GB Standard Steel H Beam 388mm-400mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

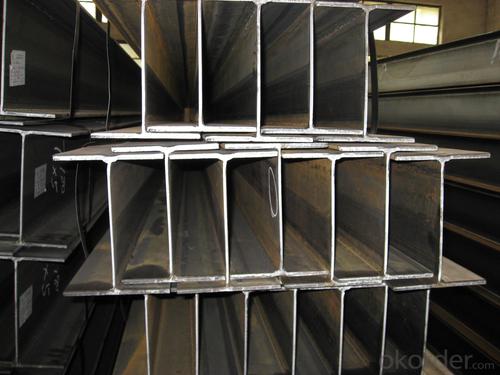

Specifications of GB Standard Steel H Beam 388mm-400mm with Good Quality For Sale:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 396*199*7.0 | 56.1 | 400*300*10.0 | 105 |

| 400*200*8.0 | 65.4 | 388*402*15.0 | 140 |

Usage & Applications of GB Standard Steel H Beam 388mm-400mm with Good Quality:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Production flow of GB Standard Steel H Beam 388mm-400mm with Good Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

Images of GB Standard Steel H Beam 388mm-400mm with Good Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What are the different types of connections used for steel H-beams in multi-story buildings?

- There are several types of connections commonly used for steel H-beams in multi-story buildings. Some of these include bolted connections, welded connections, and composite connections. Bolted connections involve using bolts and nuts to join the beams together, providing flexibility and ease of installation. Welded connections involve melting and fusing the beams together using heat, creating a strong and rigid connection. Composite connections combine both bolted and welded connections, utilizing the advantages of both methods to achieve optimal strength and performance. The choice of connection type depends on various factors, such as design requirements, structural loadings, and construction methods.

- Q: Can steel H-beams be used in hospital buildings?

- Yes, steel H-beams can be used in hospital buildings. They are commonly used in construction due to their strength, durability, and ability to support heavy loads. Steel H-beams provide structural integrity and are often used in critical areas such as columns and beams to ensure the stability and safety of the building.

- Q: How do steel H-beams perform under heavy loads or stresses?

- Steel H-beams are known for their excellent load-bearing capabilities and high resistance to heavy loads or stresses. Due to their structural design, H-beams distribute the load evenly along their length, allowing them to efficiently handle heavy loads without experiencing significant deformations or failures. Their sturdy construction and strong material properties make them an ideal choice for supporting large structures or carrying heavy loads in various applications.

- Q: Can steel H-beams be used in the construction of commercial buildings or offices?

- Yes, steel H-beams can be used in the construction of commercial buildings or offices. Steel H-beams are commonly used in the construction industry due to their strength, durability, and versatility. They provide excellent structural support, making them ideal for constructing large commercial buildings or office spaces. H-beams are designed to withstand heavy loads and provide stability, making them suitable for multi-story constructions. Additionally, steel H-beams can be easily fabricated and installed, saving time and labor costs during the construction process. Overall, steel H-beams are a popular choice for commercial building and office construction due to their structural integrity and efficiency.

- Q: How do steel H-beams contribute to sustainable transportation infrastructure?

- Steel H-beams contribute to sustainable transportation infrastructure in several ways: 1. Durability: Steel H-beams are extremely durable and can withstand heavy loads and harsh weather conditions. This means that they have a longer lifespan compared to other materials, reducing the need for frequent replacements. As a result, there is less material waste and energy consumption associated with the maintenance and repair of transportation infrastructure. 2. Cost-effectiveness: Steel H-beams are cost-effective due to their longevity and low maintenance requirements. By minimizing the need for repairs and replacements, they help save significant costs over the lifetime of a transportation infrastructure project. This allows for efficient allocation of resources, making it more sustainable in terms of budget management. 3. Recyclability: Steel is one of the most recycled materials in the world, and H-beams made from steel can be easily recycled at the end of their lifespan. This not only reduces the demand for virgin steel production but also minimizes the environmental impact associated with the extraction and manufacturing of new materials. By using recycled steel, transportation infrastructure projects can contribute to a circular economy and reduce their carbon footprint. 4. Design flexibility: Steel H-beams offer design flexibility, allowing engineers to create efficient and innovative transportation infrastructure solutions. Their high strength-to-weight ratio enables the construction of lighter structures, reducing the overall material consumption and transportation costs during construction. Additionally, their ability to span long distances without intermediate support pillars can reduce the need for additional materials and land use, making the infrastructure more environmentally friendly. 5. Resilience: Steel H-beams have excellent resistance to natural disasters, such as earthquakes and hurricanes. This resilience ensures the safety and stability of transportation infrastructure, reducing the risks associated with major events. By minimizing the damage caused by natural disasters, steel H-beams contribute to the sustainable operation and longevity of transportation networks. Overall, steel H-beams play a vital role in creating sustainable transportation infrastructure by offering durability, cost-effectiveness, recyclability, design flexibility, and resilience. By incorporating these beams into construction projects, we can enhance the longevity, safety, and environmental friendliness of transportation networks, thus contributing to a more sustainable future.

- Q: Can steel H-beams be used in industrial warehouses?

- Yes, steel H-beams can be used in industrial warehouses. Steel H-beams are commonly used as structural supports in industrial buildings due to their strength, durability, and ability to bear heavy loads. They provide stability and support to the overall structure of the warehouse, making them an ideal choice for industrial applications.

- Q: What are the different types of steel H-beam connections used in airport terminals?

- Airport terminals commonly utilize various types of steel H-beam connections to provide structural support and stability. These connections serve the purpose of ensuring the integrity of the terminal building. 1. Welded Connections: Among the most frequently used steel H-beam connections in airport terminals are welded connections. This type of connection involves joining the H-beams through welding techniques, including arc welding or gas welding. Welded connections offer a robust and long-lasting connection that guarantees the structural integrity of the terminal building. 2. Bolted Connections: Another type of connection employed in airport terminals is bolted connections. This method entails securing the H-beams together using bolts and nuts. Bolted connections are typically utilized when the H-beams require easy disassembly or replacement. They offer flexibility, ease of maintenance, and the possibility to adjust the connection if necessary. 3. Moment Connections: Designed to withstand bending moments caused by external forces such as wind or seismic loads, moment connections are more complex. They involve additional components like plates and stiffeners. Moment connections enhance rigidity and strength in the terminal structure, ensuring stability and safety. 4. Shear Connections: Shear connections resist horizontal forces on the H-beams, such as those caused by wind or seismic activity. These connections facilitate the transfer of shear forces between the beams and the supporting structure. Shear connections may involve gusset plates, bolts, or welding techniques to ensure proper load transfer and structural stability. 5. Composite Connections: Composite connections integrate steel H-beams with other materials like concrete or timber to establish a stronger and more efficient connection. This type of connection is beneficial when additional strength or load-bearing capacity is required. Composite connections enhance structural performance and versatility in airport terminal construction. In conclusion, the selection of steel H-beam connections for airport terminals relies on factors such as design requirements, structural loads, and construction methods. Choosing the appropriate connection type is crucial to ensure the safety, durability, and efficiency of the terminal building.

- Q: What are the factors to consider when designing with steel H-beams?

- When designing with steel H-beams, there are several important factors to consider. First and foremost, the load-bearing capacity of the H-beams must be carefully assessed. This involves calculating the maximum expected loads, such as the weight of the structure itself, any additional loads it will bear (such as people or machinery), and any external forces it may experience (such as wind or seismic activity). The dimensions and material properties of the H-beams must be chosen to ensure they can safely support these loads without deformation or failure. Another critical factor to consider is the span or distance between supports. The longer the span, the larger and stronger the H-beams will need to be to prevent excessive deflection. It is essential to choose the appropriate beam size and spacing to ensure structural integrity and avoid any potential sagging or buckling. The connection details between the H-beams and other structural members should also be carefully considered. The connections must be designed to effectively transfer the loads and maintain the overall stability of the structure. Factors such as the type of connection (welded, bolted, or a combination), the size and number of bolts or welds, and the connection's resistance to shear and moment forces should all be evaluated. Additionally, the potential for corrosion and environmental factors must be taken into account when designing with steel H-beams. Steel is susceptible to corrosion, and if the structure will be exposed to moisture, chemicals, or other corrosive elements, appropriate protective measures such as coating or galvanizing may be necessary to extend the lifespan of the H-beams. Lastly, the cost and availability of the steel H-beams should also be considered. Different sizes and grades of steel will have varying costs and availability, so it is important to balance the desired structural performance with practical considerations. Overall, when designing with steel H-beams, it is crucial to carefully evaluate the load-bearing capacity, span, connection details, corrosion resistance, and cost factors to ensure a safe and structurally sound design.

- Q: Are there any design guidelines or codes for using steel H-beams?

- Yes, there are design guidelines and codes for using steel H-beams. These guidelines and codes are provided by various organizations such as the American Institute of Steel Construction (AISC) in the United States or the Eurocodes in Europe. These guidelines cover various aspects including the design, fabrication, and erection of steel H-beams to ensure their structural integrity and safety in different applications.

- Q: Can steel H-beams be used for data centers?

- Yes, steel H-beams can be used for data centers. They are commonly used as structural supports in buildings and can provide the necessary strength and stability required for data center infrastructure.

Send your message to us

GB Standard Steel H Beam 388mm-400mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords