Steel Billet Produced by Big Blast Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billet Produced by Big Blast Furnace

1.Structure of Steel Billet Produced by Big Blast Furnace

Steel Billet Produced by Big Blast Furnace Billet section of square, round, flat, rectangular and abnormity, etc Several, mainly related to shape of rolled products. Simple rolled section steel, choose cross section of square billet or rectangular billet. rolling The sector products such as flat steel, Angle steel, select the rectangular billet or slab. Had better profiled billet when production beams, channels, and in rolling process Lines and improve the yield. The raw material of round billet is the production of seamless tube.

2.Main Features of Steel Billet Produced by Big Blast Furnace

Steel Billet Manufactured by Blast Furnace without Boron section size should meet the requirements of rolling deformation and finished product quality, but also roll strength and biting condition of restrictions. General steel Billet section height H. And the roll diameter D The ratio of the ( namely H/D) Should be less than or equal to zero 0.5 . Length of steel billet by finishing temperature, Rolling time and the length of the product Or times ruler. When heated too long accident prone to bump the furnace wall of steel, too short, furnace bottom utilization rate is not high, influence the heating furnace production. For the production Choose a variety of steel and steel billet, should consider the affinities of billet, as far as possible in order to improve the productivity of the roughing mill, simplify the stock management of workshop.

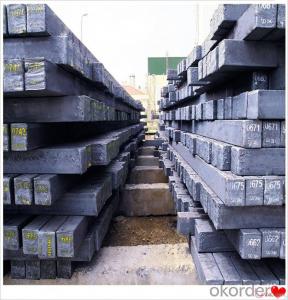

3. Steel Billet Produced by Big Blast Furnace Images

4. Steel Billet Produced by Big Blast Furnace Specification

Steel Billet Manufactured by Blast Furnace without Boron rolled steel, after processing can be used for mechanical parts, forging parts, processing all kinds of steel, steel Q345B channel steel, wire rod is the role of the billet. Steel billet is used in the production of semi-finished products, generally cannot be used directly for the society. Steel billets and steel are strictly divided into standard, cannot decide to whether the business enterprise of the final product, and according to unified standards to perform the whole society. Typically, billet and the steel is relatively easy to distinguish, but for some steel billet, and have the same specification and same steel purposes (such as rolling tube billet), whether can be used for other industries, whether through steel processing process, whether through a finished product rolling mill processing to distinguish

The classification of the Bloom Mainly from the shape is divided into two kinds: Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate. Bloom: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod.

Bloom material standard The thickness range: 150-240 - mm + / - 5 mm The width of the range: 880-1530 - mm + / - 20 mm Length range: 3700-10000 - mm + / - 500 - mm Cross-sectional size: 64 * 64 ; 82 * 82 ; 98 * 98 ; 124 * 124 ; 120 * 150 ; 152 * 164 ; 152 * 170 mm Length: 9000 mm The section of tolerance: Bloom: 1.0 + / - 2.0-1.0 + / - 1.0 mm The slab width: + / - 2.0 MM ; Thickness: + / - 3.0 MM

5.FAQ of Steel Billet Produced by Big Blast Furnace

We have organized several common questions for our clients,may help you sincerely:

①How is the standard you can meet?

For the chemical composition, according to the Chinese standard of GB700-88, and the section size according to the standard of YB2011-83,

②How is the chemical standard?

2

C%

Mn%

Si% S% P% Q215

A 0.09~0.15 0.25~0.55 ≤0.30 ≤0.050 ≤0.045 B 0.09~0.15 0.25~0.55 ≤0.30 ≤0.045 ≤0.045 Q235

A

0.14~0.22 0.30~0.65 ≤0.30 ≤0.050 ≤0.045 B 0.12~0.20 0.30~0.70 ≤0.30 ≤0.045 ≤0.045 C ≤0.18 0.35~0.80 ≤0.30 ≤0.040 ≤0.040 D

≤0.17

0.35~0.80

≤0.30

≤0.035

≤0.035

③How is the packaging and delivery?

Exporting Package with the steel material cover and the delivery term is based on the project.

- Q: How are steel billets used in the production of industrial boilers?

- Steel billets are an essential component in the production of industrial boilers. These billets, which are typically made of high-quality steel, serve as the raw material for fabricating the various parts and components of a boiler. The manufacturing process starts with the steel billets being heated to a specific temperature, which allows them to be easily shaped and formed. They are then passed through a series of rolling mills, where they are transformed into different shapes and sizes, such as plates, bars, or tubes, depending on the specific requirements of the boiler design. These billets are then further processed to create the necessary boiler components. For example, plates are cut and shaped to form the boiler shell, which serves as the main structure of the boiler. Bars are used to create the boiler tubes, which are responsible for transferring heat from the combustion chamber to the water. Additionally, other parts such as flanges, fittings, and supports are also made from steel billets. The quality and strength of the steel billets used in the production of industrial boilers are crucial factors in ensuring the durability and efficiency of the final product. Steel billets with high tensile strength and excellent heat resistance properties are preferred, as they can withstand the high pressures and temperatures associated with boiler operations. In summary, steel billets play a critical role in the production of industrial boilers by providing the raw material necessary for fabricating the various components. Their versatility, strength, and durability make them an ideal choice for creating the robust and reliable boilers required for a wide range of industrial applications.

- Q: What are the different methods of steel billet surface painting?

- There are several methods of steel billet surface painting, including spray painting, powder coating, electrostatic coating, and dip coating. Spray painting involves using compressed air or a sprayer to apply a liquid paint to the surface of the billet. Powder coating involves applying a dry powder to the surface, which is then heated to create a durable and protective coating. Electrostatic coating uses an electric charge to attract the paint particles to the billet surface, creating an even and uniform coating. Dip coating involves immersing the billet in a tank of paint, allowing the paint to adhere to the surface. Each method has its own advantages and is chosen based on factors such as the desired finish, cost, and environmental considerations.

- Q: What are the potential applications of steel billets in the aerospace industry?

- Steel billets have several potential applications in the aerospace industry. They can be used for the manufacturing of various components such as engine parts, landing gear components, and structural elements. The high strength and durability of steel billets make them suitable for ensuring the structural integrity and safety of aircraft. Additionally, their excellent heat resistance properties make them ideal for applications in the aerospace industry where high temperatures are encountered, such as in jet engines.

- Q: What are the cost implications of using steel billets in manufacturing?

- The cost implications of using steel billets in manufacturing can vary depending on several factors. Firstly, the price of steel billets themselves can fluctuate due to market conditions and supply and demand. Additionally, the cost of transportation and logistics to acquire and transport the billets to the manufacturing facility can impact overall expenses. Moreover, the processing and fabrication techniques required to convert the billets into finished products may incur additional costs, such as labor, energy, and equipment expenses. Furthermore, the quality and characteristics of the steel billets, including their composition, size, and surface finish, can also influence costs. Ultimately, careful consideration of these factors is necessary to assess the cost implications accurately.

- Q: What is the difference between hot-rolled and cold-rolled steel billets?

- Hot-rolled and cold-rolled steel billets are both types of steel that undergo different manufacturing processes, resulting in distinct characteristics and properties. Hot-rolled steel billets are produced by heating the steel to a high temperature and then rolling it while it is still hot. This process allows for the steel to be easily shaped and formed into various sizes and shapes. Hot-rolling also results in a rough surface finish and a scaled outer layer due to the exposure to high temperatures. The hot-rolled steel billets generally have a larger grain structure, which can lead to a less precise and uniform final product. However, the hot-rolled steel billets tend to have improved mechanical properties, such as higher strength and toughness, making them suitable for applications where strength is crucial but surface finish is not a priority. On the other hand, cold-rolled steel billets are produced by cooling the steel to a low temperature and then rolling it at room temperature. This process allows for tighter dimensional tolerances and a smoother surface finish compared to hot-rolled steel billets. Cold-rolling also results in a more refined grain structure, which enhances the overall strength, hardness, and durability of the steel. Cold-rolled steel billets are commonly used in applications where precise dimensions, surface finish, and uniformity are required, such as in the automotive, construction, and appliance industries. In summary, the main difference between hot-rolled and cold-rolled steel billets lies in the manufacturing processes and the resulting properties. Hot-rolled steel billets are formed at high temperatures, resulting in a rough surface finish and larger grain structure, while cold-rolled steel billets are formed at room temperature, leading to tighter dimensional tolerances, smoother surface finish, and a more refined grain structure. The choice between hot-rolled and cold-rolled steel billets depends on the specific requirements and applications, with hot-rolled steel billets being preferred for their superior strength and cold-rolled steel billets for their precise dimensions and surface finish.

- Q: Use medium frequency furnace (1 million 500 thousand volt ampere) to produce 1 ton cast steel blank, how much kilowatt hour is consumed?

- This depends on the intermediate frequency furnace voltage level and inverter efficiency, the general high voltage will save power, generally 550-700 range, details can refer to wcdlsb site medium frequency furnace data

- Q: What are the potential applications of steel billets in the chemical industry?

- Due to their unique properties and versatility, steel billets have numerous potential applications in the chemical industry. One primary use of steel billets in the chemical industry involves their utilization in the production of various types of equipment and machinery. Steel billets can be shaped and forged into different forms, such as pipes, tanks, valves, and fittings, which are crucial for the handling and storage of chemicals. These components need to withstand harsh conditions, including high temperatures, pressures, and corrosive environments, thereby making steel billets an ideal material choice. Additionally, steel billets can be employed in the construction of chemical plants and facilities. They provide exceptional structural support, ensuring the stability and integrity of the buildings. Steel billets are often used in fabricating beams, columns, and other load-bearing elements, providing strength and durability to withstand the chemical processes occurring within the plant. Another potential application of steel billets in the chemical industry pertains to the manufacturing of reaction vessels and reactors. These vessels are utilized for chemical reactions, such as synthesis, distillation, and purification processes. Steel billets can be machined and formed into the desired shape, allowing for the creation of robust and reliable vessels that can handle the high pressures and temperatures often required in chemical reactions. Furthermore, steel billets can be utilized in the production of catalysts used in various chemical processes. Catalysts are substances that expedite chemical reactions without being consumed in the process. Steel billets can serve as a base material for catalysts, providing a stable and durable support structure for the active catalytic components. Moreover, steel billets can be employed in the construction of storage tanks and containers for the transportation and storage of chemicals. Steel billets offer exceptional resistance to corrosion and can be easily welded and fabricated into large containers, ensuring the safe and secure storage of hazardous chemicals. In summary, steel billets possess vast potential applications in the chemical industry. Their strength, durability, and resistance to corrosion make them indispensable materials for various chemical processes and operations, encompassing equipment fabrication, construction projects, catalyst manufacturing, and storage solutions.

- Q: How are steel billets used in the production of bars and rods?

- Steel billets are used as a raw material in the production of bars and rods. They are first heated and then passed through a series of rolling mills to be shaped into the desired form. This process increases the strength and durability of the steel, making it suitable for various applications such as construction, manufacturing, and automotive industries.

- Q: Can steel billets be extruded into different shapes?

- Yes, steel billets can be extruded into different shapes. Extrusion is a metalworking process where a material, in this case, a steel billet, is forced through a die to create a desired shape. The billet is heated to a specific temperature to make it malleable and then pushed through the die using a hydraulic or mechanical press. This process allows for the creation of a wide range of shapes, such as rods, bars, tubes, profiles, and even complex geometries. Extrusion is commonly used in the manufacturing industry to produce various steel products for construction, automotive, aerospace, and other applications.

- Q: Can steel billets be used in the production of industrial equipment?

- Yes, steel billets can be used in the production of industrial equipment. Steel billets are the raw material that can be further processed and shaped into various forms such as plates, sheets, rods, and bars. These processed steel products are commonly used in the manufacturing of industrial equipment due to their strength, durability, and suitability for machining and welding processes.

Send your message to us

Steel Billet Produced by Big Blast Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords