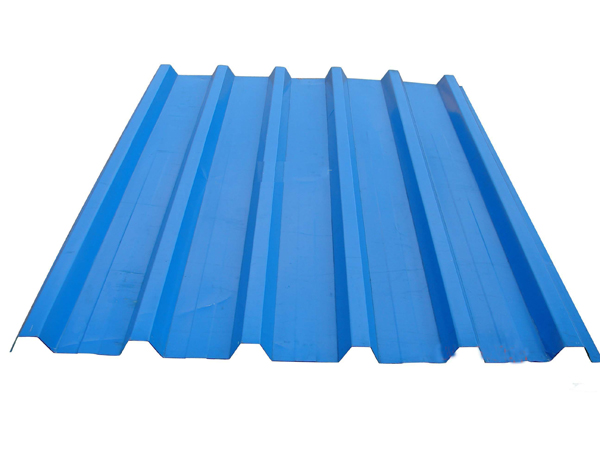

Corrugated Color Steel Sheet with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 180000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated steel sheet

Corrugated steel sheet is a building material composed of sheets of hot-dip galvanised mild steel, cold-rolled to produce a linear corrugated pattern in them. The corrugations increase the bending strength of the sheet in the direction perpendicular to the corrugations, but not parallel to them. Normally each sheet is manufactured longer in its strong direction.

Characteristic

CGI is lightweight and easily transported. It was and still is widely used especially in rural and military buildings such as sheds and water tanks. Its unique properties were used in the development of countries like Australia from the 1840s, and it is still helping developing countries today.

Packaging & Delivery

Packaging Details:by plastic film

Delivery Detail:15days

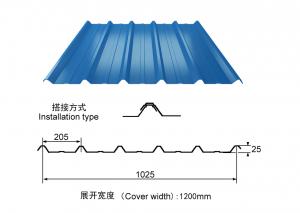

Specifications

thickness:0.3mm-0.6mm

width:840mm

length:less 12m

color:red blue white grey

- Q: What are the safety precautions when handling steel sheets?

- When handling steel sheets, there are several safety precautions that should be followed to ensure the well-being of individuals and prevent accidents. These precautions include the following: 1. Personal Protective Equipment (PPE): It is essential to wear the appropriate PPE when handling steel sheets. This typically includes safety goggles or glasses, gloves, and steel-toed boots. PPE helps protect against potential injuries such as cuts, burns, and eye damage. 2. Proper Lifting Techniques: Steel sheets can be heavy and awkward to handle, so it is crucial to use proper lifting techniques to avoid strain or injury. Lift with your legs, not your back, and use team lifting when necessary. Avoid any sudden or jerky movements while handling the sheets. 3. Secure Storage and Transport: When storing or transporting steel sheets, ensure that they are properly secured to prevent them from shifting or falling. Use appropriate equipment such as straps or chains to secure the sheets, and make sure they are evenly distributed to maintain balance. 4. Clear Work Area: Before handling steel sheets, ensure that the work area is clear of any obstacles or debris. This will help prevent tripping or slipping hazards and provide a clear path for moving the sheets. 5. Adequate Lighting: Proper lighting is essential to ensure good visibility when handling steel sheets. Insufficient lighting can increase the risk of accidents and injuries, so make sure the work area is well-lit to avoid any potential mishaps. 6. Training and Education: It is important for individuals handling steel sheets to receive proper training and education on safe handling procedures. This includes understanding the weight and dimensions of the sheets, as well as the correct techniques for lifting and moving them. 7. Awareness of Sharp Edges: Steel sheets often have sharp edges, which can cause cuts or lacerations. Always handle the sheets with caution and be aware of any sharp edges. If necessary, use protective guards or edge protectors to minimize the risk of injury. 8. Regular Maintenance and Inspection: Regularly inspect the steel sheets for any signs of damage, such as sharp edges, rust, or structural weaknesses. Replace or repair any damaged sheets to ensure safe handling. By following these safety precautions, individuals can minimize the risk of accidents and injuries when handling steel sheets. It is important to prioritize safety and take the necessary steps to protect oneself and others in the work environment.

- Q: Are steel sheets suitable for automotive exhaust systems?

- Indeed, automotive exhaust systems find steel sheets to be a suitable choice. Steel, being highly durable, strong, and resistant to both high temperatures and corrosion, is extensively used in the manufacturing of exhaust systems. Given that automotive exhaust systems endure intense heat and corrosive gases, steel sheets prove to be exceptionally capable of withstanding such conditions. Moreover, steel sheets possess the advantageous ability to be easily molded and welded, thus making them perfectly suited for the intricate shapes and configurations demanded by exhaust system components. Ultimately, steel sheets offer the essential properties and characteristics required for automotive exhaust systems, rendering them an apt selection for this particular application.

- Q: Are steel sheets suitable for high-pressure applications?

- Yes, steel sheets are suitable for high-pressure applications due to their excellent strength and durability. Steel has a high tensile strength and can withstand high-pressure conditions without deformation or failure, making it an ideal choice for various industries such as oil and gas, automotive, and construction.

- Q: What are the common uses for steel sheets?

- Steel sheets are commonly used in construction projects as roofing, siding, and structural support. They are also used in manufacturing industries for making automotive parts, appliances, and machinery. Additionally, steel sheets are used in the fabrication of containers, storage tanks, and transportation infrastructure.

- Q: What is the difference between a smooth and diamond plate steel sheet?

- A smooth steel sheet has a flat and even surface, whereas a diamond plate steel sheet has a raised diamond pattern on its surface. This pattern provides additional traction and grip, making it suitable for applications that require slip resistance, such as stairs, ramps, or industrial flooring.

- Q: What are the different types of steel sheet finishes for decorative purposes?

- For decorative purposes, one can find several varieties of steel sheet finishes that are commonly utilized. These finishes are applied to the steel sheet's surface with the intention of enhancing its appearance and achieving a desired aesthetic effect. Some of the most favored finishes for decorative purposes are as follows: 1. Brushed Finish: Achieved by brushing the steel sheet's surface with a fine abrasive material, usually in a straight line pattern, this finish imparts a smooth and satin-like appearance. It is widely used in architectural and interior design applications. 2. Mirror Finish: Also known as a polished finish, this type creates a highly reflective surface that resembles a mirror. The steel sheet is mechanically polished to achieve this finish, and it is commonly seen in decorative applications such as furniture, lighting fixtures, and signage. 3. Patterned Finish: This finish involves embossing or etching a pattern onto the steel sheet's surface. It can be achieved through various techniques like stamping, laser engraving, or chemical etching. Patterned finishes provide a decorative and textured appearance and are often used in applications like elevator panels, wall cladding, and decorative screens. 4. Colored Finish: To add vibrancy and enhance visual appeal, steel sheets can be coated with a colored finish. Processes such as powder coating are employed, where a dry powder is applied to the steel sheet and then cured to create a durable, colored finish. Colored finishes are commonly used in architectural applications like building facades and signage. 5. Antique Finish: This particular finish is designed to give the steel sheet an aged or weathered look, resembling antique metal. Various techniques such as chemical treatments, patinas, or distressing can be employed to achieve this appearance. Antique finishes are often utilized in decorative applications to create a rustic or vintage aesthetic. These are just a few examples of the diverse range of steel sheet finishes available for decorative purposes. Each finish provides a distinct appearance and can be customized to suit specific design preferences. The choice of finish relies on factors such as the desired look, application, and required level of durability for the project.

- Q: What is the difference between a brushed and polished steel sheet?

- A brushed steel sheet and a polished steel sheet differ in terms of their surface finishes. A brushed steel sheet is characterized by a pattern of parallel lines or scratches on its surface, created using abrasive materials or tools. The purpose of brushing is to give the steel sheet a textured appearance, which helps to hide fingerprints, scratches, and wear over time. It also provides a more industrial, matte finish. On the other hand, a polished steel sheet has a smooth and glossy surface. Polishing involves using polishing compounds or abrasive materials to remove imperfections, scratches, and oxidation from the steel surface. This process creates a reflective and mirror-like finish, enhancing the aesthetic appeal of the steel sheet. Polished steel sheets are commonly used in applications where appearance and visual appeal are important, such as architectural design, interior decoration, and high-end products. In summary, the main difference between a brushed and polished steel sheet lies in their surface finishes. Brushed steel sheets have a textured, matte appearance, while polished steel sheets have a smooth and glossy, mirror-like finish. The choice between the two depends on the desired aesthetic, functional requirements, and the intended application of the steel sheet.

- Q: What are the functions and classifications of galvanized sheet?

- Transportation industry: car, car, car shell ceiling board, tractor, tram, container, highway fence, ship bulkhead etc.Other instruments shell, trash, billboards, watches, photographic equipment, measuring devices and other color coated steel plate with hot galvanized plate, hot galvanized plate, galvanized plate as the substrate, the surface of galvanized plate type pre processing include: hot galvanized plate, galvanized plate, tinplate, galvanized plate pressing and molding, with connecting hooks, without any accessories can be securely firmly connected mesh columns.Galvanized sheet according to its use can be divided into: activated alumina, galvanized plate, desiccant, galvanized plate and catalyst galvanized sheet. The inner cavity of the working room is made of high quality galvanized or stainless steel plate to make it rustproof and clean;

- Q: Are steel sheets resistant to impact?

- Yes, steel sheets are generally resistant to impact due to their high strength and durability.

- Q: Is the steel plate 1.5 meters wide and 2 meters wide at the same price? .

- The steel plate price is generally not the width, they only according to the different material steel plate, gives you to quote the unit price.

Send your message to us

Corrugated Color Steel Sheet with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 180000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords