impact on the overall cost. Fluctuations in the prices of these raw materials can directly affect the cost of production and consequently the selling price of the H-beams. 2. Manufacturing process: The manufacturing process of steel H-beams involves various stages, including melting, casting, rolling, and heat treatment. The efficiency and complexity of these processes can impact the cost. Technological advancements, energy consumption, labor costs, and equipment maintenance expenses all play a role in determining the overall manufacturing cost. 3. Market demand and supply: The demand and supply dynamics of steel H-beams can influence their cost. If there is high demand and limited supply, the prices are likely to be higher. Conversely, if there is low demand and excess supply, prices may be lower. Market conditions, construction projects, and economic factors can all affect the demand and supply of steel H-beams. 4. Transport and logistics: The cost of transporting steel H-beams from the manufacturing facility to the customer's location can impact the final price. Factors such as distance, transportation mode, fuel prices, and handling charges can all contribute to the overall cost. Additionally, import duties, taxes, and tariffs imposed by different countries can also affect the cost of steel H-beams. 5. Quality and specifications: The quality and specifications of steel H-beams can influence their cost. Higher-quality materials, superior finishes, and precise dimensions might result in higher prices. Additionally, specific requirements such as custom sizes, lengths, or special coatings can increase the cost of production and, consequently, the selling price. 6. Competition and market conditions: The level of competition in the steel industry can influence the cost of H-beams. Intense competition among manufacturers can lead to price wars and lower prices. Economic factors, global trade policies, and market trends can also impact the cost of steel H-beams. It is important to note that these factors can vary based on geographic location, industry-specific requirements, and other external factors. Consequently, the cost of steel H-beams can fluctuate over time due to changes in any or all of these factors.

- Q: What are the different types of steel H-beam connections used in residential buildings?

- Residential buildings commonly utilize various types of steel H-beam connections to ensure stability and strength for the overall structure. Here are some examples: 1. Welded Connection: The most frequently used connection method in residential buildings involves directly welding the H-beam to the supporting structure, such as columns or beams. This technique employs high-strength welding techniques to provide excellent strength and rigidity, making it suitable for applications with heavy loads or high lateral forces. 2. Bolted Connection: Another option is to use high-strength bolts to connect the H-beam to the supporting structure. This method offers easy installation and allows for convenient disassembly or modification when necessary. Bolted connections are commonly employed in situations that require adjustability or removability of the H-beam, such as mezzanine floors or temporary structures. 3. Shear Plate Connection: This type of connection involves placing steel plates on both sides of the H-beam, which are then bolted together. By distributing the load from the beam to the supporting structure, shear plate connections provide excellent strength and stability. They are commonly utilized when the H-beam needs to withstand heavy loads or moments. 4. Clip Angle Connection: Clip angle connections utilize steel angles that are welded to both the H-beam and the supporting structure. These angles provide additional support and rigidity to the connection. Clip angle connections are often employed in situations where the H-beam needs to resist lateral loads or uplift forces. 5. Moment Connection: Moment connections are specifically designed to resist rotational forces or moments. These connections combine welding and bolting techniques to ensure a rigid and strong connection between the H-beam and the supporting structure. Moment connections are frequently used to support large cantilevered structures or heavy loads. It is worth noting that the selection of a specific type of steel H-beam connection for a residential building depends on various factors, including load requirements, architectural design, and recommendations from structural engineers.

- Q: What are the different welding methods for steel H-beams?

- There are several different welding methods that can be used for steel H-beams. 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW is a common method used for welding H-beams. It involves using a consumable electrode coated in flux, which creates a shield around the weld pool to protect it from contaminants and oxidation. This method is versatile and can be used for welding in various positions and environments. 2. Gas Metal Arc Welding (GMAW): Also known as MIG welding, GMAW uses a continuous solid wire electrode and a shielding gas. This method offers high deposition rates, good weld quality, and can be easily automated. It is commonly used for H-beam welding in fabrication shops. 3. Flux-Cored Arc Welding (FCAW): FCAW is similar to GMAW but uses a tubular electrode filled with flux instead of a solid wire. The flux provides shielding and also contains deoxidizers and other elements to enhance the weld quality. FCAW is known for its high deposition rates and can be used for both indoor and outdoor welding applications. 4. Submerged Arc Welding (SAW): SAW is a highly efficient method that involves feeding a continuous wire electrode into a weld joint while a granular flux is poured over it. The flux covers the weld and prevents atmospheric contamination. SAW is commonly used for heavy-duty applications, such as welding large steel H-beams. 5. Laser Beam Welding (LBW): LBW is a precise and high-energy welding method that uses a focused laser beam to create a weld. It is commonly used for thin steel H-beams and offers excellent control and minimal distortion. However, LBW requires specialized equipment and is typically used in industrial settings. These are just a few of the many welding methods available for steel H-beams. The choice of method depends on factors such as the thickness of the material, desired weld quality, production speed, and available equipment. It is important to select the appropriate welding method based on the specific requirements of the H-beam project.

- Q: What are the different types of steel H-beam profiles?

- Different purposes and applications call for various types of steel H-beam profiles. Let's explore some of the common ones: 1. The standard H-beam is widely used due to its wide flange and tapered web, which make it suitable for different structural applications. 2. The wide flange (W) beam offers enhanced stability and load-bearing capacity with its wider flange. It is commonly employed in construction projects that demand robust support beams. 3. The American standard beam (S), also known as S-beams, features a narrower flange and thinner web compared to standard H-beams. These are commonly utilized in smaller-scale construction projects. 4. The European standard beam (HEA/HEB/HEM) adheres to European standards and has a wider flange than standard H-beams. It finds common application in construction projects across Europe. 5. The Japanese standard beam (JIS) conforms to Japanese industrial standards and is frequently used in construction projects in Japan. With its wide flange and thick web, it exhibits excellent load-bearing capabilities. 6. The light H-beam is lighter in weight compared to standard H-beams. It is commonly employed in weight-sensitive applications like lightweight construction or transportation. 7. Special profiles encompass H-beams with rounded corners or unique shapes. These profiles cater to specific requirements or architectural aesthetics. Ultimately, the choice of H-beam profile depends on factors such as load-bearing capacity, structural requirements, and adherence to regional standards.

- Q: Can steel H-beams be used in the construction of exhibition halls or convention centers?

- Yes, steel H-beams can be used in the construction of exhibition halls or convention centers. Steel H-beams are commonly used in construction due to their high strength and durability. They provide excellent structural support and can withstand heavy loads, making them suitable for large-scale buildings like exhibition halls and convention centers. The H-shape of these beams offers increased stability and resistance to bending, making them ideal for constructing wide-span structures. Additionally, steel H-beams can be easily fabricated and installed, saving time and cost during construction. Therefore, steel H-beams are a popular choice for the construction of exhibition halls or convention centers, providing a reliable and robust framework for these types of buildings.

- Q: What are the different protective coatings available for steel H-beams?

- There are several different protective coatings available for steel H-beams, including galvanizing, epoxy coatings, polyurethane coatings, and powder coatings. These coatings provide varying degrees of protection against corrosion, abrasion, and other forms of damage, depending on the specific requirements of the application.

- Q: How do steel H-beams connect to other structural elements?

- Depending on the particular design and engineering needs of a project, Steel H-beams can be connected to other structural elements in various ways. One common approach involves the use of bolts or welds. When joining H-beams to other steel components like columns or beams, it is common to fasten them together using high-strength bolts. These bolts are inserted through pre-drilled holes in the flanges (the horizontal top and bottom sections) of the H-beam and then tightened with nuts. This establishes a secure and rigid connection between the H-beam and the other structural elements. Another method employed to connect steel H-beams to other structural elements is welding. In this case, the flanges of the H-beam are welded to the adjacent components, ensuring a robust and permanent connection. Welding is often favored when there is a need for high load-bearing capacity and structural integrity. Apart from bolts and welds, other connection methods such as connectors or brackets can also be utilized depending on the specific project requirements. These connectors or brackets are often designed to provide additional strength and stability to the connection between the H-beam and other structural elements. It is important to emphasize that the choice of connection method for steel H-beams is contingent upon various factors, including load-bearing capacity, structural design, and safety regulations. Structural engineers and designers meticulously consider these factors to ensure that the connection is strong, secure, and capable of withstanding the forces and loads imposed on the structure.

- Q: How do steel H-beams perform in high wind conditions?

- Steel H-beams are highly durable and perform exceptionally well in high wind conditions. The unique design of H-beams provides them with superior strength and stability, making them ideal for withstanding strong winds. The horizontal flanges of the H-beams distribute the wind load evenly, while the vertical web resists any twisting or bending forces caused by the wind. This structural integrity ensures that the H-beams remain stable and secure even during extreme wind events. Moreover, steel H-beams have a high strength-to-weight ratio, which means they can withstand significant wind pressures without adding excessive weight to the overall structure. This advantage allows for more flexible and efficient designs, making steel H-beams a popular choice in construction projects located in areas prone to high wind conditions. Additionally, steel H-beams are highly resistant to corrosion, which further enhances their performance in high wind conditions. Unlike other building materials, such as wood or concrete, steel does not degrade or weaken when exposed to moisture or harsh weather conditions. This corrosion resistance ensures the long-term durability and structural integrity of steel H-beams, even in challenging environments. In summary, steel H-beams are designed to excel in high wind conditions. Their unique shape, strength, and resistance to corrosion make them capable of withstanding strong winds while providing stability and security to the overall structure. Therefore, steel H-beams are a reliable choice for buildings and structures in areas prone to high wind events.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 230 Million |

| Main Markets | Mid East; Southeast Asia; Korea |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 500,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Prime Hot Rolled Mild Steel H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT/month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords