Steel-Frame corner link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

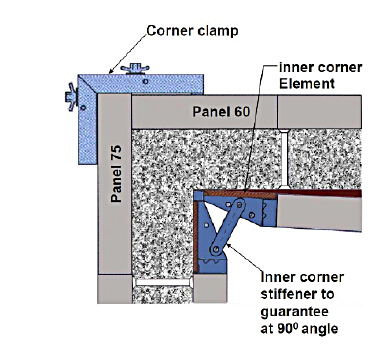

◆ The selection of panels.

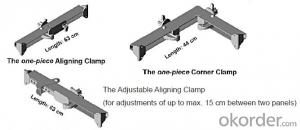

◆ Kinds of panel connectors.

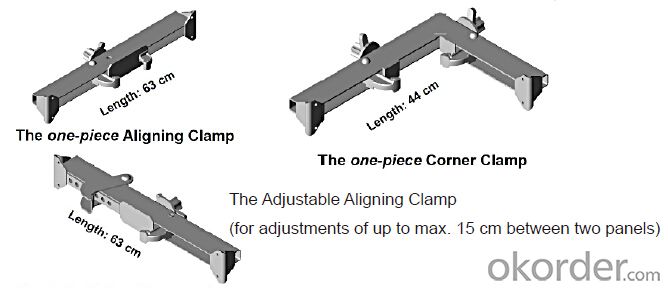

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork affect the overall construction project management?

- Steel formwork can significantly impact the overall construction project management in several ways. Firstly, steel formwork is known for its durability and strength, allowing for faster construction progress and increased efficiency. This leads to shorter construction timelines and reduced project costs. Additionally, steel formwork offers greater flexibility and versatility, enabling construction teams to create complex structures more easily. This enhances the overall project management process by providing more options for design changes and adjustments. Moreover, steel formwork promotes a safer working environment as it is fire-resistant and provides better stability during construction. This ensures the well-being of workers and reduces the risk of accidents, positively impacting project management. Overall, steel formwork plays a crucial role in improving construction project management by enhancing efficiency, flexibility, safety, and cost-effectiveness.

- Q: How does steel formwork prevent concrete shrinkage and cracking?

- Steel formwork prevents concrete shrinkage and cracking by providing a rigid and stable structure that holds the concrete in place during the curing process. This helps to minimize the risk of shrinkage and cracking by providing support and preventing excessive movement of the concrete as it dries and hardens. Additionally, steel formwork allows for proper compaction of the concrete, ensuring that it is evenly distributed and reducing the likelihood of shrinkage and cracking.

- Q: How does steel formwork affect the overall energy efficiency of a structure?

- Steel formwork can have a significant impact on the overall energy efficiency of a structure. Firstly, steel formwork is known for its durability and strength, which allows it to be reused multiple times. This reusability reduces the need for new formwork materials, thereby minimizing waste generation and conserving resources. By reducing the amount of waste produced during construction, the overall environmental impact is reduced, leading to improved energy efficiency. Additionally, steel formwork offers excellent thermal properties. It has a high thermal mass, meaning it can absorb and store heat energy effectively. This characteristic helps regulate the temperature inside the structure, reducing the reliance on heating or cooling systems. By stabilizing the internal temperature, the energy consumption for climate control is reduced, resulting in improved energy efficiency and lower operational costs. Furthermore, steel formwork enables the construction of energy-efficient designs. Its versatility allows for complex shapes and configurations, facilitating the integration of energy-saving elements such as insulation, ventilation systems, and renewable energy technologies. These features contribute to the overall energy performance of the structure, enhancing its efficiency and sustainability. Overall, steel formwork positively impacts the energy efficiency of a structure by reducing waste, providing excellent thermal properties, and enabling energy-efficient designs. By utilizing steel formwork, construction projects can achieve higher levels of sustainability and contribute to a greener and more energy-efficient built environment.

- Q: What are the different types of formwork connectors used in steel formwork?

- There are several types of formwork connectors that are commonly used in steel formwork systems. These connectors play a crucial role in ensuring the stability and strength of the formwork structure. Some of the different types of formwork connectors used in steel formwork include: 1. Wedge Lock Connector: This type of connector is widely used in steel formwork systems. It consists of two separate pieces – a wedge and a lock. The wedge is inserted into the formwork joint, and the lock is then inserted to secure the wedge in place. This connector provides a tight and secure connection, which helps in maintaining the formwork's stability. 2. Pin and Wedge Connector: This connector comprises a pin and a wedge. The pin is inserted through the holes in the formwork panels, and the wedge is then driven into the hole, securing the pin in place. The pin and wedge connector is easy to install and provides a strong connection between the formwork panels. 3. Rapid Clamp Connector: This type of connector is designed to quickly and securely connect steel formwork panels. It consists of a clamp that is tightened around the formwork panel, providing a reliable and sturdy connection. The rapid clamp connector is often used in applications where a quick assembly and disassembly of formwork is required. 4. Hook and Loop Connector: This connector utilizes a hook and loop fastening system to connect the formwork panels. The hook and loop strips are attached to the edges of the formwork panels, allowing them to be easily and firmly connected. This type of connector is commonly used in applications where frequent adjustments or reconfigurations of the formwork are needed. 5. Magnetic Connector: This connector uses magnets to securely connect the steel formwork panels. The magnets are embedded within the formwork panels, allowing them to easily snap together. The magnetic connector is known for its quick installation and disassembly, making it ideal for projects with tight schedules. These are just a few examples of the different types of formwork connectors used in steel formwork. Each connector has its own unique features and benefits, and the selection of the appropriate connector depends on the specific requirements of the project and the formwork system being used.

- Q: Can steel formwork be used for both residential and commercial projects?

- Yes, steel formwork can be used for both residential and commercial projects. Steel formwork is versatile and can be customized to suit different project requirements, making it suitable for a wide range of construction projects, including both residential and commercial buildings.

- Q: Can steel formwork be used for theater construction projects?

- The utilization of steel formwork is applicable to theater construction projects. Steel formwork is composed of temporary or permanent molds constructed from steel, which are employed to mold and support concrete during the construction phase. It is a highly adaptable and long-lasting material that can be utilized for various construction endeavors, including theater construction. The utilization of steel formwork presents several advantages for theater construction projects. Firstly, it provides a considerable amount of strength and stability, guaranteeing that the concrete structures created for theaters are robust and durable. This is of utmost importance in theaters, where safety is a primary concern due to the large gatherings of individuals in these spaces. Furthermore, steel formwork permits the achievement of intricate and complex designs, which are often necessary for theater construction. The malleability of steel formwork enables the creation of personalized shapes, curves, and patterns, enabling architects and designers to bring their innovative visions to fruition. Additionally, steel formwork is reusable, thus making it a cost-effective option for theater construction projects. In contrast to traditional wooden formwork, which must be replaced after a single use, steel formwork can be employed multiple times, resulting in reduced material and labor expenses. Lastly, steel formwork facilitates a faster construction process. Its simple assembly and disassembly hasten the construction timeline, allowing theater projects to be completed within a shorter timeframe. In conclusion, steel formwork is a suitable selection for theater construction projects due to its strength, adaptability, flexibility, reusability, and efficiency. It offers numerous benefits that contribute to the successful and timely completion of theater construction projects.

- Q: How does steel formwork contribute to the overall durability of a structure?

- Steel formwork contributes to the overall durability of a structure in several ways. Firstly, steel formwork is highly resistant to wear and tear, which ensures that it can withstand the heavy loads and pressures exerted during the construction process. This durability prevents any deformations or damages to the formwork, ensuring that the structure is constructed accurately and without any compromise in its integrity. Additionally, steel formwork provides excellent dimensional stability, meaning that it retains its shape and size even under extreme conditions such as high temperatures or moisture exposure. This stability ensures that the concrete poured into the formwork maintains its desired shape and structural strength, resulting in a more durable and long-lasting structure. Furthermore, steel formwork offers superior strength and rigidity compared to other types of formwork materials. This strength enables it to support heavy concrete loads without any deformation or collapse, ensuring that the structure remains stable and secure. This characteristic is particularly important in the construction of large-scale structures such as bridges, high-rise buildings, or dams, where the formwork needs to bear significant loads for prolonged periods. Moreover, steel formwork is highly resistant to corrosion, which is a common cause of deterioration in construction materials. This resistance ensures that the formwork remains intact and unaffected by environmental factors such as moisture, chemicals, or exposure to the elements. As a result, the structure's overall durability is enhanced as the risk of corrosion-related damages is minimized. Lastly, steel formwork is reusable, which not only contributes to the sustainability of the construction process but also ensures cost-effectiveness. The ability to reuse the formwork multiple times reduces the need for additional materials and resources, resulting in less waste generation and lower construction costs. This factor also ensures that the formwork remains in good condition, as it can be properly maintained and inspected before each reuse, further enhancing its durability and longevity. In conclusion, steel formwork plays a crucial role in enhancing the overall durability of a structure. Its resistance to wear and tear, dimensional stability, strength, corrosion resistance, and reusability contribute to the construction of a robust and long-lasting structure, ensuring its integrity and minimizing the risk of structural failures or damages over time.

- Q: Can steel formwork be easily repaired in case of damage?

- Yes, steel formwork can be easily repaired in case of damage. Steel is a durable and malleable material, allowing for straightforward repairs such as welding, patching, or replacing damaged sections. Additionally, its strength and resilience make it less prone to damage compared to other formwork materials like wood or plastic.

- Q: How does steel formwork handle formwork alignment and leveling?

- The steel formwork system is a highly efficient and versatile solution that excels in the management of formwork alignment and leveling. It possesses numerous features and mechanisms that guarantee precise and accurate formwork placement. To begin with, the robustness and rigidity of steel formwork enable it to maintain its shape and dimensions throughout the pouring and curing of concrete. This inherent stability ensures that the formwork remains aligned and level during the entire construction process. Furthermore, steel formwork often incorporates adjustable components like screws, wedges, and clamps. These elements allow for fine-tuning of the formwork's position and elevation, facilitating precise alignment and leveling. By simply adjusting these components, workers can easily rectify any deviations and ensure perfect formwork alignment. Additionally, steel formwork systems frequently utilize integrated leveling systems. These systems typically consist of hydraulic jacks or mechanical devices that provide controlled and precise leveling. By utilizing these mechanisms, workers can effortlessly adjust the formwork's height and maintain a consistent level across the entire structure. Moreover, steel formwork possesses the ability to withstand significant loads and pressures exerted by the concrete during pouring. This strength enables it to resist any deformation or deflection, ensuring that the formwork remains aligned and level even under challenging conditions. In conclusion, the steel formwork system offers exceptional capabilities in managing formwork alignment and leveling. Its inherent stability, adjustable components, integrated leveling systems, and strength make it a reliable choice for maintaining the desired accuracy and precision during concrete construction projects.

- Q: How does steel formwork handle different concrete curing time requirements?

- Steel formwork is highly versatile and can easily accommodate different concrete curing time requirements. It offers excellent strength and durability, allowing for extended curing periods without compromising the structural integrity. Additionally, steel formwork provides a smooth and rigid surface that aids in achieving a consistent curing process. It can be easily assembled and disassembled, allowing for efficient adjustments to accommodate specific curing time requirements. Overall, steel formwork is a reliable choice that effectively handles different concrete curing time requirements.

Send your message to us

Steel-Frame corner link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords