Steel-frame Formwork for Corner

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

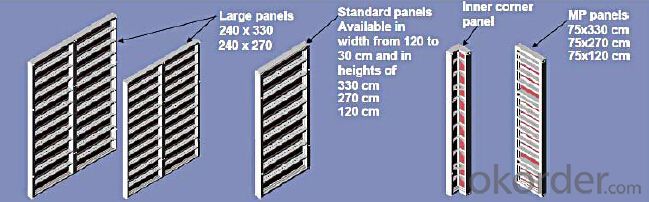

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

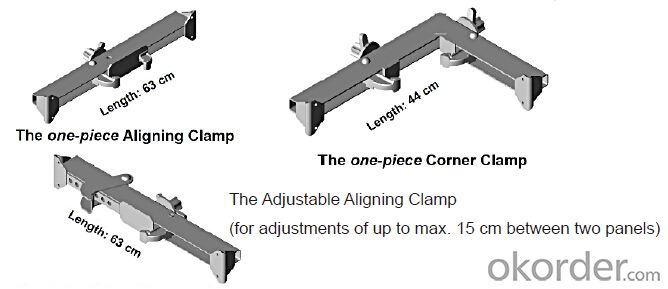

◆ Kinds of panel connectors.

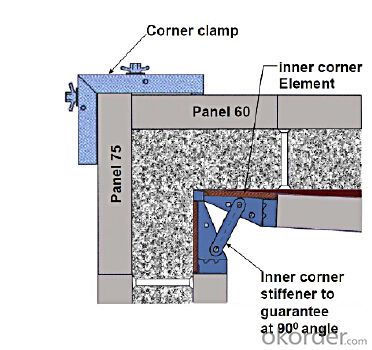

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for both standard and non-standard concrete shapes?

- Yes, steel formwork can be used for both standard and non-standard concrete shapes. Steel is a versatile material that can be easily molded and shaped to create various formwork designs. It offers high strength and durability, making it suitable for complex and intricate concrete shapes. Steel formwork can be fabricated to meet specific project requirements, allowing for customization and flexibility in formwork design. Whether it is a standard rectangular shape or a unique and irregular design, steel formwork can be used effectively to mold and shape concrete structures of any shape and size.

- Q: Can steel formwork be used for both residential and commercial renovations?

- Indeed, both residential and commercial renovations can make use of steel formwork. Renowned for its durability and strength, steel formwork proves itself suitable for diverse construction endeavors. Whether it involves a residential renovation, such as extending a property, or a commercial renovation, like refurbishing an office space, steel formwork delivers the required support and stability throughout the construction phase. Moreover, steel formwork readily lends itself to customization and adjustment to meet various project specifications, rendering it a versatile choice for both residential and commercial renovations.

- Q: Can steel formwork be used for precast concrete tanks?

- Yes, steel formwork can be used for precast concrete tanks. Steel formwork offers strength, durability, and flexibility, making it suitable for constructing various types of precast concrete structures, including tanks.

- Q: Can steel formwork be used for tunnel portals?

- Yes, steel formwork can be used for tunnel portals. Steel formwork is a versatile and durable option for constructing tunnel portals due to its strength and ability to withstand the forces and pressures exerted by the surrounding soil and rock. Steel formwork can be fabricated to any shape and size required for tunnel portals and can be easily assembled and disassembled, making it a practical choice for tunnel construction. Additionally, steel formwork provides a smooth surface finish, which is important for tunnel portals as it allows for efficient flow of traffic and reduces the risk of damage to vehicles. Overall, steel formwork is a suitable and commonly used method for constructing tunnel portals.

- Q: What are the different types of steel formwork systems?

- There are several different types of steel formwork systems commonly used in construction, including traditional steel formwork, modular steel formwork, tunnel formwork, and climbing formwork.

- Q: Can steel formwork be used for architectural concrete beams?

- Indeed, architectural concrete beams can be constructed using steel formwork. The utilization of steel formwork yields numerous benefits in contrast to conventional wooden formwork. These advantages encompass enhanced longevity and the ability to be reused. Steel formwork stands as a sturdier and more inflexible alternative, facilitating the meticulous and precise construction of architectural concrete beams. Furthermore, it delivers a sleek and uniform surface finish, a crucial element in attaining the desired aesthetic appeal of the beams. Moreover, the assembly, disassembly, and transportation of steel formwork can be effortlessly executed, rendering it a pragmatic option for the construction of architectural concrete beams.

- Q: Can steel formwork be used for both interior and exterior applications?

- Yes, steel formwork can be used for both interior and exterior applications. Steel formwork is highly durable and can withstand various weather conditions, making it suitable for both indoor and outdoor construction projects. Its versatility and strength make it a preferred choice for many construction applications.

- Q: Can steel formwork be easily modified or adjusted during concrete placement?

- Concrete placement can easily incorporate modifications or adjustments when using steel formwork. The versatility and flexibility of steel formwork enable effortless modifications or adjustments according to the needs of the concrete structure. Steel formwork systems typically consist of adjustable components like panels, beams, and props, which can be readily repositioned or relocated to accommodate changes in the design or dimensions of the concrete structure. These adjustable components can be swiftly and securely locked in place, ensuring stability and support during concrete placement. Moreover, steel formwork facilitates the utilization of various formwork accessories like clamps, connectors, and ties, further enhancing its adaptability and ease of modification. In summary, steel formwork offers a highly efficient and flexible solution for adjusting or modifying formwork during concrete placement.

- Q: What is the lifespan of steel formwork compared to other types of formwork?

- The lifespan of steel formwork is generally longer compared to other types of formwork. Steel is a highly durable material that can withstand heavy loads and extreme weather conditions, making it ideal for construction purposes. With proper maintenance and care, steel formwork can last for several decades. In comparison, other types of formwork such as wooden or plastic formwork have a shorter lifespan. Wood is susceptible to rotting, warping, and termite infestation, which can significantly reduce its lifespan. Plastic formwork, while lightweight and easy to handle, may deteriorate over time due to exposure to UV radiation and general wear and tear. Steel formwork also offers the advantage of being reusable. Once a concrete structure is completed, the steel formwork can be dismantled and used for other construction projects, reducing the need for new formwork and minimizing waste. Although steel formwork may require a larger upfront investment compared to other materials, its longer lifespan and reusability make it a cost-effective choice in the long run. Additionally, steel formwork provides excellent structural stability, ensuring the integrity and quality of the concrete structure being formed.

- Q: How does steel formwork handle high concrete pressures?

- Steel formwork is known for its excellent strength and durability, making it highly capable of handling high concrete pressures. When subjected to significant pressure, steel formwork retains its shape and structure, providing a stable and reliable framework for the poured concrete. The strength of steel formwork lies in its ability to withstand the immense forces exerted by the weight and fluidity of the concrete. Steel is inherently strong and has a high load-bearing capacity, enabling it to resist the pressure exerted by the concrete during the pouring and curing process. Moreover, steel formwork is designed with reinforcement and bracing systems that further enhance its ability to handle high concrete pressures. Reinforcements, such as steel bars or mesh, are strategically placed within the formwork structure to provide additional support and prevent any deformation or failure. These reinforcements distribute the stress evenly across the formwork, minimizing the risk of damage due to excessive pressure. Additionally, steel formwork is often designed with strong connection points and interlocking mechanisms. These features ensure that the individual components of the formwork system remain securely connected, preventing any collapse or failure under high concrete pressures. The interlocking nature of steel formwork also helps to maintain the integrity of the structure and prevent any leakage or seepage of the concrete. In summary, steel formwork is specifically engineered to handle high concrete pressures effectively. The inherent strength of steel, combined with reinforcement and bracing systems, ensures that the formwork can withstand the immense forces exerted by the weight and fluidity of the concrete. Its ability to retain its shape and stability under pressure makes steel formwork a reliable and widely used choice in construction projects requiring high concrete pressures.

Send your message to us

Steel-frame Formwork for Corner

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords