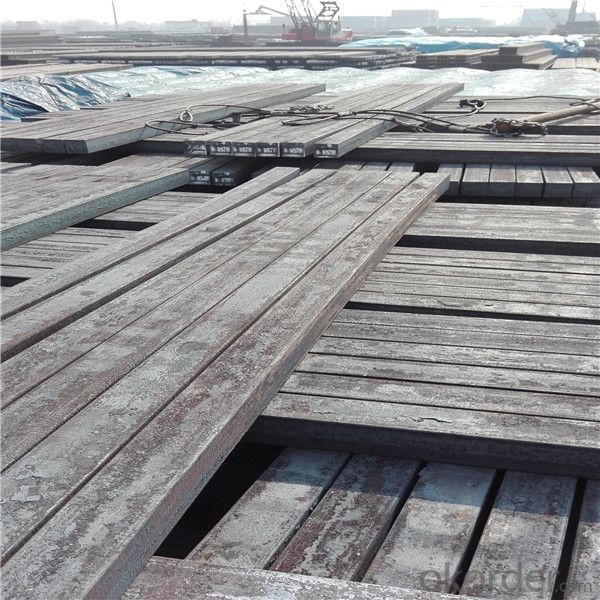

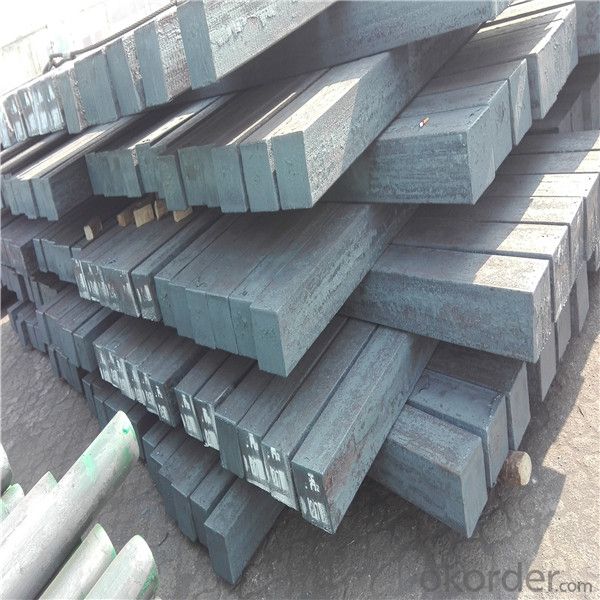

Steel Billet made in China with High quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17642 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet :

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular

and abnormity of several kinds of, mainly related to the shape of rolled products.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more

functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping

and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores,

or used for different applications. The unformed billets, however, can be used in striking currency such as coins and

as reserves, similar to gold bars.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What is the role of steel billets in the manufacturing of structural steel bridges?

- Steel billets play a crucial role in the manufacturing of structural steel bridges. These billets are essentially semi-finished products that serve as the raw material for the production of various steel products, including structural steel bridges. The process begins with steel billets being heated and then passed through a series of rolling mills to shape them into the desired form. This rolling process ensures that the billets are transformed into long, slender sections that can be utilized in the construction of bridges. Once the steel billets have been rolled into the appropriate shapes, they are then further processed and fabricated to create the necessary components for structural steel bridges. These components can include beams, columns, girders, and other critical elements that provide strength, stability, and load-bearing capabilities to the bridge structure. The use of steel billets in the manufacturing of structural steel bridges offers several advantages. Firstly, steel is known for its exceptional strength-to-weight ratio, making it an ideal material for constructing bridges that can withstand heavy loads while remaining relatively lightweight. The versatility of steel also allows for the creation of complex bridge designs, accommodating different architectural and engineering requirements. Additionally, steel billets are highly durable and resistant to environmental factors such as corrosion, which is crucial for ensuring the long-term integrity and safety of the bridge structure. This durability contributes to the overall longevity of the bridge, reducing maintenance and replacement costs over time. In summary, steel billets serve as the foundation for the production of structural steel bridges. Through the rolling and fabrication processes, these billets are transformed into the various components that make up the bridge structure, providing strength, stability, and durability. The use of steel billets enables the construction of bridges that can withstand heavy loads, remain lightweight, and withstand environmental factors, ensuring the long-term integrity and safety of the bridge.

- Q: What are the common sizes of steel billets?

- The sizes of steel billets can differ depending on the specific industry and application. However, there are various standard sizes that are frequently utilized. In the construction sector, steel billets commonly measure between 100mm x 100mm and 200mm x 200mm. These sizes are often employed in the fabrication of structural steel, such as beams, columns, and other load-bearing elements. For the production of automotive parts, the usual sizes of steel billets typically range from 150mm x 150mm to 250mm x 250mm. These sizes are commonly employed in forging and machining processes to manufacture components like crankshafts, connecting rods, and gears. In the oil and gas industry, larger steel billets are often necessary for manufacturing pipes and tubes. The typical sizes for this purpose range from 350mm x 350mm to 500mm x 500mm. These larger billets enable the production of seamless pipes capable of withstanding high-pressure environments. It should be noted that these are only general sizes and can vary depending on specific project requirements and regional standards. Additionally, customized sizes can also be produced based on the customer's requirements.

- Q: How are steel billets used in the production of industrial machinery?

- Steel billets are used in the production of industrial machinery as starting materials for various components, such as gears, shafts, and structural parts. These billets are heated, shaped, and machined to meet the specific requirements of the machinery, ensuring strength, durability, and precision in the final product.

- Q: How are steel billets reheated before rolling or forging?

- Steel billets are reheated before rolling or forging through a process known as billet heating. This process involves subjecting the billets to high temperatures to make them more malleable and easier to shape. There are several methods commonly used for billet heating, including: 1. Furnaces: The most common method of reheating steel billets is through the use of furnaces. These furnaces are typically gas-fired and can reach temperatures of up to 1,200 degrees Celsius. The billets are loaded into the furnace and heated for a specific period of time to achieve the desired temperature. The furnace provides a controlled environment, allowing for even heating and uniformity. 2. Induction heating: Another method used for reheating steel billets is induction heating. This process utilizes electromagnetic induction to heat the billets. An alternating current is passed through a copper coil, creating a magnetic field. The billets are then placed inside the coil, and the magnetic field induces eddy currents within the billets, generating heat. Induction heating offers precise temperature control and rapid heating rates, making it suitable for high-speed production. 3. Electric resistance heating: Electric resistance heating is another technique employed for reheating steel billets. This method involves passing an electric current through the billets, causing them to heat up due to the resistance encountered. Electric resistance heating can be achieved using various types of heating elements, such as graphite electrodes or resistance heating wires. This method offers precise temperature control and is commonly used for smaller-scale operations. Regardless of the heating method used, it is essential to carefully control the temperature and heating time to ensure the billets reach the optimal temperature for rolling or forging. The reheating process allows the steel to become more pliable, reducing its hardness and increasing its ductility, making it easier to shape and form into the desired end product.

- Q: How are steel billets coated or painted?

- Steel billets can be coated or painted through several methods. One common technique is hot-dip galvanizing, where the billets are immersed in a bath of molten zinc. This process forms a protective zinc coating on the surface of the steel, preventing corrosion. Another method is electroplating, which involves the deposition of a thin layer of metal, such as zinc or nickel, onto the billets using an electric current. Additionally, steel billets can be painted using various coating systems, such as powder coating or liquid paint, to provide a decorative finish or additional protection against rust and environmental factors.

- Q: How do steel billets contribute to the manufacturing of sports equipment?

- Steel billets contribute to the manufacturing of sports equipment in various ways. Firstly, steel billets are the raw material used to produce steel bars and rods, which are then used to create the frame and structure of sports equipment such as golf clubs, tennis rackets, and hockey sticks. The strength and durability of steel make it an ideal material for these applications, as it can withstand the high impact forces and stresses that occur during sports activities. Additionally, steel billets are also used to manufacture components of sports equipment such as weights, dumbbells, and barbells. These components require a high density material that can handle heavy loads, and steel provides the necessary strength and stability. Furthermore, steel billets are used in the production of sports equipment accessories like ball bearings, springs, and fasteners. These small yet crucial components play a vital role in the overall performance and functionality of sports equipment. Steel's excellent corrosion resistance and ability to withstand extreme conditions make it a preferred choice, ensuring long-lasting and reliable performance. Moreover, steel billets contribute to the manufacturing of sports equipment by enabling the production of high-quality and precision-made parts. Steel's malleability and formability allow it to be shaped into various complex designs and configurations, ensuring that sports equipment meets the specific requirements of athletes and performs optimally. In summary, steel billets are an indispensable component in the manufacturing of sports equipment. Their strength, durability, versatility, and formability make them an ideal material for producing frames, components, and accessories that enhance the performance and longevity of sports equipment.

- Q: What are the different types of steel billet surface treatment defects?

- During the manufacturing process, various defects can arise in the surface treatment of steel billets. The presence of these defects can have a negative impact on the quality and appearance of the billets, making it essential to detect and resolve them in order to guarantee the overall performance of the end product. 1. One common defect is scale, which occurs when the steel billet is exposed to high temperatures. This results in the formation of an oxide layer on the surface, adversely affecting the adhesion of coatings or paints. 2. Inclusions are another type of defect that can be found on the surface of the steel billet. These inclusions are non-metallic particles or impurities that may originate from inadequate cleaning or improper handling during the manufacturing process. They have the potential to undermine the mechanical properties of the steel, leading to an overall reduction in performance. 3. Decarburization is a defect that arises when the carbon content in the outer layer of the steel billet is lost due to exposure to high temperatures or a lack of protective atmosphere. This loss of carbon can result in decreased hardness and strength in the affected area. 4. Pitting is a localized defect characterized by the presence of small cavities or pits on the surface of the steel billet. It can be caused by impurities or exposure to corrosive environments. Pitting has the potential to compromise the structural integrity of the billet and make it more susceptible to corrosion. 5. Surface cracks may occur on the steel billet due to factors such as thermal stress, improper handling, or inadequate cooling. These cracks weaken the billet and increase the risk of failure during subsequent processing or use. 6. Surface roughness refers to an uneven or irregular texture on the surface of the steel billet. It can be caused by factors such as improper machining, inadequate cleaning, or the presence of scale or inclusions. Surface roughness affects the appearance of the billet and can impact its performance in certain applications. In conclusion, it is crucial to identify and resolve these surface treatment defects to ensure the quality and reliability of steel billets. Employing proper manufacturing processes, including thorough cleaning, protective atmospheres, and appropriate handling, is key to minimizing the occurrence of these defects and ensuring optimal performance of the final product.

- Q: What are the main factors affecting the corrosion resistance of steel billets?

- The main factors affecting the corrosion resistance of steel billets are the composition of the steel, the presence of impurities, the surface condition, and the surrounding environment. Firstly, the composition of the steel plays a crucial role in its corrosion resistance. Stainless steels, for example, contain a high amount of chromium and other alloying elements that form a protective oxide layer on the surface, thereby providing excellent corrosion resistance. On the other hand, carbon steels have a lower resistance to corrosion due to their higher carbon content and lack of alloying elements. Secondly, the presence of impurities in the steel can significantly impact its corrosion resistance. Inclusions, such as sulfur, phosphorous, and non-metallic inclusions, can act as initiation sites for corrosion, leading to localized corrosion and reduced overall resistance. Therefore, controlling the presence and distribution of impurities during the production of steel billets is essential for enhancing corrosion resistance. Moreover, the surface condition of the steel billets plays a vital role in their corrosion resistance. A smooth and clean surface promotes the formation of a protective oxide layer that acts as a barrier against corrosive substances. Conversely, rough or contaminated surfaces can lead to accelerated corrosion due to increased surface area and potential for localized corrosion. Lastly, the surrounding environment greatly influences the corrosion resistance of steel billets. Factors such as humidity, temperature, pH, and the presence of corrosive substances like acids, salts, or pollutants can accelerate corrosion. For instance, steel billets exposed to high humidity or corrosive chemicals are more susceptible to corrosion than those in dry or less corrosive environments. In summary, the corrosion resistance of steel billets is influenced by the composition of the steel, the presence of impurities, the surface condition, and the surrounding environment. It is crucial to consider these factors during the production and handling of steel billets to ensure their long-term durability and resistance to corrosion.

- Q: How are steel billets used in the manufacturing of construction scaffolding?

- Steel billets are an essential raw material used in the manufacturing of construction scaffolding. These billets are initially heated and then passed through a series of rolling mills to achieve the desired shape and size for scaffolding components. Once the steel billets are rolled into the required shape, they are further processed to create various scaffolding parts, such as tubes, couplers, frames, and planks. These parts are then assembled to form the scaffolding structure that provides a safe and sturdy platform for workers to perform tasks at elevated heights during construction projects. The use of steel billets in the manufacturing of construction scaffolding offers several advantages. Firstly, steel is known for its exceptional strength and durability, making it an ideal material for scaffolding. Additionally, steel is resistant to corrosion and can withstand harsh weather conditions, ensuring the scaffolding remains reliable and safe throughout the construction process. Moreover, steel scaffolding is highly versatile and can be easily customized to fit different project requirements. The use of steel billets allows manufacturers to create scaffolding components of various sizes, shapes, and configurations to accommodate different construction needs. In conclusion, steel billets play a crucial role in the manufacturing of construction scaffolding. By utilizing these raw materials, scaffolding manufacturers can produce durable, reliable, and customizable scaffolding structures that enhance safety and efficiency on construction sites.

- Q: How are steel billets used in the automotive industry?

- The automotive industry heavily relies on steel billets, which are indispensable due to their strength, durability, and versatility. These billets are extensively used to manufacture a wide range of automobile parts, including chassis, engine components, suspension systems, and body panels. Among the many applications of steel billets in the automotive industry, crankshafts stand out as a prime example. Crankshafts play a vital role in converting the reciprocating motion of pistons into rotational motion, and they must endure immense stress and pressure. Steel billets possess the necessary strength and resilience to meet these demanding requirements. Similarly, steel billets find application in the production of camshafts, which control the operation of an engine's valves. Camshafts must exhibit high precision and durability to withstand continuous mechanical stresses, and steel billets offer the mechanical properties required for reliability. Furthermore, steel billets are commonly employed in manufacturing various suspension components like control arms and axle shafts. These components must withstand heavy loads and shocks while maintaining their structural integrity, making steel billets an ideal material choice. In addition, steel billets are utilized in the manufacturing of body panels, including doors, hoods, and fenders. These parts necessitate high strength to ensure passenger safety and withstand impacts, and steel billets provide the required strength while also being cost-effective. Moreover, transmission components such as gears and shafts are also produced using steel billets. These parts demand high strength, wear resistance, and dimensional accuracy, all of which are provided by steel billets. In summary, steel billets play a vital role in the automotive industry by enabling the production of various components and parts that require exceptional strength, durability, and precision.

Send your message to us

Steel Billet made in China with High quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17642 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords