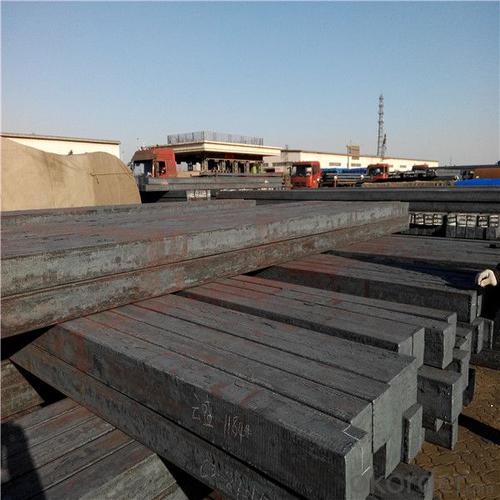

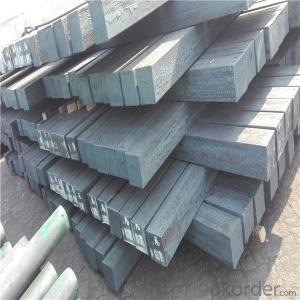

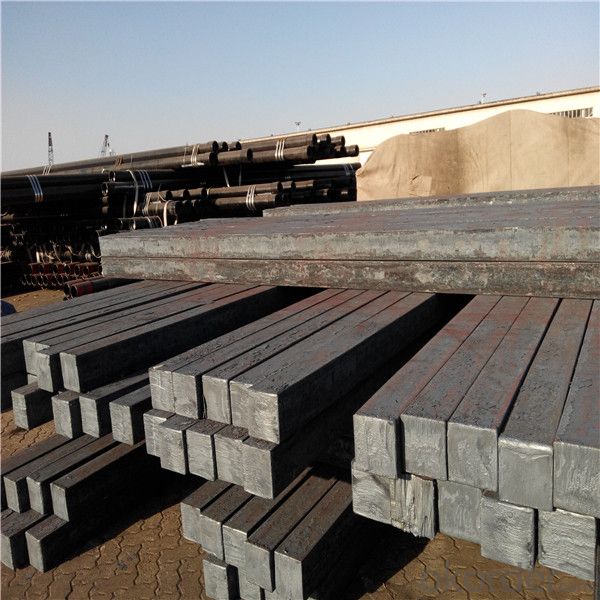

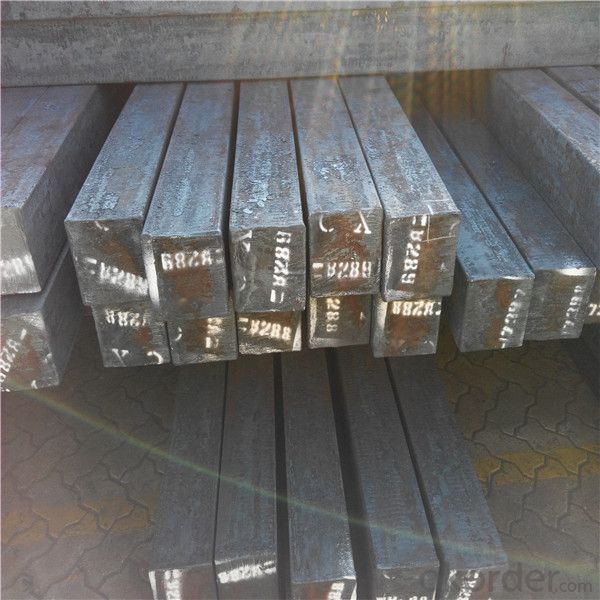

Chrome alloy square steel billet made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

(ingot) by cogging or breakdown of semifinished products, is the raw material of all kinds of steel mill.

Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the

shape of rolled products.

Used for the plant, the bridge,shipment building high rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What is the role of steel billets in the construction of stadiums and arenas?

- Steel billets play a crucial role in the construction of stadiums and arenas. These billets, which are essentially semi-finished steel products, serve as the raw material for various structural components used in the construction process. One of the primary applications of steel billets in stadium and arena construction is for the fabrication of steel beams and columns. These structural elements provide the necessary support and stability to the overall structure. Steel billets are first heated and then passed through rolling mills to acquire the desired shape and size required for these beams and columns. Moreover, steel billets are also used in the production of steel reinforcing bars, commonly known as rebars. These rebars are used to reinforce the concrete structures within stadiums and arenas, such as foundations, walls, and floors. The combination of steel and concrete enhances the structural integrity and load-bearing capacity of these structures, making them capable of withstanding heavy loads, vibrations, and external forces. Additionally, steel billets are utilized in the construction of roof trusses and frames, which provide support for the stadium or arena's roofing system. These steel components offer the necessary strength and durability to withstand the weight of the roof, while also ensuring the overall stability of the structure. Furthermore, steel billets are employed in the production of seating structures, staircases, handrails, and other architectural elements within stadiums and arenas. These components not only contribute to the overall aesthetics of the venue but also provide safety and comfort to spectators. In summary, steel billets are indispensable in the construction of stadiums and arenas. They are transformed into various structural and architectural components that provide strength, stability, and durability to the overall structure. By utilizing steel billets, stadiums and arenas can be built to withstand the demands of large crowds, harsh weather conditions, and the test of time.

- Q: What are the safety precautions in handling steel billets?

- Handling steel billets requires adherence to specific safety precautions to prevent accidents and injuries. Some of the key safety precautions include: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, steel-toed boots, and protective clothing, to protect against potential hazards like sharp edges, falling objects, and flying debris. 2. Lifting Techniques: Use proper lifting techniques, such as bending the knees and lifting with the legs, to avoid strains or injuries to the back. If the billets are too heavy to lift manually, use mechanical lifting equipment like cranes or forklifts. 3. Secure Storage: Ensure that steel billets are stored in a secure and stable manner to prevent them from toppling or rolling, which can cause injuries or damage to equipment and infrastructure. Utilize appropriate storage racks, bins, or pallets to keep the billets organized and secure. 4. Handling Tools: Use suitable tools like lifting hooks, clamps, or tongs to handle steel billets safely. Avoid using your hands or body to move or reposition the billets, as this can lead to pinching, crushing, or cutting injuries. 5. Clear and Well-Defined Work Area: Maintain a clear and well-defined work area around the steel billets to prevent tripping hazards. Remove any obstructions or debris that could cause slips, trips, or falls. 6. Communication and Training: Ensure that all personnel involved in handling steel billets are adequately trained in safe handling procedures and are aware of potential hazards. Establish clear communication channels to coordinate movements and actions, especially when using machinery or working in teams. 7. Inspection and Maintenance: Regularly inspect the condition of the steel billets, lifting equipment, and storage racks to identify any potential safety issues. Promptly address any defects, damages, or wear and tear to prevent accidents. 8. Emergency Procedures: Establish emergency procedures and ensure that all personnel are aware of them. This includes procedures for handling accidents, injuries, spills, or other emergencies that may occur during the handling of steel billets. By following these safety precautions, the risk of accidents and injuries can be minimized, creating a safer working environment for all individuals involved in handling steel billets.

- Q: What are the potential applications of steel billets in the medical aftermarket?

- The medical aftermarket offers a wide range of potential applications for steel billets. One important application is the manufacture of surgical instruments, such as scalpels, forceps, scissors, and orthopedic implants. Steel billets are capable of producing high-quality and durable surgical instruments due to the strength and corrosion resistance of steel. Furthermore, steel billets are also useful in the production of medical equipment and devices. For instance, they can be used to create components for X-ray machines, CT scanners, and MRI machines. The excellent conductivity and high strength-to-weight ratio of steel make it a suitable choice for these demanding applications. In addition, steel billets can be utilized in the manufacturing of medical furniture and fixtures. Steel is commonly employed in the construction of hospital beds, examination tables, and cabinets due to its durability and ease of maintenance. Steel billets can provide the necessary raw material for the production of these essential medical items. Moreover, steel billets can also be employed in the fabrication of prosthetics and orthotics. These devices often require materials that are both strong and lightweight to ensure proper functionality and comfort for patients. Steel billets can be processed into various shapes and sizes to create prosthetic limbs, braces, and other orthopedic devices. In summary, the diverse and crucial potential applications of steel billets in the medical aftermarket cannot be underestimated. From surgical instruments to medical equipment, furniture, and prosthetics, steel billets possess the necessary qualities of strength, durability, and corrosion resistance to meet the demanding requirements of the medical industry.

- Q: What is the standard size of a steel billet?

- The standard size of a steel billet can vary depending on the specific requirements and industry standards. However, in general, steel billets are typically rectangular in shape and have dimensions ranging from 100mm x 100mm to 200mm x 200mm. The length of a steel billet can also vary but is commonly around 6 meters. It is important to note that these dimensions are not fixed and can be customized based on the intended use and manufacturing process.

- Q: How do steel billets contribute to the infrastructure development?

- Steel billets are a crucial component in infrastructure development as they serve as the raw material for manufacturing various steel products used in construction. These billets are used to produce reinforcement bars, beams, columns, and other structural elements that provide strength and stability to buildings, bridges, roads, and other infrastructure projects. By providing a strong and durable foundation, steel billets contribute significantly to the overall safety and longevity of infrastructure, promoting sustainable development and economic growth.

- Q: What are the potential applications of steel billets in the agricultural sector?

- Steel billets have a wide range of potential applications in the agricultural sector. One of the primary uses of steel billets in agriculture is for the manufacturing of farm equipment and machinery. Steel billets can be used to produce durable and sturdy components such as plows, cultivators, and seeders, which are essential for tilling the soil, planting seeds, and maintaining agricultural land. Steel billets can also be utilized in the construction of storage structures on farms. Steel is known for its strength and durability, making it an ideal material for constructing grain silos, barns, and sheds. These structures provide farmers with a reliable and long-lasting solution for storing crops, livestock, and equipment. In addition, steel billets can be used to fabricate fences and gates for animal enclosures. Steel fences offer superior strength and security, ensuring the safety of farm animals and preventing them from wandering off. These fences are also resistant to corrosion and are capable of withstanding harsh weather conditions. Furthermore, steel billets can be employed in the construction of irrigation systems and water management infrastructure on farms. Steel pipes and fittings are commonly used to transport water from a source to the fields, ensuring proper irrigation and efficient water distribution. Lastly, steel billets can be utilized in the production of machinery used for processing agricultural products. For example, steel components can be used to manufacture grain mills, threshers, and sorting machines, which aid in the processing and packaging of crops. Overall, the potential applications of steel billets in the agricultural sector are vast and varied. From farm equipment and storage structures to fencing and irrigation systems, steel billets play a crucial role in enhancing efficiency, durability, and productivity in agriculture.

- Q: What is the global production and consumption of steel billets?

- The global production and consumption of steel billets is significant and plays a crucial role in the construction and manufacturing sectors worldwide. Steel billets are semi-finished products that are used as raw material for the production of various steel products. In terms of production, several countries are major players in steel billet manufacturing. China, which is the largest producer of steel globally, accounts for a significant portion of the global steel billet production. Other prominent producers include India, Japan, Russia, the United States, and Turkey. These countries have well-established steel industries and infrastructure to support large-scale production. The consumption of steel billets is driven by the demand for steel products across various sectors. Construction and infrastructure development are the primary drivers of steel billet consumption, as steel is widely used in the construction of buildings, bridges, roads, and other structures. The automotive industry is another major consumer of steel billets, as they are used for manufacturing automobile parts and components. It is challenging to provide an exact figure for the global production and consumption of steel billets due to the constantly changing market dynamics and varying industry reports. However, it is estimated that global steel production exceeded 1.8 billion metric tons in 2020, with a substantial portion of this production being in the form of steel billets. The consumption of steel billets is closely linked to the overall steel demand, which is influenced by economic growth, infrastructure development, industrial activity, and construction projects worldwide. Overall, the global production and consumption of steel billets are significant, reflecting the importance of steel as a crucial material in various industries. The continuous growth in infrastructure development and industrialization across the globe is expected to further drive the production and consumption of steel billets in the coming years.

- Q: What are the potential applications of steel billets in the oil and gas aftermarket?

- Steel billets have a wide range of potential applications in the oil and gas aftermarket. Firstly, steel billets can be used for the manufacturing of various components in the oil and gas industry, such as valves, flanges, and fittings. These components are essential for the operation and maintenance of pipelines, refineries, and drilling facilities. Additionally, steel billets can be used for the production of seamless pipes, which are crucial for transporting oil and gas over long distances. Seamless pipes made from steel billets offer high strength, durability, and resistance to corrosion, making them suitable for the harsh conditions often encountered in the oil and gas industry. Furthermore, steel billets can be utilized in the manufacturing of downhole tools and equipment. These tools are used during drilling operations to extract oil and gas from the ground. Steel billets provide the necessary strength and toughness required to withstand the extreme pressures and temperatures encountered in downhole environments. Moreover, steel billets can be used for the fabrication of storage tanks and vessels used in the oil and gas industry. These tanks are used for storing crude oil, refined products, and natural gas. Steel billets offer excellent weldability and structural integrity, ensuring the reliability and safety of storage facilities. Furthermore, steel billets can be used for the construction of offshore platforms and structures. These platforms are used for drilling, production, and processing activities in offshore oil and gas fields. Steel billets are favored in this application due to their high strength, corrosion resistance, and ability to withstand the harsh marine environment. In summary, the potential applications of steel billets in the oil and gas aftermarket are extensive. From the manufacturing of components, seamless pipes, and downhole tools to the fabrication of storage tanks and offshore platforms, steel billets play a vital role in supporting the operations of the oil and gas industry.

- Q: 20 what is the difference between manganese silicon steel billet and Q235 billet?

- 20 manganese silicon steel billet for high strength steel,Q235 billet is almost the most common steel, requiring the lowest.

- Q: What are the different types of mechanical property testing methods for steel billets?

- Some different types of mechanical property testing methods for steel billets include tensile testing, hardness testing, impact testing, and fatigue testing. Tensile testing measures the strength and ductility of the material by applying a pulling force until it breaks. Hardness testing measures the resistance of the material to penetration or indentation. Impact testing evaluates the material's ability to absorb energy under high rates of loading. Fatigue testing assesses the material's resistance to failure under cyclic loading conditions.

Send your message to us

Chrome alloy square steel billet made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords