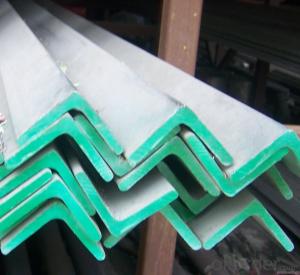

High Quality Stainless angle steel; enqual angle and unequal angle steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offeringHigh Quality Stainless angle steel for Construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High QualityHigh Quality Stainless angle steel for Construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder'sHigh Quality Stainless angle steel for Construction are durable, strong, and resist corrosion. They are newly produeced by good materiales.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of High Quality Stainless angle steel for Construction

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications ofHigh Quality Stainless angle steel for Construction

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery ofHigh Quality Stainless angle steel for Construction

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of High Quality Stainless angle steel for Construction

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the different types of connections used for steel angles in industrial settings?

- Depending on the specific application and structural requirements, steel angles in industrial settings can be connected using various types of connections. Some commonly used connection types include: 1. Welded Connections: When high strength and rigidity are needed, welding is a popular method for connecting steel angles. This involves joining the angles using heat and pressure, resulting in a strong and durable connection. 2. Bolting Connections: Bolts and nuts are used to connect steel angles in this type of connection. It allows for easy assembly and disassembly, making it suitable for applications that require flexibility and adjustability. Bolting connections can be tightened or loosened as needed. 3. Riveted Connections: Metal rivets are used to connect steel angles in this type of connection. It offers good strength and stability and is commonly used in heavy-duty applications. Riveted connections require specialized equipment and skilled labor for installation and removal. 4. Adhesive Connections: Adhesives can be used to bond steel angles together. This type of connection provides good load distribution and is suitable for applications where welding or bolting is not feasible. Adequate surface preparation and adhesive selection are important for ensuring a strong bond. 5. Mechanical Connections: Cleats, brackets, plates, or clips can be used as mechanical connections to connect steel angles. These connections provide flexibility and ease of installation, allowing for adjustments and modifications in the future if necessary. It is important to consider factors such as load-bearing capacity, structural design, safety considerations, and environmental conditions when selecting the appropriate connection type for steel angles in industrial applications. Consulting with structural engineers and following industry standards and codes is crucial to ensure the correct connection type is used.

- Q: What are the different methods of connecting steel angles?

- There are several methods of connecting steel angles, depending on the specific application and desired level of strength and durability. Some common methods include welding, bolting, and using mechanical connectors. 1. Welding: Welding is a widely used method of connecting steel angles. It involves melting the metals at the joint and allowing them to cool and solidify, creating a strong and permanent bond. Welding can be done using various techniques such as arc welding, MIG welding, or TIG welding. It provides a high level of strength and rigidity to the connection. 2. Bolting: Bolting is another common method of connecting steel angles. It involves using bolts, nuts, and washers to secure the angles together. This method allows for easy disassembly and reassembly if needed. Bolts can be tightened to achieve the desired level of tightness and strength in the connection. However, bolting may not offer the same level of strength as welding in certain applications. 3. Mechanical connectors: Mechanical connectors provide an alternative to welding and bolting for connecting steel angles. They are pre-engineered devices specifically designed for connecting steel members. These connectors typically consist of plates, brackets, or clips that are fastened to the angles using bolts or screws. Mechanical connectors offer ease of installation, flexibility, and the ability to accommodate movement and adjustments. 4. Adhesive bonding: Adhesive bonding involves using industrial-grade adhesives to join steel angles together. This method can provide a strong and durable connection, particularly when used in conjunction with mechanical fasteners. Adhesive bonding is often used in applications where welding or bolting may not be suitable or practical. It is important to consider factors such as load-bearing capacity, environmental conditions, and aesthetic requirements when selecting the appropriate method of connecting steel angles. Consulting with a structural engineer or a professional experienced in steel fabrication can help determine the most suitable connection method for a specific project.

- Q: Are steel angles suitable for earthquake-resistant structures?

- Yes, steel angles are suitable for earthquake-resistant structures. Steel is a durable and flexible material that can withstand strong seismic forces. Steel angles provide structural stability and can be used for bracing and reinforcing various components of a building, making them an effective choice for earthquake-resistant construction.

- Q: Are steel angles suitable for rooftop installations?

- Yes, steel angles are suitable for rooftop installations. They are commonly used in construction for their strength and durability. Steel angles provide structural support and can be easily attached to rooftops to secure various installations such as solar panels, antennas, or HVAC equipment.

- Q: Can steel angles be used for support structures in telecommunications installations?

- Steel angles are suitable for support structures in telecommunications installations. They are frequently utilized in construction and engineering due to their robustness and longevity. These angles offer exceptional support and can endure substantial loads and adverse environmental conditions. In telecommunications installations, they are commonly employed for the installation of antennas, satellite dishes, and other equipment. They furnish a steady and secure foundation for the establishment of telecommunications infrastructure, guaranteeing dependable and effective communication networks. Moreover, steel angles can be conveniently tailored and manufactured to meet precise design specifications, making them a flexible option for support structures in telecommunications installations.

- Q: What are the different methods for fastening steel angles?

- Some different methods for fastening steel angles include using welding, bolting, riveting, and using adhesive bonding.

- Q: What is the carbon content of steel angles?

- The carbon content of steel angles may differ based on the particular grade and type of steel employed. Typically, carbon steel angles possess a carbon content that spans from 0.05% to 0.25%. Nevertheless, certain high carbon steel angles can exhibit a carbon content reaching up to 2.1%. The carbon content of steel angles holds significant importance, as it impacts the strength, hardness, and overall characteristics of the steel.

- Q: How do steel angles perform in earthquake-prone regions?

- Steel angles perform very well in earthquake-prone regions due to their inherent strength and flexibility. The angular shape of steel angles provides excellent resistance against lateral forces, making them ideal for seismic applications. When exposed to seismic activity, steel angles can effectively distribute the seismic forces throughout the structure, minimizing the concentration of stress on specific areas. This redistribution of forces helps to enhance the overall structural integrity and prevent catastrophic failure during an earthquake. Additionally, steel angles possess exceptional ductility, allowing them to absorb and dissipate energy through plastic deformation. This ductility helps to prevent sudden and brittle failures, which are common in other materials. Furthermore, steel angles are widely used in seismic design codes and guidelines, ensuring that structures in earthquake-prone regions are built to withstand seismic forces. Overall, steel angles are a reliable and trusted choice for construction in earthquake-prone regions, providing the necessary strength and flexibility to ensure the safety and stability of structures during seismic events.

- Q: Can steel angles be used in the construction of solar panel support structures?

- Indeed, the utilization of steel angles is viable for the establishment of support structures for solar panels. The construction sector frequently utilizes steel angles owing to their robustness and endurance. They offer exceptional support and stability, which are vital aspects for solar panel installations. The fusion or fastening of steel angles can be effortlessly accomplished to form sturdy and inflexible structures capable of enduring the weight of solar panels and the diverse environmental conditions, including wind and snow loads, to which they may be exposed. Furthermore, steel angles can be tailored to meet the precise design prerequisites of the support structure for solar panels, rendering them a versatile option for construction ventures.

- Q: What are the different types of steel angles connections for columns?

- There are several different types of steel angle connections for columns, including the bolted shear plate connection, welded connection, and clip angle connection. Each type of connection has its own advantages and disadvantages, and the choice of connection depends on factors such as the load requirements, design preferences, and ease of installation.

Send your message to us

High Quality Stainless angle steel; enqual angle and unequal angle steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords