Stainless Steel 316 sheet and plate with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel 316 sheet and plate with plenty stock

Description of Stainless Steel 316 sheet and plate with plenty stock:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel 316 sheet and plate with plenty stock:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Maintance of Stainless Steel 316 sheet and plate with plenty stock:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Applications of Stainless Steel 316 sheet and plate with plenty stock:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many applications. There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates, bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipment Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion resistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steamcleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel 316 sheet and plate with plenty stock:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics of Stainless Steel 316 sheet and plate with plenty stock:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

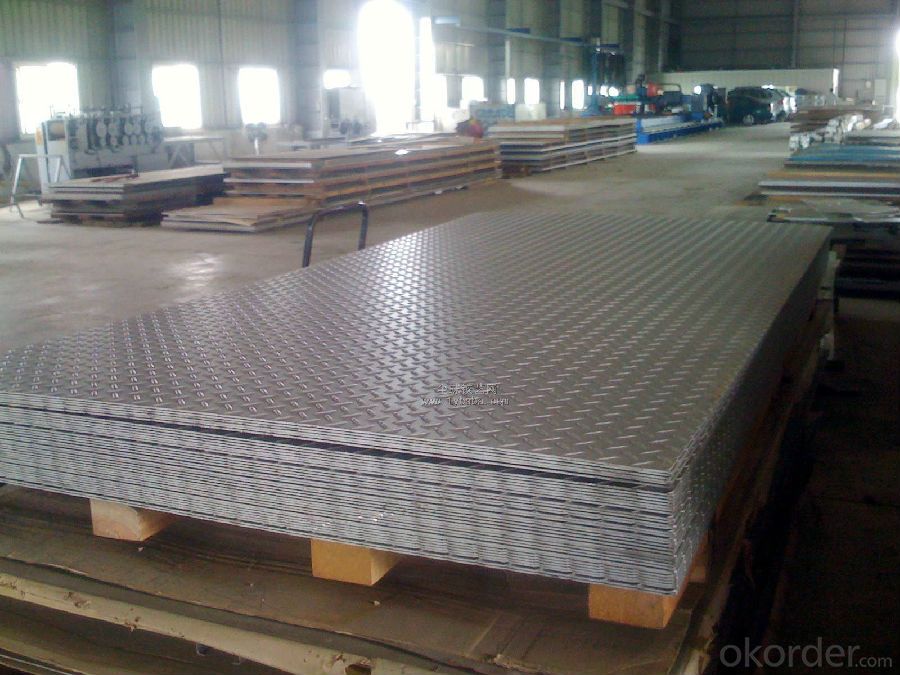

Images of Stainless Steel 316 sheet and plate with plenty stock:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

Our company adheres to the tenet of "survival by quality, build brand by reputation, win market by prices and innovate to develop", has developed international markets and the products are well sold in many countries as Singapore, Indonesia, South Korea, Dubai, Pakistan, Sri Lanka, Vietnam, Iran, Malaysia, Mexico, Chile, Brazil, Holland, Italy, Belgium, Russia, Moldova, Paraguay, Uruguay, Germany, Spain, USA etc. More than 40 countries.; commonly we have more than 500tons stainless steel materials in stock; so w can arrange the soonest delivery too; also we hope we will have chance to cooperate with your esteemed company!

- Q: Are stainless steel sheets suitable for food processing applications?

- Yes, stainless steel sheets are highly suitable for food processing applications. Stainless steel is known for its excellent corrosion resistance, making it ideal for use in environments that involve exposure to moisture, chemicals, and food substances. It is also non-porous, which means it does not absorb bacteria or other contaminants, making it hygienic and easy to clean. Stainless steel sheets are also heat resistant and can withstand high temperatures, making them suitable for cooking and processing applications. Additionally, stainless steel is durable and long-lasting, ensuring that it can withstand the demands of food processing operations. Overall, stainless steel sheets are a popular choice in the food industry due to their cleanliness, durability, and resistance to corrosion.

- Q: What are the different types of stainless steel sheet thicknesses available?

- There are various types of stainless steel sheet thicknesses available, ranging from thin sheets with thicknesses as low as 0.4mm to thicker sheets with thicknesses up to 6mm or more. The specific thicknesses available may vary depending on the manufacturer and the intended application of the stainless steel sheet.

- Q: How do you prevent scratching on stainless steel sheets during handling and installation?

- To prevent scratching on stainless steel sheets during handling and installation, there are several steps you can take: 1. Use protective covering: Apply a protective covering or film on the surface of the stainless steel sheets before handling or installing them. This covering acts as a barrier, preventing scratches and scuff marks during transportation and installation. Ensure that the covering is suitable for stainless steel and does not leave any residue upon removal. 2. Handle with care: Be mindful of how you handle the stainless steel sheets. Avoid dragging or sliding them against rough surfaces or each other, as this can cause scratches. Instead, use proper lifting techniques and handle the sheets with clean, dry hands or gloves to minimize the risk of leaving marks. 3. Use appropriate tools: When working with stainless steel sheets, make sure to use tools that are specifically designed for this purpose. Avoid using tools with rough or abrasive surfaces that could scratch the stainless steel. Opt for tools made from soft materials or with protective coatings to minimize the chances of damaging the surface. 4. Clean work areas: Before installing stainless steel sheets, ensure that the work area is clean and free from any debris or particles that could potentially scratch the surface. Wipe down the area with a clean cloth or soft brush to remove any dirt, dust, or loose materials that could cause scratches during installation. 5. Secure sheets during transportation: If you need to transport stainless steel sheets, ensure that they are properly secured to prevent any movement or shifting that could lead to scratches. Use appropriate packaging materials such as foam inserts, edge protectors, or straps to keep the sheets in place and minimize the risk of damage. By following these preventive measures, you can significantly reduce the risk of scratching stainless steel sheets during handling and installation, ensuring a pristine finish and maintaining the quality of the material.

- Q: Why do galvanized and stainless steel sheets buy more expensive than thin ones?

- Feels like you rarely buy stainless steel plates. First of all, galvanized sheet or stainless steel is made of thick hot-rolled billets by cold rolling, so the thickness is generally thinner, and the more processing times, the greater the cost. That's why the thinner is thicker than the expensive one. Once again, the plate has a negative range of thickness, not necessarily all feet thick, and when buying a flat, with suppliers to explain your negative range requirements. If the 1.2MM board gives you 1.0MM, it's a bit too exaggerated.

- Q: Can stainless steel sheets be used for staircase railings?

- Yes, stainless steel sheets can be used for staircase railings. Stainless steel is a durable and corrosion-resistant material, making it suitable for outdoor and indoor applications. Additionally, its sleek and modern appearance adds an aesthetic appeal to staircase railings.

- Q: How do you straighten bent stainless steel sheets?

- To straighten bent stainless steel sheets, there are a few methods you can try depending on the severity of the bend. 1. Cold straightening: For slight bends, you can use a rubber mallet or a hammer to gently tap the bent area back into place. Start from the center of the bend and work your way towards the edges, applying gradual and even pressure. Be careful not to hit the stainless steel too hard, as it may cause further damage. 2. Heat straightening: If the bend is more severe, you can use heat to soften the stainless steel, making it easier to straighten. Start by heating the bent area using a blow torch or a heat gun. Once the stainless steel becomes red-hot, use pliers or a vice grip to carefully straighten the sheet. Keep in mind that this method should only be used for thicker stainless steel sheets, as thinner ones may warp or lose their shape if exposed to excessive heat. 3. Mechanical straightening: This method involves using specialized tools like a hydraulic press or a metal brake to apply controlled pressure and straighten the bent stainless steel sheet. This is recommended for large or heavy-duty sheets that cannot be easily straightened by hand. Ensure that you follow the manufacturer's instructions when using these tools to avoid any accidents. Remember to always wear appropriate safety gear, such as gloves and eye protection, when working with stainless steel sheets. If you are unsure or uncomfortable with straightening the sheets yourself, it is recommended to consult a professional metalworker or a fabrication shop for assistance.

- Q: How do you remove adhesive residue from stainless steel sheets?

- To remove adhesive residue from stainless steel sheets, you can follow these steps: 1. Start by gently scraping off as much of the residue as possible using a plastic scraper or your fingernail. Be careful not to scratch the stainless steel surface. 2. Next, dampen a soft cloth with warm water and mild detergent or dish soap. Gently scrub the adhesive residue using circular motions. Avoid using abrasive cleaners or scrub brushes as they can damage the stainless steel finish. 3. If the adhesive residue persists, you can try using a non-abrasive cleaner specifically designed for stainless steel. Apply a small amount of the cleaner to a soft cloth and gently rub the residue until it lifts off. 4. For stubborn adhesive residue, you can make a paste using baking soda and water. Apply the paste to the affected area and let it sit for a few minutes. Then, use a soft cloth to gently scrub off the residue in circular motions. 5. Rinse the stainless steel sheet thoroughly with warm water to remove any remaining residue or cleaner. 6. Finally, dry the surface with a clean, soft cloth to prevent water spots and streaks. Remember to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will ensure that it doesn't cause any damage or discoloration.

- Q: Are stainless steel sheets suitable for medical equipment or devices?

- Yes, stainless steel sheets are suitable for medical equipment or devices. They possess excellent corrosion resistance, durability, and high strength, making them ideal for use in medical settings. Stainless steel is also easy to clean and maintain, which is crucial for maintaining a sterile environment.

- Q: How do you calculate the bending radius for stainless steel sheets?

- In order to determine the bending radius for stainless steel sheets, several factors need to be taken into consideration. To begin with, the thickness of the stainless steel sheet must be determined. Thinner sheets necessitate smaller bending radii, whereas thicker sheets can accommodate larger radii. The type of stainless steel being used should also be identified. Various grades of stainless steel possess different levels of ductility, which impacts their ability to be bent. Higher ductility allows for smaller bending radii. Furthermore, the desired angle of the bend should be considered. The sharper the angle, the smaller the bending radius required. To calculate the bending radius, the following formula can be utilized: Bending Radius = (2 x Sheet Thickness) + (Bend Angle x Sheet Thickness) For instance, if a stainless steel sheet has a thickness of 0.5mm and a 90-degree bend is desired, the bending radius would be: Bending Radius = (2 x 0.5mm) + (90 x 0.5mm) = 1mm + 45mm = 46mm It is essential to note that this formula serves as a general guideline and may vary depending on the specific properties of the stainless steel being used. Consulting technical specifications or manufacturers' guidelines is always recommended for accurate bending radius calculations.

- Q: Is the cold rolled steel plate good or the stainless steel plate?

- The cold rolled steel itself, whether washed by acid car wash, semi-finished products, or rolled out by cold rolling mill semi-finished products, their rust resistance is very poor. It is easy to oxidize, resulting in rust on the surface of the air. It will not rust until it has been plated with aluminum or zinc, and it is clear that the process is complex and unsafe.

Send your message to us

Stainless Steel 316 sheet and plate with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords