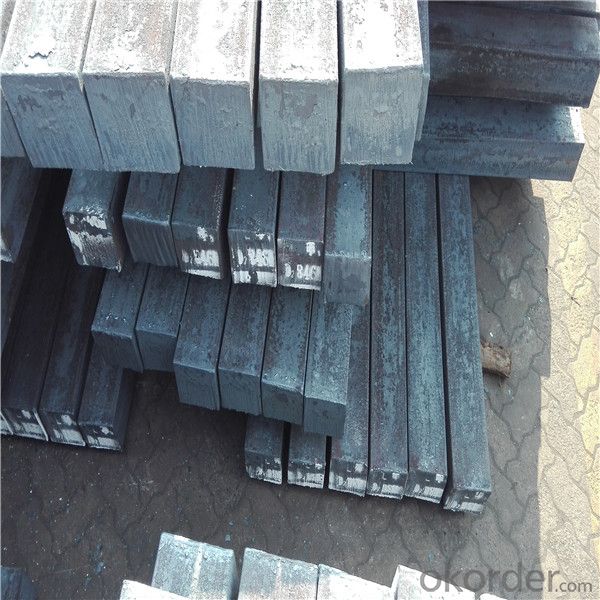

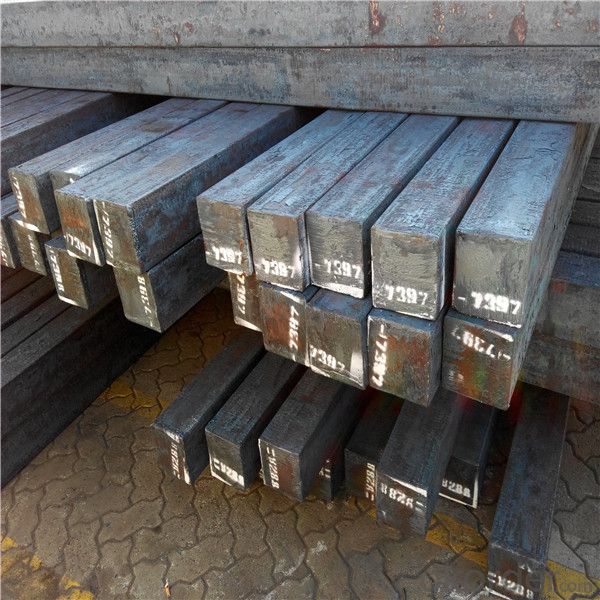

Steel billet in low price as steel material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 21643 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets used in the manufacturing of railway wagons?

- Steel billets are used in the manufacturing of railway wagons as they serve as the raw material for various components such as frames, side panels, and undercarriages. These billets are first heated and then shaped into the desired form through processes like rolling or forging. The resulting components are strong, durable, and able to withstand the rigorous demands of railway transportation, ensuring the safety and reliability of the wagons.

- Q: How do steel billets contribute to the infrastructure development?

- Steel billets play a crucial role in the infrastructure development due to their versatility and strength. These solid blocks of steel are used as a raw material in the construction of buildings, bridges, and other infrastructure projects. One of the primary ways steel billets contribute to infrastructure development is through the production of reinforced concrete. Steel rebars, which are made from steel billets, are embedded within the concrete to provide additional strength and durability. This reinforcement helps to withstand the forces exerted on the structure, ensuring its long-term stability. Moreover, steel billets are also used in the manufacturing of structural steel sections such as beams, columns, and trusses. These components are essential for constructing various types of infrastructure, including high-rise buildings and bridges. The use of steel in these applications provides excellent load-bearing capacity, allowing for the construction of large and complex structures. Steel billets are also utilized in the production of pipes, which are vital for infrastructure systems like water supply, sewage, and gas pipelines. The strength and corrosion resistance of steel make it an ideal material for these applications, ensuring the integrity and longevity of the infrastructure network. Another significant contribution of steel billets to infrastructure development is in the manufacturing of heavy machinery and equipment used in construction projects. From cranes to excavators, steel billets are used to construct the frames and other structural components of these machines, ensuring their strength and reliability. In summary, steel billets contribute to infrastructure development by providing the necessary strength and durability for various construction applications. Whether it is reinforcing concrete, manufacturing structural components, or constructing heavy machinery, steel billets play a vital role in creating resilient and long-lasting infrastructure.

- Q: Are steel billets used in the renewable energy sector?

- Certainly, the renewable energy sector makes use of steel billets. Steel, being a versatile material, finds its application in the construction of various components of renewable energy infrastructure. To illustrate, wind turbine towers, which are vital for generating wind energy, often employ steel billets in their production. This is because steel billets possess the necessary strength and durability to bear the immense weight and endure the harsh environmental conditions experienced by wind turbines. Furthermore, steel billets are also utilized in the development of solar power systems, including structures such as mounting structures and support frames for solar panels. These structures require a robust and dependable material like steel to ensure the stability and long-lasting nature of solar panels. Hence, it is evident that steel billets play an indispensable role in supporting and enabling the expansion of the renewable energy sector.

- Q: What are the challenges in welding steel billets?

- Some challenges in welding steel billets include ensuring proper joint preparation and alignment, managing heat input and distortion, selecting suitable filler materials, and controlling the formation of defects such as porosity, cracking, or incomplete fusion. Additionally, the high carbon content in certain steel billets can make them prone to hardening and cracking during the welding process, requiring specific preheating and post-weld heat treatment procedures.

- Q: What are the specifications for tool steel billets used in the manufacturing of cutting tools?

- The specifications for tool steel billets used in the manufacturing of cutting tools can vary depending on the specific application and requirements. However, there are some general specifications that are commonly followed. 1. Composition: Tool steel billets are typically made from high-carbon alloy steels that contain elements such as chromium, molybdenum, vanadium, tungsten, and cobalt. These alloying elements enhance the hardness, wear resistance, toughness, and heat resistance of the tool steel. 2. Hardness: Tool steel billets are required to have a high hardness to withstand the demanding cutting conditions. The hardness is typically measured on the Rockwell C (HRC) scale, and it can range from 58 HRC to 65 HRC or even higher for certain applications. 3. Wear Resistance: Cutting tools are subjected to abrasive wear during operation. Therefore, tool steel billets are formulated to have excellent wear resistance properties to ensure a longer tool life. This is achieved by incorporating alloying elements that form carbides, such as chromium and vanadium, which increase the hardness and wear resistance of the tool steel. 4. Toughness: While hardness and wear resistance are important, tool steel billets must also possess sufficient toughness to withstand the high impact forces generated during cutting. High toughness ensures that the cutting tools do not fracture or chip easily, even under severe cutting conditions. 5. Heat Resistance: Cutting tools are often exposed to high temperatures during operation, especially in high-speed cutting applications. Tool steel billets must have good heat resistance to prevent softening or deformation at elevated temperatures. This is achieved by adding alloying elements like molybdenum and tungsten, which contribute to the heat resistance properties of the tool steel. 6. Machinability: Tool steel billets should have good machinability to enable the production of complex cutting tool geometries with high precision. Proper selection of alloying elements and heat treatment processes can enhance the machinability of tool steel billets. It is important to note that the specific specifications for tool steel billets may vary depending on the specific cutting tool application, the material being cut, and the machining conditions. Therefore, it is crucial to consult with the tool steel manufacturer or supplier to determine the exact specifications required for a particular cutting tool application.

- Q: What are the different surface treatments for improved formability in steel billets?

- To enhance the formability of steel billets, various surface treatments can be employed. These treatments aim to increase the steel's ability to be shaped and formed without experiencing cracks or fractures. One effective method for enhancing formability is the utilization of lubricants or coatings. These substances aid in reducing friction between the steel and the forming tools, facilitating the shaping of the billets without causing any damage. Lubricants can be administered in the form of oils, greases, or solid films, and they can be utilized in both hot and cold forming procedures. Another technique for improving formability is shot peening, which entails bombarding the steel's surface with small steel or ceramic particles that possess high velocity. This process creates a compressive stress layer on the surface, effectively preventing crack initiation and propagation during the forming process. Additionally, shot peening can enhance the steel's fatigue resistance. In certain instances, heat treatment can be employed to enhance formability. This involves heating the steel to a specific temperature and rapidly cooling it. This process, known as quenching and tempering, can modify the steel's microstructure, increasing its ductility and making it easier to shape. Heat treatment also aids in relieving residual stresses in the steel, thereby improving formability. Lastly, surface coatings can be applied to steel billets to enhance formability. These coatings act as a protective barrier between the steel and the forming tools, reducing friction and preventing wear. Various methods, such as electroplating, thermal spraying, or chemical vapor deposition, can be utilized to apply these coatings. In conclusion, there exist several surface treatments that can be employed to enhance formability in steel billets. These treatments encompass the application of lubricants or coatings, shot peening, heat treatment, and surface coatings. Each treatment offers unique advantages and can be utilized based on the specific requirements of the forming process.

- Q: What is the role of steel billets in the construction of underground tunnels?

- Steel billets play a crucial role in the construction of underground tunnels as they are used to create the reinforced steel framework. These billets are shaped into various structural components, such as bars and beams, which provide strength and stability to the tunnel structure. The reinforced steel framework helps to distribute the load evenly, withstand the pressure from the surrounding soil or rock, and prevent any potential collapse or deformation of the tunnel. Therefore, steel billets contribute significantly to the overall durability and safety of underground tunnels.

- Q: How are steel billets used in the production of aerospace components?

- Steel billets are used in the production of aerospace components as they serve as the starting material for the manufacturing process. Steel billets are essentially semi-finished steel forms that are hot-rolled or forged into specific shapes and sizes. In the aerospace industry, steel billets are typically used to produce critical components such as landing gear, engine components, structural parts, and fasteners. These billets are chosen for their superior strength, durability, and resistance to high temperatures and corrosive environments, which are crucial properties required for aerospace applications. The production of aerospace components using steel billets involves several steps. First, the billets are heated to a high temperature to make them malleable and easy to work with. They are then subjected to various forming processes such as forging, extrusion, or rolling, which shape them into the desired form. These processes allow for precise shaping and dimensional accuracy, ensuring that the components meet the required specifications and tolerances. After the initial shaping, the aerospace components are subjected to further processes such as heat treatment, machining, and surface finishing to enhance their mechanical properties and improve their surface quality. Heat treatment processes such as quenching and tempering are used to strengthen the steel and improve its hardness, toughness, and resistance to wear and fatigue. Machining processes are then employed to achieve the final shape, size, and surface finish of the components. Once the components are manufactured, they undergo rigorous quality control procedures to ensure they meet the stringent standards and regulations of the aerospace industry. This includes thorough inspections, non-destructive testing, and material analysis to verify their integrity, performance, and safety. In summary, steel billets are essential in the production of aerospace components as they provide a reliable and strong starting material. The versatility and excellent mechanical properties of steel make it a preferred choice in the aerospace industry, where reliability and safety are of utmost importance.

- Q: How are steel billets used in the manufacturing of railway components?

- Steel billets play a vital role as a primary raw material in the production of railway components. The billets serve as the initial stage in the manufacturing process, being transformed into a variety of parts including rails, wheels, axles, and structural elements. To commence the transformation, the steel billets undergo heating in a furnace to achieve a specific temperature, making them more malleable and easier to shape. Once heated, the billets are then subjected to a series of rolling mills, gradually taking on the desired form. For instance, in the production of railway tracks, the heated billets are rolled and shaped into long continuous bars known as rails. These rails are subsequently cut to the required length and undergo further processes such as straightening, grinding, and drilling to meet the necessary specifications. Similarly, steel billets are also employed in the manufacturing of railway wheels and axles. The heated billets are rolled and shaped into round bars, which are then subjected to additional processing to form the wheel and axle components. These components undergo further treatments such as heat treatment, machining, and testing to ensure their strength, durability, and ability to withstand the demanding loads and stresses associated with railway operations. Furthermore, steel billets find utility in the production of other railway components such as couplers, buffers, and suspension systems. These billets are shaped and processed according to the specific requirements of each component, ensuring proper functioning and compatibility with the overall railway system. In conclusion, steel billets are an indispensable ingredient in the manufacturing of railway components. Through heating and rolling processes, they are transformed into rails, wheels, axles, and other structural elements. These components then undergo further processing and testing to guarantee their quality, reliability, and adherence to the rigorous standards of the railway industry.

- Q: How are steel billets used in the production of construction machinery attachments?

- The production of construction machinery attachments relies heavily on steel billets, which act as essential raw materials. These billets undergo a series of processes to shape and transform them into different components required for the attachments. To start, the steel billets are subjected to high temperatures to increase their malleability and facilitate easier manipulation. Subsequently, they are passed through specialized machines like rolling mills and forging presses, effectively molding them into the desired forms. This transformation allows the billets to take on various shapes such as bars, plates, and rods, which are vital for construction machinery attachments. Once shaped, the billets undergo further procedures like cutting, drilling, and shaping to create specific parts of the attachments. For instance, they can be cut and shaped to form the teeth of excavator buckets or the blades of bulldozer attachments. These parts must possess durability and strength to withstand the demanding conditions found on construction sites, and steel billets provide the necessary qualities. Furthermore, the utilization of steel billets guarantees that construction machinery attachments can endure heavy loads, impacts, and extreme temperatures. Steel is renowned for its high strength-to-weight ratio, making it an ideal material for these attachments. It can withstand the harsh conditions of construction sites and contribute to the longevity and performance of the attachments. In conclusion, steel billets play a critical role in the production of construction machinery attachments. They are transformed into various components, ensuring durability, strength, and longevity. By utilizing steel billets, construction machinery attachments can effectively fulfill their intended functions and withstand the demanding conditions encountered on construction sites.

Send your message to us

Steel billet in low price as steel material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 21643 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords