Stainless Steel plate and sheet 430 with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

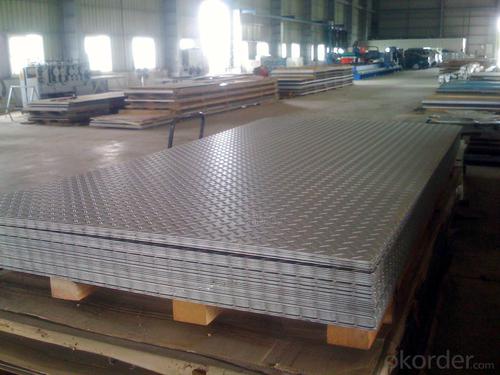

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

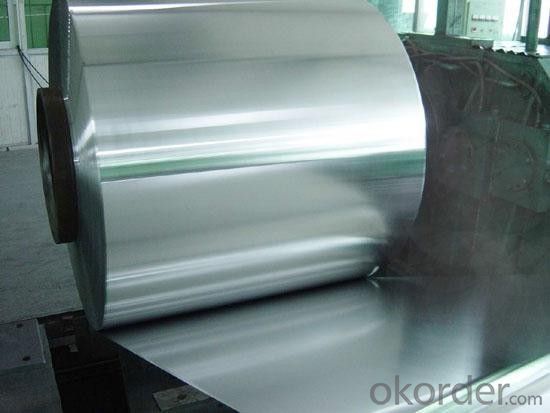

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for food processing applications?

- Stainless steel sheets excel in food processing applications. Renowned for their exceptional corrosion resistance, stainless steel proves ideal for environments exposed to moisture, chemicals, and food substances. Moreover, its non-porous nature prevents bacterial absorption and contamination, ensuring a hygienic and easily cleaned surface. Additionally, stainless steel sheets' heat resistance allows them to endure high temperatures, rendering them perfect for cooking and processing. Furthermore, their durability and longevity guarantee they can withstand the rigorous demands of food processing operations. Ultimately, the food industry favors stainless steel sheets due to their cleanliness, durability, and corrosion resistance.

- Q: What's the difference between cold rolled plate and stainless steel?

- Cold rolled steel plates will soon rust (in the wind and rain). Rust must be painted outsideAs the price of chromium and nickel is very high, the price of stainless steel plate is several times that of ordinary cold-rolled steel sheet

- Q: Can stainless steel sheets be used for swimming pool installations?

- Certainly! Stainless steel sheets are a great option for swimming pool installations. With their exceptional durability and resistance to corrosion, stainless steel is well-suited for use in pools. It can withstand rust, stains, and the various chemicals usually present in pool water, making it a dependable choice for long-term usage. In fact, stainless steel sheets are frequently employed for constructing pool walls, floors, and other crucial components due to their ability to endure the challenging conditions typical of pool environments. Moreover, stainless steel possesses a sleek and contemporary look that contributes to the pool's overall aesthetic appeal.

- Q: Are stainless steel sheets suitable for chemical storage tanks?

- Yes, stainless steel sheets are suitable for chemical storage tanks. Stainless steel is known for its corrosion resistance and durability, making it an excellent choice for storing various chemicals. It is resistant to many corrosive substances, including acids, alkalis, and solvents, which are commonly stored in chemical storage tanks. Stainless steel sheets also have a high strength-to-weight ratio, allowing for the construction of tanks that can withstand the pressure and weight of the chemicals. Additionally, stainless steel is easy to clean and maintain, making it a hygienic option for storing chemicals. Overall, stainless steel sheets are a reliable and suitable material for chemical storage tanks.

- Q: Can stainless steel sheets be used for marine propellers?

- Yes, stainless steel sheets can be used for marine propellers. Stainless steel is a popular choice for marine propellers due to its excellent corrosion resistance properties. The high levels of chromium in stainless steel make it resistant to rust and other forms of corrosion, even in saltwater environments. Additionally, stainless steel offers good strength and durability, making it suitable for withstanding the harsh conditions of marine environments. Stainless steel propellers are often preferred for boats and ships as they require less maintenance and have a longer lifespan compared to other materials. However, it is important to choose the appropriate grade of stainless steel for marine propellers to ensure optimal performance and longevity.

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- To prevent pitting or crevice corrosion on stainless steel sheets, certain measures can be taken. First, ensuring proper cleaning and maintenance is crucial. Regularly cleaning the stainless steel sheets with mild detergent and water, followed by thorough rinsing and drying, helps remove any contaminants that can lead to corrosion. Additionally, avoiding exposure to corrosive substances like chloride-based cleaners or harsh chemicals is important. Applying a protective coating or passivating the stainless steel surface can also provide an extra barrier against corrosion. Passivation involves treating the stainless steel with a mild oxidizing agent to promote the formation of a passive oxide layer, which enhances the metal's resistance to corrosion. Proper design and installation practices are equally vital. Avoiding the use of dissimilar metals in contact with stainless steel sheets and ensuring proper sealing and gasketing in joints or crevices can prevent crevice corrosion. Adequate ventilation and avoiding stagnant conditions can also help minimize corrosion risks. Regular inspection and maintenance are necessary to identify and address any signs of corrosion promptly. This includes checking for signs of pitting or crevices, addressing any damage or scratches, and promptly repairing or replacing any corroded areas.

- Q: Can stainless steel sheets be used for electromagnetic compatibility?

- Yes, stainless steel sheets can be used for electromagnetic compatibility. Stainless steel is a highly conductive material that can effectively shield against electromagnetic interference (EMI) and radio frequency interference (RFI). It can be used to create enclosures or shielding to protect sensitive electronic devices from external electromagnetic fields.

- Q: Do stainless steel sheets require any special handling during installation?

- Yes, stainless steel sheets require special handling during installation to ensure their proper installation and to prevent damage. Some important considerations include using proper lifting equipment, ensuring a clean and dry surface, avoiding contact with other metals to prevent galvanic corrosion, and following the manufacturer's guidelines for installation and maintenance.

- Q: Can stainless steel sheets be painted?

- Yes, stainless steel sheets can be painted. However, it is important to properly prepare the surface before painting to ensure good adhesion and longevity of the paint. The stainless steel surface should be cleaned and degreased thoroughly, and any existing rust or oxidation should be removed. A primer specifically formulated for use on metal surfaces should be applied to promote adhesion, followed by a high-quality paint designed for metal. It is also recommended to apply a clear coat or sealer to protect the paint finish. Keep in mind that regular maintenance may be required to maintain the appearance of the painted stainless steel sheets, as the paint may chip or wear over time.

- Q: How do stainless steel sheets compare to other types of metal sheets?

- Stainless steel sheets have several advantages that set them apart from other types of metal sheets. Firstly, stainless steel is highly resistant to corrosion, making it an excellent choice for applications where durability and longevity are crucial. Unlike other metals, stainless steel does not easily rust or stain, which ensures its appearance and functionality remain intact even in challenging environments. Secondly, stainless steel sheets are known for their strength and robustness. They have a high tensile strength, meaning they can withstand heavy loads without bending or warping. This makes stainless steel sheets suitable for a wide range of applications, including construction, automotive, and manufacturing industries. Another significant advantage of stainless steel sheets is their hygienic properties. Stainless steel is non-porous and non-absorbent, making it easy to clean and maintain. It is also resistant to bacterial growth, making it a popular choice for medical equipment, food processing facilities, and kitchen appliances. Furthermore, stainless steel sheets offer excellent heat resistance. They can withstand high temperatures without losing their structural integrity or forming any deformities, making them suitable for applications involving extreme heat or thermal cycling. Lastly, stainless steel sheets come in a variety of finishes and textures, providing versatility in design options. Whether you prefer a polished, brushed, or matte finish, stainless steel allows for customization to match any aesthetic requirement. In summary, stainless steel sheets are superior to other types of metal sheets due to their exceptional corrosion resistance, strength, hygienic properties, heat resistance, and aesthetic versatility. These qualities make stainless steel sheets the go-to choice for various industries, ensuring durability, reliability, and longevity in numerous applications.

Send your message to us

Stainless Steel plate and sheet 430 with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords