Steel Frame corner link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

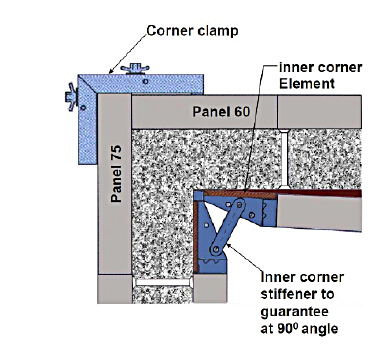

◆ The selection of panels.

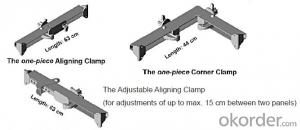

◆ Kinds of panel connectors.

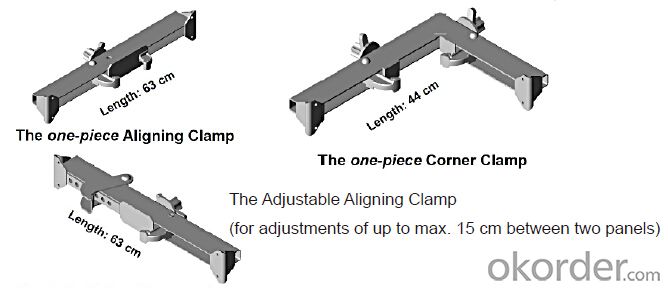

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: What are the typical fire resistance ratings of steel formwork systems?

- The typical fire resistance ratings of steel formwork systems can vary depending on several factors such as the type of steel used, the thickness of the steel, and the overall design and construction of the formwork system. However, in general, steel formwork systems are known for their high fire resistance properties. Steel is a non-combustible material, which means it does not contribute to the spread or intensity of fire. It has a high melting point and does not ignite or release flammable gases when exposed to fire. As a result, steel formwork systems can withstand high temperatures and provide excellent fire resistance. In many cases, steel formwork systems are designed to meet or exceed specific fire resistance ratings specified by building codes and regulations. These ratings are typically expressed in terms of a time period, such as 1 hour, 2 hours, or more, which represents the duration for which the formwork system can maintain its structural integrity and protect against fire. The fire resistance ratings of steel formwork systems can be further enhanced by incorporating additional fire protection measures such as fire-resistant coatings or insulation materials. These measures can provide an extra layer of protection and increase the overall fire resistance of the formwork system. It is important to note that fire resistance ratings can also depend on other factors such as the presence of fire-resistant materials in the surrounding structure and the overall fire safety measures implemented in the building. Therefore, it is crucial to consult with structural engineers, architects, and fire safety experts to determine the specific fire resistance requirements and ratings for steel formwork systems in a particular construction project.

- Q: Can steel formwork be used for underground tunnels?

- Yes, steel formwork can be used for underground tunnels. Steel formwork is highly durable and can withstand the pressure and load of the surrounding soil in underground conditions. It provides excellent strength and stability to support the tunnel construction process and ensures the safety and integrity of the structure.

- Q: What are the common safety precautions when working with steel formwork in high winds?

- Some common safety precautions when working with steel formwork in high winds include securing the formwork properly to prevent it from being blown away or unstable, regularly inspecting the formwork for any damage or weaknesses that may be exacerbated by the wind, using appropriate personal protective equipment (PPE) such as helmets and safety harnesses, and ensuring that workers are trained on how to safely work in high wind conditions. Additionally, it is important to monitor weather conditions and suspend work if winds become too strong to ensure the safety of workers.

- Q: Are there any specific quality control measures for steel formwork construction?

- Yes, there are specific quality control measures for steel formwork construction. These measures are put in place to ensure that the steel formwork meets the required standards and specifications, and that it is safe and reliable for use in construction projects. One of the main quality control measures is the inspection of the steel formwork materials before they are used. This includes checking for any defects, such as cracks, rust, or other damage, that could affect the integrity and strength of the formwork. The materials should also be checked for proper dimensions and smoothness to ensure they fit together correctly and provide a smooth surface finish. Another quality control measure is the inspection of the steel formwork during and after the construction process. This involves checking that the formwork is properly assembled and secured, with all connections and joints correctly aligned and tightened. The formwork should also be inspected for any signs of deformation, such as bending or twisting, which could compromise its structural integrity. In addition to inspections, quality control measures also involve testing the steel formwork to assess its strength and durability. This can include conducting load tests to determine the maximum load capacity of the formwork, as well as tests to evaluate its resistance to environmental factors such as corrosion, fire, and moisture. Documentation and record-keeping are also important quality control measures for steel formwork construction. This includes maintaining detailed records of inspections, tests, and any repairs or modifications made to the formwork. This documentation ensures that the construction process is traceable and can be audited if necessary. Overall, these quality control measures for steel formwork construction are essential to ensure that the formwork is of high quality, meets the required standards, and provides a safe and reliable support system for concrete during construction.

- Q: What are the different types of formwork connectors used in steel formwork?

- There are several different types of formwork connectors used in steel formwork, including wedge clamps, wedge bolts, pin and wedge systems, and snap ties. These connectors are essential for securely joining formwork panels together and ensuring the stability and strength of the formwork structure.

- Q: How does steel formwork affect the overall energy efficiency of the structure?

- Steel formwork can have a significant impact on the overall energy efficiency of a structure. One of the main benefits of using steel formwork is its ability to provide a high level of thermal insulation. Steel has a low thermal conductivity, meaning it does not easily transfer heat. This property helps to minimize heat loss or gain through the walls, floors, and ceilings of the structure. By using steel formwork, the building envelope can be better sealed, reducing air infiltration and improving the overall airtightness of the structure. This prevents unwanted air leakage, which can lead to energy loss and reduced energy efficiency. Steel formwork also allows for better control of moisture and humidity levels, which is crucial for maintaining a comfortable indoor environment and preventing mold or moisture-related issues. Additionally, steel formwork provides a durable and long-lasting construction solution. It can withstand extreme weather conditions, seismic activities, and other external forces, ensuring the structural integrity of the building for many years. This durability reduces the need for frequent repairs or replacements, which can save energy and resources in the long run. Furthermore, steel formwork is a sustainable choice as it is often made from recycled materials and is itself recyclable at the end of its lifespan. The use of recycled steel reduces the carbon footprint associated with construction and helps conserve natural resources. The recyclability of steel formwork also means that it can be repurposed or reused in future projects, further reducing waste and environmental impact. In summary, steel formwork positively affects the overall energy efficiency of a structure by providing excellent thermal insulation, improved airtightness, moisture control, durability, and sustainability. By choosing steel formwork, builders can create energy-efficient buildings that are environmentally friendly and cost-effective in the long term.

- Q: How does steel formwork compare to aluminum formwork in terms of cost?

- In terms of cost, steel formwork generally tends to be more expensive compared to aluminum formwork. Steel is a stronger and more durable material, which results in higher production and material costs. Additionally, steel formwork requires more labor for handling and installation due to its heavier weight. On the other hand, aluminum formwork is lighter and easier to handle, reducing labor costs and increasing efficiency during construction. Moreover, aluminum formwork can be reused multiple times, resulting in considerable cost savings over multiple projects. Overall, while steel formwork offers superior strength and durability, it comes at a higher initial cost compared to aluminum formwork due to material and labor considerations.

- Q: How does steel formwork handle different concrete surface repair techniques?

- Steel formwork is a versatile and durable option for handling different concrete surface repair techniques. One of the key advantages of steel formwork is its ability to withstand the pressures and stresses associated with concrete repairs. When it comes to techniques such as patching or resurfacing, steel formwork provides a strong and stable framework to contain the concrete mixture. It can withstand the weight of the repair materials and the pressure exerted by the concrete as it sets and cures. This ensures that the repair is properly contained and that the desired shape and dimensions are achieved. Steel formwork also offers flexibility in terms of shape and design. It can be easily customized to accommodate different repair requirements, whether it involves straight surfaces, curves, or complex geometries. The strength of steel allows for the creation of intricate formwork structures that can handle even the most challenging repair projects. Moreover, steel formwork provides excellent reusability and durability. It can be used repeatedly without significant wear and tear, making it a cost-effective solution for multiple repair projects. This durability ensures that the formwork remains intact throughout the repair process, maintaining the integrity of the repair and preventing any potential issues. Furthermore, steel formwork is resistant to moisture and chemicals, which are often present in concrete repairs. This resistance ensures that the formwork remains in good condition and does not corrode or deteriorate when in contact with the repair materials. This is particularly important for long-term repairs where the formwork may be in place for an extended period. In conclusion, steel formwork is a reliable and effective option for handling different concrete surface repair techniques. Its strength, flexibility, reusability, and resistance to moisture and chemicals make it an ideal choice for containing and shaping the repair materials, ensuring a successful and durable repair.

- Q: Are there any specific design considerations for steel formwork systems?

- Yes, there are several specific design considerations for steel formwork systems. These include factors such as the load-bearing capacity of the system, its stability and rigidity, ease of assembly and disassembly, durability, corrosion resistance, and adaptability to different project requirements. Additionally, the design should incorporate safety features like non-slip surfaces, secure connections, and proper bracing to ensure worker safety during construction activities.

- Q: Can steel formwork be used for projects with high concrete durability demands?

- Yes, steel formwork can be used for projects with high concrete durability demands. Steel formwork is known for its strength, durability, and longevity, making it suitable for demanding construction projects. It can withstand heavy loads and provide the necessary support for the concrete during the curing process. Steel formwork also offers excellent dimensional stability, ensuring the accuracy and consistency of the concrete structure. Additionally, steel formwork can be reused multiple times, reducing waste and project costs. However, it is important to ensure proper maintenance and corrosion protection of the steel formwork to maximize its durability and ensure long-term performance.

Send your message to us

Steel Frame corner link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords