Steel-Frame corner link for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

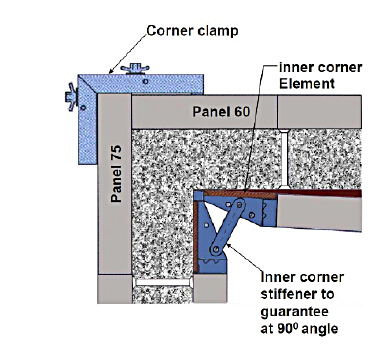

◆ The selection of panels.

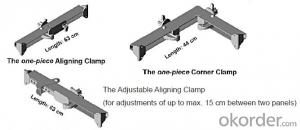

◆ Kinds of panel connectors.

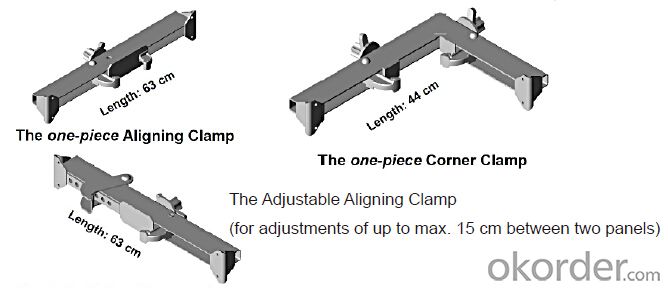

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: How does steel formwork contribute to the overall fire resistance of the structure?

- The fire resistance of a structure is primarily determined by the construction materials, including the type of steel used, the insulation and coating materials applied, and the overall design. Steel formwork, however, indirectly contributes to fire resistance by facilitating the construction of fire-resistant elements. It is commonly used in concrete construction to create walls, floors, and other structural elements. By providing a stable framework for pouring concrete, it enables the creation of fire-resistant concrete walls and floors that can withstand high temperatures and prevent the spread of fire. Steel formwork can also be used to create fire-rated concrete enclosures for important areas like stairwells and shafts. These enclosures help contain the fire and provide safe escape routes for occupants during emergencies. Additionally, steel formwork can incorporate fire-resistant materials such as insulation boards or coatings, which add another layer of fire protection to the resulting structure. Overall, although steel formwork itself does not directly contribute to fire resistance, it plays a crucial role in enabling the construction of fire-resistant elements and incorporating fire protection materials. This indirectly enhances the overall fire resistance and safety of the structure.

- Q: How does steel formwork affect the schedule of concrete pouring?

- Steel formwork can positively affect the schedule of concrete pouring by allowing for faster assembly and disassembly compared to traditional wooden formwork. This speed and efficiency help to accelerate the construction process, ultimately reducing the overall time required for concrete pouring activities. Additionally, steel formwork provides better dimensional accuracy and stability, enabling smoother and quicker concrete placement, which further contributes to meeting project deadlines.

- Q: Can steel formwork be used in underground structures?

- Underground structures can indeed utilize steel formwork. This material proves to be highly versatile and durable, capable of withstanding the demanding conditions underground. Its exceptional strength and stability make it ideal for constructing walls, columns, and slabs in subterranean spaces. One major advantage of steel formwork lies in its ability to resist the pressure exerted by the surrounding soil and water. Underground structures often encounter significant hydrostatic pressure, yet steel formwork remains resilient and free from deformation or collapse. This ensures the structure's safety and stability. Moreover, steel formwork is reusable, making it a cost-effective option for underground construction projects. Its robust nature allows for multiple uses, reducing the need for frequent replacements and lowering overall construction costs. Furthermore, steel formwork offers design flexibility, easily customizable to meet specific project requirements. It can be shaped and sized to create intricate geometries within underground structures. However, it is crucial to note that steel formwork necessitates proper surface treatment to safeguard against corrosion in the underground environment. Special coatings or galvanization can be applied to prevent rusting and extend the formwork's lifespan. In conclusion, steel formwork proves to be a suitable choice for underground structures due to its strength, durability, reusability, and design flexibility. It effectively withstands the challenges posed by the underground environment, guaranteeing long-term stability and safety for the structure.

- Q: Types of building templates? What is clear water template?

- Wood plywood (water templates): currently widely used in the solid wood plywood formwork, should promote the use of wood covered plywood. Commonly used in Guangdong area of Eucalyptus wood membrane.

- Q: Can steel formwork be customized for specific project requirements?

- Yes, steel formwork can be customized to meet specific project requirements. Steel formwork is highly versatile and can be fabricated to any shape, size, or design according to the project needs. It allows for flexibility in construction, ensuring that the formwork precisely fits the desired dimensions and complexities of the structure. Customization of steel formwork enables construction teams to optimize efficiency, accuracy, and safety during the concrete casting process.

- Q: What are the considerations when selecting the appropriate steel grade for formwork?

- When selecting the appropriate steel grade for formwork, there are several considerations that need to be taken into account. Firstly, the load-bearing capacity of the steel grade is of utmost importance. The steel should be able to withstand the weight and pressure exerted by the concrete and any additional loads that may be applied during construction. It should be able to maintain its structural integrity without any deformation or failure. Secondly, the corrosion resistance of the steel grade is crucial. As formwork is often subjected to moisture and chemicals present in concrete, it is essential to choose a steel grade that can resist corrosion. This will ensure the longevity and durability of the formwork, avoiding any potential safety hazards or costly repairs. Another consideration is the ease of handling and fabrication. The selected steel grade should be easy to cut, shape, and weld, allowing for efficient and accurate construction of formwork. It should also have good dimensional stability, ensuring that the formwork remains in the desired shape and size during use. The cost-effectiveness of the steel grade is also a significant factor. While it may be tempting to opt for a higher grade steel with superior properties, it is essential to evaluate the project requirements and choose a grade that offers the necessary performance at a reasonable cost. This will help to optimize the budget without compromising on the quality and functionality of the formwork. Lastly, compliance with industry standards and regulations should be considered. The selected steel grade should meet the relevant codes and specifications set by governing bodies to ensure that the formwork meets safety standards and can withstand the intended loads and environmental conditions. By taking these considerations into account, one can select an appropriate steel grade for formwork that ensures structural stability, durability, corrosion resistance, ease of handling, cost-effectiveness, and compliance with industry standards.

- Q: Is steel formwork suitable for all types of concrete structures?

- No, steel formwork may not be suitable for all types of concrete structures. While steel formwork is versatile and durable, it may not be cost-effective or practical for smaller projects or structures with complex designs. Additionally, certain conditions such as extreme temperatures, corrosive environments, or high-rise buildings may require alternative formwork systems. Therefore, the suitability of steel formwork depends on the specific project requirements and considerations.

- Q: Can steel formwork be used in hygienic or sterile environments?

- Steel formwork can be used in hygienic or sterile environments, but certain precautions need to be taken to ensure that the steel formwork does not compromise the cleanliness or sterility of the environment. Steel formwork is a durable and strong option for construction, and it is often used in a variety of applications including in hygienic or sterile environments such as hospitals, laboratories, or food processing facilities. However, it is important to note that steel is not inherently sterile and can harbor bacteria or other contaminants if not properly maintained. To ensure that steel formwork can be used in hygienic or sterile environments, several measures can be taken. Firstly, the steel formwork should be thoroughly cleaned and sanitized before being used in such environments. This can involve using approved cleaning agents and following specific cleaning protocols to remove any dirt, debris, or potential contaminants. Additionally, a protective coating or finish can be applied to the steel formwork to create a smooth and non-porous surface that is easier to clean and disinfect. This can help prevent the buildup of bacteria or other microorganisms on the formwork. Regular maintenance and inspections are also crucial to ensure that the steel formwork remains in a hygienic condition. Any signs of wear, damage, or corrosion should be promptly addressed and repaired to prevent the formation of cracks or crevices where bacteria can accumulate. It is worth noting that in some extremely sensitive sterile environments, other materials such as stainless steel or specialized plastics may be preferred over traditional steel formwork. These materials have properties that make them more resistant to corrosion, easier to clean, and more compatible with stringent hygiene or sterilization protocols. Ultimately, the suitability of steel formwork in hygienic or sterile environments will depend on the specific requirements and regulations of the environment in question. Proper cleaning, maintenance, and adherence to hygiene protocols are crucial to ensure that steel formwork can be used effectively in such environments without compromising cleanliness or sterility.

- Q: How does steel formwork handle different concrete surface finishing options?

- Steel formwork is highly versatile and capable of accommodating various concrete surface finishing options with ease. Its robust structure provides excellent support, allowing for smooth finishes like polished concrete or exposed aggregate. Additionally, steel formwork can incorporate intricate patterns or textures, enabling decorative finishes such as stamped or stenciled concrete. Moreover, the durability of steel formwork ensures consistent and accurate results, regardless of the desired surface finishing option.

- Q: Does steel formwork require any special expertise or training for installation?

- Yes, steel formwork generally requires special expertise or training for installation. The process involves understanding the structural requirements, proper handling and assembling of steel components, as well as ensuring the formwork's stability and safety. Expertise in steel construction and knowledge of formwork systems are usually necessary for a successful installation.

Send your message to us

Steel-Frame corner link for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords