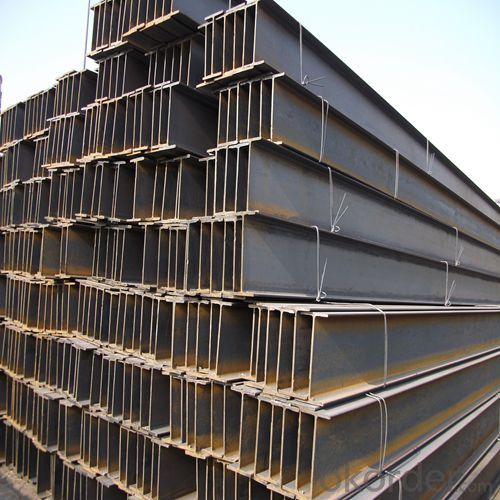

H-Beam Hot Rolled Steel Structure Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering H-Beam Hot Rolled Steel Structure Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

H-Beam Hot Rolled Steel Structure Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's H-Beam Hot Rolled Steel Structure Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Hot Rolled Structural Steel H Beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

SIZE(mm) | DIMENSION(kg/m) |

100*100 | 16.9 |

125*125 | 23.6 |

150*75 | 14 |

150*150 | 31.1 |

148*100 | 20.7 |

198*99 | 17.8 |

200*100 | 20.9 |

248*124 | 25.1 |

250*125 | 29 |

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Structural Steel H Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel H-beams be used in cold storage or refrigeration facilities?

- Yes, steel H-beams can be used in cold storage or refrigeration facilities. Steel H-beams are commonly used in construction due to their strength and durability. In cold storage or refrigeration facilities, where low temperatures are maintained, steel H-beams provide the necessary structural support for the facility. They can withstand the temperature fluctuations and extreme conditions associated with refrigeration, making them suitable for use in these environments. Additionally, steel is a good thermal conductor, which means it can efficiently transfer heat, ensuring that the cold storage or refrigeration facility maintains the desired temperature levels.

- Q: What are the typical spans and spacing for steel H-beams in roof structures?

- The typical spans and spacing for steel H-beams in roof structures can vary depending on several factors such as the design of the roof, the load requirements, and the regional building codes. However, there are some general guidelines that can be followed. For smaller residential or light commercial roof structures, the typical span for steel H-beams can range from 10 to 25 feet. The spacing between the beams can vary but is typically around 4 to 8 feet. In larger commercial or industrial roof structures, the spans can be much larger, reaching up to 100 feet or more. The spacing between the beams in these cases can also vary but is usually between 10 to 20 feet. It is important to note that these are just general guidelines and the specific requirements for spans and spacing should be determined by a structural engineer or an architect. They will consider factors such as the weight of the roof materials, the anticipated snow or wind loads, and any specific building code requirements for the area. It is crucial to adhere to the proper spans and spacing to ensure the structural integrity and safety of the roof structure. Consulting with a professional is always recommended to determine the most suitable spans and spacing for steel H-beams in roof structures.

- Q: Are steel H-beams suitable for use in the construction of entertainment venues or stadiums?

- Yes, steel H-beams are suitable for use in the construction of entertainment venues or stadiums. Steel H-beams are known for their high strength-to-weight ratio, making them ideal for supporting heavy loads and providing structural stability. They can effectively withstand the dynamic forces and vibrations experienced in entertainment venues or stadiums, ensuring the safety and durability of the structure. Additionally, steel H-beams allow for flexible design options and can be easily customized to meet specific construction requirements, making them a popular choice in the industry.

- Q: Can steel H-beams be used for residential garages?

- Certainly! Residential garages can indeed utilize steel H-beams. These beams are frequently employed in construction owing to their robustness and endurance. They offer exceptional structural reinforcement, rendering them well-suited for purposes such as garage construction. Steel H-beams present several benefits, including their ability to withstand bending and warping, which ensures the stability of the garage's framework. Moreover, these beams possess a remarkable load-bearing capacity, enabling them to bear heavy weights, such as vehicles and stored items. By opting for steel H-beams in the establishment of residential garages, one can achieve a resilient and long-lasting structure that provides ample safeguarding for both vehicles and belongings.

- Q: How do steel H-beams perform in earthquake-prone regions?

- Steel H-beams are considered to be one of the most effective structural elements in regions prone to earthquakes. The H shape and composition of these beams make them highly resistant to seismic forces, resulting in better performance compared to other building materials. To begin with, the H shape of the beams provides great strength and load-bearing capacity. This design distributes the weight evenly along the length of the beam, enabling it to withstand the lateral forces generated by earthquakes. This attribute allows H-beams to resist bending and deformation, which is crucial for maintaining the structural integrity of a building during seismic events. Furthermore, steel itself is a durable and flexible material. It exhibits exceptional tensile strength, allowing it to stretch and absorb the energy generated during an earthquake. This characteristic prevents the beams from fracturing or collapsing under the intense shaking and ground motion experienced in earthquake-prone regions. In addition, engineers can fabricate steel H-beams with specific seismic design principles in mind. Strategies such as moment-resisting frames or base isolation systems can be incorporated, further enhancing the seismic performance of these beams. These design techniques help dissipate and redirect seismic forces away from the building, reducing the potential for structural damage. Moreover, steel H-beams offer advantages in terms of construction speed and versatility. They can be prefabricated offsite and easily assembled on-site, saving time and resources during construction. This flexibility also allows for the creation of complex building designs, which can be crucial in areas with limited space or unique architectural requirements. In conclusion, steel H-beams are highly suitable for earthquake-prone regions due to their exceptional strength, flexibility, and adaptability. Their unique shape, material properties, and the ability to incorporate seismic design principles make them a reliable choice for ensuring the safety and resilience of structures in areas susceptible to seismic activity.

- Q: What are the considerations for selecting the appropriate size of steel H-beams?

- The selection of the appropriate size of steel H-beams involves several considerations. Firstly, the load requirements must be taken into account, including the weight of the structure and any additional loads it will bear. The span and height of the beam, as well as the required deflection and stiffness, should also be considered. Additionally, the material properties, such as yield strength and resistance to corrosion, should align with the intended application. Finally, economic factors, such as cost and availability, should be weighed when selecting the appropriate size of steel H-beams.

- Q: What are the different methods of reinforcing steel H-beams?

- Different methods are available to reinforce steel H-beams, which are commonly used in construction to provide structural support. These methods aim to improve the strength, durability, and load-bearing capacity of H-beams, ensuring their optimal performance in various applications. 1. Welding: Welding is a widely used method to strengthen steel H-beams. By welding two or more H-beams together, a stronger and more rigid structure is created. This is achieved by melting the edges of the beams and fusing them together using heat and pressure. Welding can also be employed to attach additional steel plates or angles to the H-beam, further enhancing its overall structure. 2. Shear Connectors: Shear connectors are effective in reinforcing H-beams, especially in composite construction. These connectors, typically steel studs or bars, are welded onto the top flange of the H-beam. Their purpose is to transfer shear forces between the concrete slab and the steel beam, thereby improving the structural integrity and load-carrying capacity of the H-beam. 3. Steel Plates: Steel plates are commonly used to reinforce H-beams, particularly when dealing with heavy loads or long spans. These plates are usually bolted or welded to the web or flanges of the H-beam, providing additional strength and stiffness. The size and thickness of the steel plates can be customized based on the specific project requirements. 4. Composite Beams: Composite beams involve combining a steel H-beam with a concrete slab. This method entails placing the concrete slab on top of the H-beam and connecting them together using shear connectors like steel studs or bars. Composite beams offer numerous advantages, including increased load-carrying capacity, improved fire resistance, and enhanced overall stiffness. 5. Reinforced Concrete Encasement: Reinforcing H-beams through reinforced concrete encasement is another method. This technique involves wrapping the H-beam with reinforced concrete, which is achieved by constructing formwork around the beam and pouring concrete into it. The concrete encasement enhances the strength and stiffness of the H-beam, providing additional resistance against bending, shear, and other forces. It is important to note that the choice of reinforcing method depends on specific project requirements, such as load requirements, span length, construction constraints, and design considerations. Consulting with a structural engineer or construction professional is highly recommended to determine the most suitable method for reinforcing steel H-beams in a given application.

- Q: H steel compared with ordinary steel in the end what are the advantages and disadvantages?

- H section steel is a kind of economical and economical cutting surface profile (other cold bending thin wall steel, pressed steel plate, etc.). Because of the reasonable cross-section shape, they can make steel more effective and improve the bearing capacity. Unlike ordinary I-beam, the flange of H steel is widened, and the inner and outer surfaces are usually parallel so that it is easy to connect with high strength bolts and other components. Its size constitutes a reasonable series, complete model, easy to design and use. (in addition to crane girders)

- Q: How is the weight of H steel calculated?

- RA=RB=P/2 Mc=Mmax=Pl/4 fc=fmax=Pl^3/48EI A= B=Pl^2/16EI symbol and theta theta P - Q - N; concentrated load, uniform load, N; R - bearing force, the direction of the action is positive, N; M - bending moment, the compression of the upper section, lower tension is positive, Nm; Q, the shear. The adjacent section of the torque in a clockwise direction is positive, N; F, deflection, downward displacement is positive, mm; angle theta, clockwise rotation as positive degrees; E - Gpa; I - elastic modulus, cross-sectional moment of inertia, m^4; L = x/. =x'/l, zeta, alpha beta gamma = a/l, =b/l, =c/l from two aspects: first, from the beam considering shear stress second, the bending stress is considered. The maximum available shear strength of steel can be found from the steel sheet, T, Tmax=Q/Ib[BH^2/8-< (B-b), h^2>/8]: Tmax is the maximum shear strength. The maximum shear load of the beam can be calculated by replacing the available shear strength T. Q is the uniformly distributed load, and the section moment of inertia of I is B, which can be found in the steel table. (cm^4) the maximum width of the section of i-beam. B is the minimum width of I-beam section, h is the height of minimum width section of i-beam. H is the calculation of the height normal stress of the maximum width section of I-beam: Ysigma=M/W, M=, maximum bending moment = load, travel distance, W= flexural modulus. With the maximum allowable stress of Ysigma=, the maximum value of the load can be obtained.

- Q: Can steel H-beams be used in the construction of recreational centers or gyms?

- Indeed, recreational centers or gyms can utilize steel H-beams in their construction. These beams, widely employed in the construction sector, are renowned for their structural resilience and endurance. They possess exceptional load-bearing capabilities, thus making them ideal for supporting extensive spans and hefty loads commonly encountered in recreational centers or gyms. Moreover, the fabrication and assembly of steel H-beams are both effortless and expedient, permitting efficient construction and adaptability in design. By incorporating steel H-beams into the construction of recreational centers or gyms, a sturdy and enduring structure is guaranteed, capable of withstanding the rigorous demands of such facilities.

Send your message to us

H-Beam Hot Rolled Steel Structure Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords