Steel-Frame Formwork SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

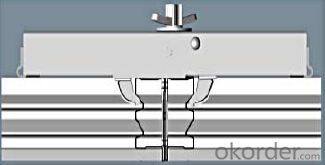

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for both small-scale and large-scale construction projects?

- Steel formwork is suitable for both small-scale and large-scale construction projects. Its versatility allows it to be customized to meet the specific requirements of any construction project. With excellent durability and strength, steel formwork can withstand the pressures exerted during large-scale projects. It is easily assembled and disassembled, making it efficient for use on construction sites of any size. Moreover, steel formwork provides a smooth and consistent finish, guaranteeing high-quality results regardless of the project's scale. Therefore, whether it is a small residential building or a large commercial complex, steel formwork can effectively achieve the desired construction objectives.

- Q: What are the different finishes available for steel formwork?

- There are several different finishes available for steel formwork, depending on the desired appearance and functionality of the final product. Some of the most common finishes include: 1. Smooth finish: This is the most basic finish option, where the steel formwork is left as is without any additional treatment. It provides a clean and simple appearance, but it may not be suitable for applications where increased durability or corrosion resistance is required. 2. Galvanized finish: Steel formwork can be hot-dip galvanized, which involves coating the surface of the steel with a layer of zinc. This finish provides excellent corrosion resistance, making it suitable for outdoor applications or structures exposed to moisture. 3. Powder coating: Powder coating is a popular finish option for steel formwork. It involves applying a dry powder to the surface of the steel and then baking it in an oven to create a durable and attractive finish. Powder coating provides excellent corrosion resistance and can be customized to achieve different colors and textures. 4. Epoxy coating: Epoxy coatings are commonly used in industrial settings where chemical resistance is required. These coatings create a protective layer on the steel formwork, making it resistant to chemicals, abrasion, and moisture. Epoxy coatings can also be customized with different colors and textures. 5. Paint finish: Steel formwork can be painted with various types of paint, such as enamel or latex, to achieve a desired appearance. Paint finishes provide some level of corrosion resistance, but they may not be as durable as other finish options. It is important to consider the specific requirements and conditions of the project when selecting the appropriate finish for steel formwork. Factors such as the intended use, exposure to elements, and aesthetic preferences should be taken into account to ensure the desired outcome.

- Q: Can steel formwork be used for both straight and curved walls?

- Yes, steel formwork can be used for both straight and curved walls. Steel formwork offers high strength and durability, making it suitable for shaping walls of various shapes and sizes. It is highly flexible and can be easily adjusted and customized to create both straight and curved walls. The steel formwork system allows for precise and accurate construction, ensuring that the walls are built to the desired specifications. Additionally, steel formwork is reusable, making it a cost-effective choice for both straight and curved wall construction projects.

- Q: I would like to ask the bridge column (D110) steel template thickness should be how much

- Parting is generally divided according to the release of simple or rounded way, according to the height of the construction plans and schedule requirements. Generally, the height of the column template is set at 1.52 or 0 5m in order to be easy to use.

- Q: What are the common safety guidelines when working with steel formwork in confined spaces?

- When working with steel formwork in confined spaces, some common safety guidelines include ensuring proper ventilation to prevent the buildup of hazardous gases, regularly monitoring the atmosphere for toxic substances, providing adequate lighting and emergency exit routes, wearing appropriate personal protective equipment such as gloves, safety glasses, and respiratory protection, training workers on the potential hazards and safe work practices, and having a standby person outside the confined space to monitor and assist if needed.

- Q: How does steel formwork contribute to the overall safety of workers?

- Steel formwork contributes to the overall safety of workers in several ways. Firstly, steel formwork is known for its strength and durability, providing a stable and secure structure for workers to perform their tasks. This stability minimizes the risk of accidents and collapses, ensuring the safety of workers. Additionally, steel formwork is designed to be fire-resistant, offering protection in case of fire emergencies. This feature significantly reduces the risk of injuries and provides workers with valuable time to evacuate the area safely. Moreover, steel formwork is engineered to be resistant to various weather conditions, such as strong winds and heavy rains. This resistance prevents formwork from becoming unstable or collapsing during adverse weather, minimizing the risk of accidents and injuries for workers on-site. Furthermore, steel formwork is typically designed with safety features such as non-slip surfaces and handrails, enhancing worker safety by providing better grip and stability when moving around the structure. These features help prevent slips, trips, and falls, which are common causes of accidents on construction sites. Another important aspect is that steel formwork is reusable and can be easily assembled and disassembled. This reduces the need for workers to carry heavy materials or tools, decreasing the risk of strain injuries and fatigue-related accidents. Lastly, steel formwork is designed to ensure proper support and alignment, minimizing the risk of structural failures or collapses during concrete pouring. This precise alignment ensures the stability of the structure and reduces the likelihood of accidents that could endanger workers' safety. In conclusion, steel formwork plays a crucial role in enhancing the overall safety of workers. Its strength, durability, fire resistance, weather resistance, non-slip surfaces, and proper support contribute significantly to creating a secure working environment, reducing the risk of accidents, injuries, and structural failures.

- Q: How does steel formwork affect the cost of construction?

- Steel formwork can have a significant impact on the overall cost of construction. While it may require a higher initial investment compared to traditional formwork materials such as wood or plywood, steel formwork offers several advantages that can help offset the increased cost. Firstly, steel formwork is incredibly durable and long-lasting, which means it can be reused multiple times. Unlike wood or plywood formwork, steel formwork does not warp, rot, or degrade over time. This reusability factor reduces the need for frequent formwork replacements, thus saving on material costs in the long run. Additionally, steel formwork provides superior strength and stability, allowing for the construction of complex and high-quality concrete structures. This strength enables the use of thinner formwork elements, reducing the overall weight of the formwork system. As a result, less labor and equipment are required for handling and installation, leading to cost savings in terms of manpower and machinery. Furthermore, steel formwork allows for faster construction cycles. The smooth and precise surface finish provided by steel formwork reduces the need for extensive finishing work. This streamlined construction process saves time, ultimately reducing labor costs and project timelines. Moreover, steel formwork offers enhanced safety on construction sites. Its sturdy nature and secure connections ensure stability during concrete pouring and curing, minimizing the risk of accidents or structural failures. This improved safety aspect can help in reducing insurance costs and potential legal liabilities. Lastly, steel formwork is highly adaptable and customizable. It can be easily modified and adjusted to accommodate various design requirements, making it suitable for a wide range of construction projects. This flexibility helps optimize material usage and ensures minimal wastage, thereby reducing overall construction costs. In summary, although steel formwork may initially incur a higher cost, its long-term benefits such as reusability, strength, speed, safety, and adaptability contribute to overall cost savings in construction projects. Its durability and efficiency make it a cost-effective choice that can positively impact the quality, timeline, and budget of any construction undertaking.

- Q: Can steel formwork be used for projects with aggressive concrete mixes?

- Yes, steel formwork can be used for projects with aggressive concrete mixes. Steel formwork is known for its strength, durability, and resistance to various environmental factors. Aggressive concrete mixes typically contain higher amounts of chemicals such as chlorides, sulfates, or alkalis, which can be corrosive to some materials. However, steel formwork is usually resistant to these aggressive chemical attacks and can withstand the harsh conditions associated with aggressive concrete mixes. It is important to ensure that the steel formwork used is properly coated or treated to enhance its resistance to corrosion and chemical attacks. Regular maintenance and inspection of the formwork are also necessary to identify and address any signs of deterioration or damage. Overall, steel formwork can be a suitable choice for projects with aggressive concrete mixes due to its strength and resistance to chemical attacks.

- Q: How does steel formwork handle different concrete surface slip resistance?

- Steel formwork, a versatile and robust material commonly used in construction, is essential for shaping and supporting concrete during the curing process. In terms of managing slip resistance on concrete surfaces, steel formwork offers numerous benefits. Firstly, steel formwork guarantees a smooth and uniform surface for pouring concrete, minimizing variations in slip resistance. Unlike materials like wood, steel does not warp or deform, ensuring consistent contact between the formwork and concrete. This uniformity promotes a more consistent concrete surface, reducing the risk of uneven slip resistance. Furthermore, steel formwork allows for the utilization of different surface treatments and coatings that can enhance slip resistance. For example, before pouring the concrete, anti-slip coatings or aggregates can be applied to the formwork surface, creating a textured surface that improves traction. These treatments can be customized to meet specific requirements for slip resistance, providing design flexibility. Moreover, steel formwork is extremely durable and resistant to wear and tear. This durability ensures that the formwork maintains its structural integrity throughout the concrete pouring process, minimizing the occurrence of surface irregularities that could affect slip resistance. Additionally, steel formwork is easy to clean and maintain, ensuring that any contaminants or debris that could impact slip resistance are promptly addressed. In conclusion, steel formwork effectively manages different levels of slip resistance on concrete surfaces by providing a smooth and consistent surface, allowing for customization through various treatments, and maintaining durability to prevent surface irregularities. Its strength and versatility make steel formwork a dependable choice for construction projects where slip resistance is a concern.

- Q: Can steel formwork be used for both flat and sloped concrete surfaces?

- Yes, steel formwork can be used for both flat and sloped concrete surfaces. Steel formwork is known for its versatility and durability, making it suitable for various types of concrete structures. It can be easily adjusted and shaped to create both flat and sloped surfaces, allowing for the construction of diverse architectural designs. Additionally, steel formwork provides excellent support and stability to the concrete during the pouring and curing process, ensuring a high-quality and uniform finish on both flat and sloped surfaces.

Send your message to us

Steel-Frame Formwork SF-140

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords