Stainless Steel plate and sheet 420 with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

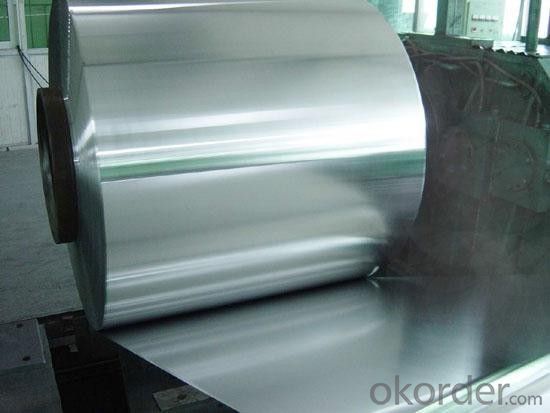

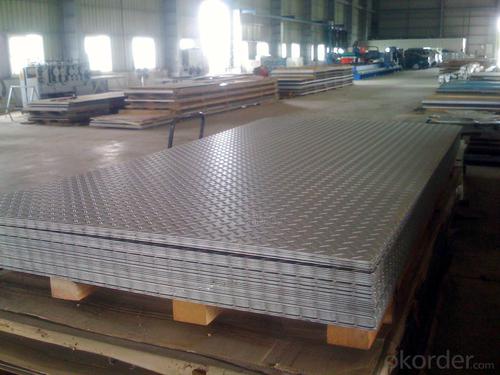

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

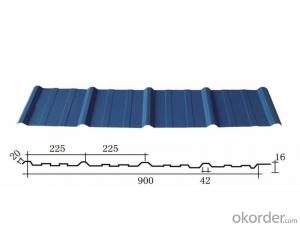

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for architectural wire mesh?

- Yes, stainless steel sheets are suitable for architectural wire mesh. Stainless steel is a durable and corrosion-resistant material, making it ideal for outdoor applications. It provides strength and stability to the wire mesh, ensuring longevity and aesthetic appeal in architectural designs.

- Q: Can stainless steel sheets be used in the aerospace industry?

- Certainly, the aerospace industry can indeed employ stainless steel sheets. With its exceptional mechanical properties, corrosion resistance, and high strength-to-weight ratio, stainless steel is an incredibly versatile material. Hence, it finds great applicability in numerous aerospace uses. For instance, it is frequently utilized in fabricating aircraft elements like engine parts, structural frames, fuel tanks, and exhaust systems. Moreover, stainless steel sheets are also employed in manufacturing aerospace fittings, fasteners, and even interior cabin components. Thanks to its outstanding durability and ability to withstand extreme environments and temperature variations, stainless steel remains a dependable choice for the aerospace industry.

- Q: Who knows the production process of stainless steel plate?

- Sanitary conditions are important for many industries, such as food processing, catering, brewing and chemical processes. In these applications, the surface must be cleaned daily and chemical cleaning agents are often used.Stainless steel is the best material in this area, in public places, the surface of the stainless steel is often scribbles, but an important characteristic is it can be washed off, this is a remarkable characteristic of stainless steel is better than aluminum. The surface of aluminum tends to leave traces that are often difficult to remove. When cleaning the stainless steel surface, it should be cleaned along the lines of stainless steel, because some of the surface finishing lines are unidirectional.Stainless steel most suitable for hospital or other health conditions of critical field, such as: food processing, food, brewing and chemical industry, this is not only because it is easy to clean every day, sometimes the use of chemical cleaning agents, but also because it is not easy to breed bacteria. Tests show that stainless steel has the same properties in this field as glass and ceramics.

- Q: How do you remove water stains from stainless steel sheets?

- To remove water stains from stainless steel sheets, you can follow these steps: 1. Start by wiping the surface of the stainless steel sheet with a soft, damp cloth to remove any loose dirt or debris. 2. Mix a solution of warm water and mild dish soap in a bucket or bowl. Dip a clean cloth into the soapy water and wring out any excess liquid. 3. Gently rub the cloth over the water stains on the stainless steel sheet. Make sure to go along the grain of the stainless steel to prevent any further damage or scratching. 4. For tougher water stains, you can use a non-abrasive cleaner specifically designed for stainless steel. Apply a small amount of the cleaner to a clean cloth and gently rub it onto the stained areas. 5. Rinse the stainless steel sheet with clean water to remove any soap residue. Use a separate clean cloth or sponge to wipe away any excess water. 6. To prevent future water stains, you can apply a stainless steel cleaner or polish to the surface. Follow the instructions on the product label for the best results. Remember to always test any cleaning solution or product on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will ensure that the cleaner or polish does not cause any damage or discoloration.

- Q: Can stainless steel sheets be used for outdoor signage?

- Indeed, outdoor signage can be made using stainless steel sheets. This material, known for its durability and resistance to corrosion, remains unscathed in challenging weather conditions while preserving its visual appeal. Its widespread use in outdoor signage can be attributed to its ability to withstand rust, fading, and harm caused by sunlight, rain, snow, and other environmental factors. Moreover, stainless steel sheets can be personalized with different finishes like brushed or polished, enhancing their aesthetic allure and making them suitable for any outdoor signage requirement.

- Q: What glue does the board and the stainless steel stick to?

- In addition to the bonding (ordinary bonding and bonding structure), epoxy resin can be used for casting, sealing, sealing, sealing, anti-corrosion, insulation, conductive, fixed, reinforcement, repair etc., are widely used in aviation, aerospace, ships, railway, machinery, chemical industry, light industry, water conservancy, weapons, electronic and electrical, construction, medical, sports goods, arts and crafts, daily life and other fields.

- Q: Are stainless steel sheets suitable for elevator floor panels?

- Indeed, elevator floor panels can be made from stainless steel sheets. Stainless steel, as a robust and long-lasting material, possesses corrosion resistance, thereby rendering it appropriate for areas with heavy foot traffic such as elevator floors. Moreover, it boasts effortless cleaning and maintenance properties, making it a perfect fit for public spaces. Additionally, stainless steel sheets can be tailored to specific design needs and aesthetic preferences in terms of size, shape, and finish. In summary, stainless steel sheets provide elevator floor panels with a harmonious blend of durability, visual allure, and maintenance convenience, making them an excellent choice.

- Q: What is the lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, the environment in which they are used, and the maintenance practices followed. In general, stainless steel sheets have a long lifespan and are known for their durability and corrosion resistance. They are designed to withstand harsh conditions and are resistant to rust, stains, and other forms of degradation. Stainless steel sheets are typically made from austenitic stainless steel, which is known for its high levels of chromium and nickel. These elements provide excellent corrosion resistance and make stainless steel sheets highly resistant to rust and staining. As a result, stainless steel sheets can last for many years, often outlasting other materials such as aluminum or regular steel. The lifespan of stainless steel sheets can be further extended through proper care and maintenance. Regular cleaning and removal of any contaminants or debris can help prevent corrosion and maintain the appearance and performance of the sheets. Additionally, applying protective coatings or finishes can provide an extra layer of protection against corrosion and wear. While it is difficult to provide an exact lifespan for stainless steel sheets due to the variability of factors involved, with proper care and maintenance, they can easily last for several decades. In some cases, stainless steel sheets have been known to last for over a century. Therefore, investing in stainless steel sheets is often seen as a long-term solution, offering durability and cost-effectiveness over an extended period.

- Q: What are the different types of punched finishes available for stainless steel sheets?

- There are several types of punched finishes available for stainless steel sheets, including round hole, square hole, slotted hole, and decorative patterns. Each type offers a unique aesthetic and functional purpose, allowing for customized designs and applications.

- Q: Can stainless steel sheets be used for water tanks or storage containers?

- Yes, stainless steel sheets can be used for water tanks or storage containers. Stainless steel is known for its durability, corrosion resistance, and hygienic properties, making it an excellent choice for storing water or other liquids. It is commonly used in various industries, including food and beverage, pharmaceuticals, and chemical storage, due to its ability to maintain the quality and purity of the stored substances.

Send your message to us

Stainless Steel plate and sheet 420 with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords