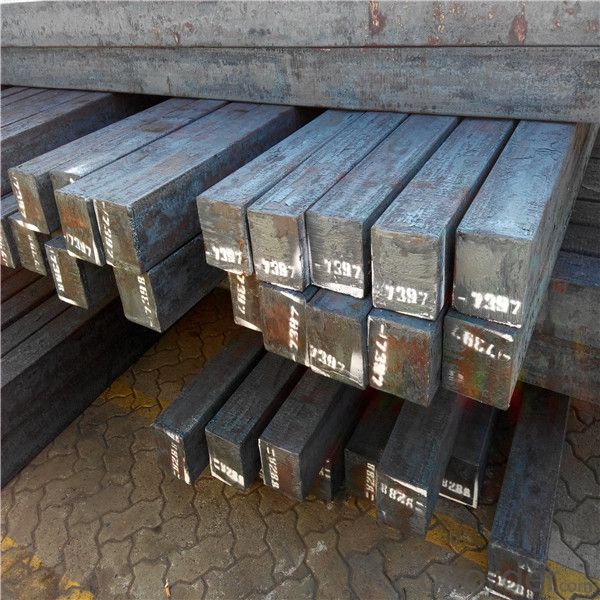

Mild steel billet price low but high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16532 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular

and abnormity of several kinds of, mainly related to the shape of rolled products.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets used in the manufacturing of industrial machinery?

- Steel billets are used in the manufacturing of industrial machinery as raw materials that are shaped and processed into various components, such as gears, shafts, and frames. These billets are heated, forged, and machined to create the desired shapes and sizes, providing the necessary strength and durability for the machinery to function effectively in various applications.

- Q: What are the different methods of steel billet surface honing?

- There are several different methods of steel billet surface honing, each serving a specific purpose and achieving different results. Some of the common methods include: 1. Manual Honing: This traditional method involves using hand-held honing tools, such as stones or abrasive pads, to manually remove any imperfections or rough surfaces from the steel billet. Skilled operators carefully rub the honing tool along the surface of the billet until the desired smoothness is achieved. 2. Mechanical Honing: In this method, mechanical honing machines are used to automate the honing process. These machines are equipped with rotating abrasive stones or pads that move along the surface of the billet, removing any irregularities. Mechanical honing allows for a more consistent and precise honing process, with the ability to control factors such as pressure, speed, and contact area. 3. Diamond Honing: Diamond honing is a specialized method that utilizes diamond-coated tools to achieve a high level of precision and smoothness. The diamond particles on the honing tool provide superior cutting capabilities, allowing for the removal of even the smallest imperfections. This method is often used for honing high-quality steel billets that require a flawless surface finish. 4. Hydrohoning: Hydrohoning, also known as abrasive flow machining, involves using a viscous abrasive medium that is forced through the billet's internal passages to remove any surface irregularities. This method is especially effective for honing complex shapes or internal surfaces that are difficult to reach through other methods. The abrasive medium can be adjusted to achieve different levels of surface finish. 5. Electrochemical Honing: Electrochemical honing is a technique that combines the principles of electrochemical machining and honing. It involves using a special electrolyte solution and a honing tool with an electrode to remove material from the billet's surface. This method is effective for honing hard materials and achieving a smooth, mirror-like finish. These are just some of the different methods of steel billet surface honing. The choice of method depends on factors such as the desired surface finish, the complexity of the billet's shape, the material being honed, and the level of precision required.

- Q: How are steel billets used in the production of wind turbine towers?

- Steel billets are used in the production of wind turbine towers as they serve as the primary raw material. These billets are heated and then shaped into the required cylindrical or conical form, which is essential for the structural integrity of the tower. The billets are then welded together to form the tower sections, which are further assembled and erected to support the wind turbine components.

- Q: How do steel billets contribute to the manufacturing of rail and transportation systems?

- Steel billets are an essential raw material in the manufacturing of rail and transportation systems. These billets serve as the starting point for the production of various components, such as rails, wheels, axles, and structural supports. Through a series of processes like rolling, forging, and machining, steel billets are transformed into these vital parts, which provide strength, durability, and stability to rail tracks, locomotives, and other transportation vehicles. In summary, steel billets are crucial in ensuring the reliability and safety of rail and transportation systems.

- Q: What is the role of steel billets in the production of automotive components?

- The production of automotive components heavily relies on steel billets, which serve as essential raw materials. These semi-finished metal products play a vital role in manufacturing various parts utilized in the automotive industry. To begin with, engine components such as crankshafts, camshafts, and connecting rods are manufactured using steel billets. These components are crucial for the smooth functioning of the engine. Steel's strong and durable properties make it an ideal material for these parts, ensuring their ability to withstand the high temperatures and pressures within the engine. In addition, chassis and suspension components are produced using steel billets. These components, including control arms, steering knuckles, and axle shafts, are responsible for the vehicle's stability, maneuverability, and overall performance. Steel's high strength-to-weight ratio and excellent fatigue resistance make it suitable for these safety-critical components. Moreover, transmission and drivetrain components also rely on steel billets. Gears, shafts, and clutch plates, which are essential for transmitting power from the engine to the wheels, are manufactured using steel billets. Steel's toughness, wear resistance, and ability to handle high torque loads make it an ideal material for these parts, ensuring their durability and reliability. Furthermore, body and interior components are manufactured using steel billets. These components can include door hinges, brackets, seat frames, and various structural parts. Steel's versatility, formability, and corrosion resistance make it an excellent choice for these components, providing strength and protection to the vehicle's occupants. In summary, steel billets serve as the foundation for the production of a wide range of automotive components. Their strength, durability, and reliability are essential for critical parts in engines, chassis, transmission systems, and body structures. Without steel billets, the automotive industry would face challenges in producing high-quality and safe vehicles.

- Q: What are the different types of steel used for manufacturing billets?

- There are several different types of steel that are commonly used for manufacturing billets, each with its own unique properties and applications. Some of the most common types of steel used for this purpose include: 1. Mild Steel: This is one of the most widely used types of steel for manufacturing billets. It has a low carbon content and is known for its strength and ductility. Mild steel is often used for general purpose applications where high strength is not required. 2. Carbon Steel: This type of steel contains higher levels of carbon compared to mild steel. It offers improved hardness and strength, making it suitable for applications that require greater resistance to wear and tear, such as tools and machinery components. 3. Alloy Steel: Alloy steel is made by adding various alloying elements, such as manganese, nickel, chromium, or molybdenum, to the base iron. This results in a steel with enhanced properties such as increased strength, durability, and corrosion resistance. Alloy steel billets are commonly used in the automotive, aerospace, and construction industries. 4. Stainless Steel: Stainless steel is a steel alloy that contains a minimum of 10.5% chromium, which provides excellent resistance to corrosion and staining. This makes it ideal for applications that require high levels of hygiene, such as food processing equipment and medical devices. 5. Tool Steel: Tool steel is a type of high-carbon steel that is specifically designed to be used in the production of tools, dies, and molds. It is known for its hardness, wear resistance, and ability to retain its shape at high temperatures. 6. High-Speed Steel: High-speed steel is a type of tool steel that is specifically designed to withstand high temperatures without losing its hardness. It is commonly used for cutting tools, such as drills and milling cutters. These are just a few examples of the different types of steel used for manufacturing billets. The choice of steel will depend on the specific requirements of the application, such as strength, durability, corrosion resistance, and temperature resistance.

- Q: What are the different surface finishes available for tool steel billets?

- Tool steel billets offer a range of surface finishes to cater to different requirements and applications. Some commonly used surface finishes are as follows: 1. Hot Rolled: This is the most basic surface finish achieved by hot rolling the steel billets, resulting in a rough and scaled surface. It is suitable for applications where a smooth finish is not crucial. 2. Cold Rolled: For a smoother and refined surface finish, the steel billets undergo cold rolling. Cold rolled surfaces are preferred when a higher degree of precision and accuracy is required. 3. Turned: By using a lathe to remove material, the steel billet can achieve a smooth and polished surface finish. Turned surfaces are commonly employed in applications where aesthetic appearance and precision components are essential. 4. Ground: Grinding is employed to achieve a flat and smooth surface finish on tool steel billets. It is commonly utilized when a high level of precision and dimensional accuracy is necessary, particularly in tooling applications. 5. Polished: This is the most refined surface finish achieved by using abrasives and polishing compounds, resulting in a mirror-like surface. Polished surfaces are often chosen for decorative or high-end applications where a visually appealing finish is desired. 6. Coated: Additionally, tool steel billets can be coated with various materials to enhance their surface properties. Coatings such as nitride, carbide, or diamond-like carbon (DLC) can improve hardness, wear resistance, and friction properties. The choice of surface finish for tool steel billets depends on specific requirements, including desired accuracy, appearance, and performance characteristics.

- Q: How are steel billets used in the production of automotive steering systems?

- Automotive steering systems rely heavily on steel billets, a crucial element in their manufacturing. These billets, typically crafted from high-quality steel, serve as the raw material for producing various steering system components like shafts, gears, and housings. The production process begins by heating and softening the steel billets to increase their malleability. This allows them to be easily molded and shaped into the desired steering system components through methods such as forging, rolling, or casting. The chosen technique depends on the complexity and function of the component being manufactured. Once the desired shape is achieved, the steel billets undergo further processing to enhance their strength and durability. This involves employing heat treatment techniques like quenching and tempering, which provide the steel with specific mechanical properties like improved hardness and toughness. These treatments ensure that the steering system components can handle the considerable loads and vibrations experienced during operation. After proper shaping and treatment, the billets undergo precision machining processes to attain the required dimensional accuracy and surface finish. This includes cutting, drilling, and grinding the billets to create the necessary profiles and features that enable optimal functioning within the steering system. Lastly, the finished steering system components are assembled together with other parts to create the complete automotive steering system. These components, manufactured from steel billets, play a critical role in transmitting driver input to the wheels, enabling precise control and maneuverability of the vehicle. In summary, steel billets are indispensable in the production of automotive steering systems as they provide the necessary strength, durability, and precision required for safe and efficient vehicle steering.

- Q: Are steel billets prone to cracking during production?

- Yes, steel billets are prone to cracking during production. Due to the high temperatures and rapid cooling involved in the production process, internal stresses can develop in the billets, leading to cracks. Proper handling, heat treatment, and quality control measures can help minimize the risk of cracking.

- Q: What are the different methods of surface inspection for steel billets?

- There are several methods of surface inspection for steel billets, which are used to identify any defects or irregularities on the surface. These methods include visual inspection, magnetic particle inspection, liquid penetrant inspection, ultrasonic inspection, and eddy current inspection. Visual inspection is the simplest and most commonly used method, where inspectors visually examine the surface of the billets for any visible defects such as cracks, pits, or surface irregularities. This method relies on the expertise and experience of the inspector. Magnetic particle inspection involves the use of magnetic fields and magnetic particles to detect surface and near-surface defects. A magnetic field is applied to the steel billet, and magnetic particles are applied to the surface. If there is a defect, the magnetic particles will be attracted to it, making the defect visible under proper lighting. Liquid penetrant inspection is another method used to detect surface defects. In this method, a liquid penetrant is applied to the surface of the billet. The penetrant seeps into any surface defects, and after a certain amount of time, excess penetrant is removed. A developer is then applied, which draws the penetrant out of the defects, making them visible. Ultrasonic inspection involves the use of high-frequency sound waves to detect internal and surface defects. A transducer is used to emit sound waves into the billet, and the reflected waves are analyzed to identify any defects. This method can detect defects such as cracks, voids, and inclusions. Eddy current inspection is a non-destructive testing method that uses electromagnetic induction to detect surface defects. A probe is moved over the surface of the billet, and an alternating current is passed through it. Any surface irregularities or defects will disrupt the flow of current, which can be detected and analyzed. Each of these methods has its own advantages and limitations, and the choice of method depends on the specific requirements and constraints of the inspection process. By utilizing these different methods, manufacturers can ensure the quality and reliability of steel billets before they are further processed or used in various applications.

Send your message to us

Mild steel billet price low but high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16532 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords