wholesale H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

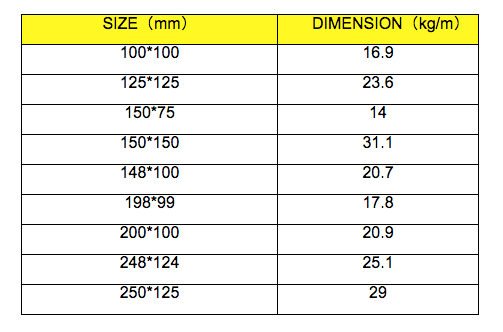

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Can steel H-beams be used in the construction of museums and art galleries?

- Yes, steel H-beams can definitely be used in the construction of museums and art galleries. Steel H-beams are known for their strength and durability, making them suitable for supporting heavy loads and withstanding structural stresses. These beams provide excellent structural support, allowing for large open spaces and flexible layouts within the museum or art gallery. Moreover, steel H-beams can be fabricated to various sizes and lengths, providing versatility in design and construction. Additionally, the sleek and modern aesthetic of steel beams can also complement the overall architectural style and design of the museum or art gallery. Overall, steel H-beams are a popular choice in the construction industry due to their strength, durability, and versatility, making them an ideal material for use in museums and art galleries.

- Q: Can steel H-beams be used for supporting pedestrian bridges?

- Yes, steel H-beams can be used for supporting pedestrian bridges. Steel H-beams are commonly used in construction due to their high strength and load-bearing capacity. They are designed to withstand heavy loads and provide structural support. The H-shape of the beam allows for a greater surface area to distribute weight, making them an ideal choice for supporting pedestrian bridges. Additionally, steel beams are durable, resistant to corrosion, and require minimal maintenance, which makes them suitable for long-term use in outdoor applications. Overall, steel H-beams are a reliable and commonly used option for supporting pedestrian bridges.

- Q: How do you calculate the maximum bending stress in steel H-beams?

- In order to determine the maximum bending stress in steel H-beams, several factors must be taken into account. Firstly, the maximum bending moment that the H-beam will experience needs to be determined. This can be achieved by analyzing the applied loads on the beam, including dead loads (the weight of the structure itself) and live loads (any additional weight placed on the beam). By calculating the reactions at the supports and summing the moments at any given section of the beam, the maximum bending moment can be established. Next, it is necessary to calculate the section modulus of the H-beam. The section modulus is a geometric property of the beam's cross-section, indicating its resistance to bending. This can be calculated by dividing the moment of inertia of the cross-section by the distance from the centroid of the cross-section to the extreme fiber. The moment of inertia can be found in standard engineering references or by using software programs. Finally, the maximum bending stress can be calculated utilizing the formula σ = M / S, where σ represents the maximum bending stress, M is the maximum bending moment, and S is the section modulus. This formula establishes the relationship between the applied moment and the stress induced in the beam. It is important to emphasize that accurate input data, including correct values for loads, beam dimensions, and material properties, are crucial for calculating the maximum bending stress in steel H-beams. Moreover, it is advisable to consult the applicable design code or standard for any specific requirements or factors that need to be considered.

- Q: Are steel H-beams suitable for structures with high ceilings?

- Yes, steel H-beams are suitable for structures with high ceilings. H-beams are commonly used in construction projects due to their strength and load-bearing capabilities. They are designed to support heavy loads and provide stability to the structure. The H-shape of the beams allows for efficient distribution of weight, making them ideal for structures with high ceilings where there may be increased vertical loads. Additionally, steel H-beams are durable and resistant to various environmental factors such as fire, moisture, and pests, making them a reliable choice for long-term structural integrity.

- Q: Can steel H-beams be used in the construction of railway infrastructure?

- Yes, steel H-beams can be used in the construction of railway infrastructure. These beams are commonly used as a structural element in various construction projects, including bridges, buildings, and railways. They offer high strength and durability, making them suitable for supporting heavy loads and withstanding the dynamic forces associated with railway operations.

- Q: Can Steel H-Beams be used in roof or ceiling construction?

- Yes, steel H-beams can be used in roof or ceiling construction. They are commonly used to provide structural support and stability to roofs and ceilings, especially in commercial and industrial buildings. Steel H-beams offer high strength and durability, making them suitable for handling heavy loads and spanning long distances. Additionally, their versatility allows for various design options and ease of installation.

- Q: Can the section steel butt joint in the end?

- Bolt connection also requires lining plate, pay attention to bolt size, quantity and spacing. To calculate whether thin-walled steel itself will be crushing, the solution is solder paste board, and bolt holes. The principle is that the strength of the butt joint is not weaker than that of other parts, and there is no greater stress.

- Q: How do steel H-beams perform in vibration-prone environments?

- Steel H-beams are known for their excellent performance in vibration-prone environments. The unique design of H-beams, with their wide flanges and vertical web, provides superior rigidity and strength, making them highly resistant to vibrations. This structural shape helps to distribute the load evenly, minimizing the effects of vibrations on the beam. By using steel as the material for H-beams, they offer exceptional durability and stability, which is crucial in environments where vibrations are common. Steel has a high modulus of elasticity, meaning it can withstand and absorb vibrations without undergoing significant deformation or damage. This property makes steel H-beams a reliable choice for structures exposed to dynamic loads, such as bridges, high-rise buildings, and industrial facilities. Furthermore, steel H-beams can be fabricated with additional measures to enhance their performance in vibration-prone environments. These measures include using thicker flanges, increasing the beam's depth, or incorporating damping materials. By taking these steps, the H-beams can further dampen vibrations and reduce their effect on the overall structure. In conclusion, steel H-beams are well-suited for vibration-prone environments due to their inherent strength, rigidity, and durability. Their unique design and properties enable them to withstand vibrations without compromising the structure's stability. When properly designed and executed, steel H-beams provide a reliable and efficient solution for structures that need to perform well in such challenging conditions.

- Q: What are the common fire protection measures for steel H-beams?

- Steel H-beams can be protected from fire through the use of various measures. One common method involves applying fire-resistant coatings directly onto the beams. These coatings are designed to endure high temperatures, effectively preventing the steel from reaching its critical temperature and thus maintaining its structural integrity. Another option is to use intumescent paints, which expand when exposed to heat. This expansion creates an insulating layer that slows down the transfer of heat to the steel beam, safeguarding it from the destructive effects of fire. Additionally, fire-resistant cladding can be installed around the steel H-beams. This cladding acts as an extra protective layer, insulating the steel from heat and flames. By implementing these measures, the structural stability of steel H-beams can be ensured during a fire, preventing any potential failure.

- Q: How do steel H-beams perform in areas with high humidity and moisture?

- Steel H-beams are well-suited for areas with high humidity and moisture due to their durability and resistance to corrosion. However, it is important to properly maintain and protect these beams in order to ensure their longevity. In environments with elevated levels of moisture, it is crucial to protect steel H-beams from corrosion. Moisture, especially when combined with oxygen and contaminants, can cause rust to form on the surface of the beams. This rust can compromise the structural integrity of the steel, potentially reducing its ability to bear loads. To prevent corrosion and maintain the performance of steel H-beams in these conditions, several measures can be taken. One common approach is to apply protective coatings, such as galvanization or painting. Galvanization involves coating the steel with a layer of zinc, which acts as a sacrificial barrier, protecting the underlying steel from corrosion. Painting with corrosion-resistant coatings can also provide a similar protective effect. In addition to protective coatings, it is important to install proper drainage and ventilation systems to minimize moisture accumulation around the H-beams. Regular inspections and maintenance are also crucial to promptly identify and address any signs of corrosion or damage. In conclusion, steel H-beams can be used in areas with high humidity and moisture, but it is necessary to take preventive measures to ensure their long-term performance and structural integrity. By implementing protective coatings, drainage systems, and regular maintenance, the risk of corrosion can be significantly reduced, allowing steel H-beams to effectively function in such environments.

Send your message to us

wholesale H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords