Q235B Steel Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000T/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Standards: GB,ASTM,BS,AISI,DIN,JIS

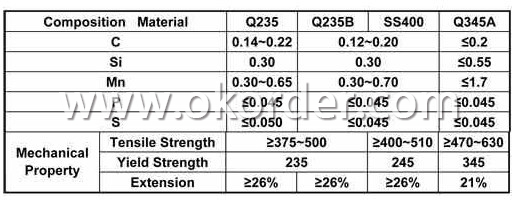

2.Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400; SS540.

3.Length:6m,9m,12m

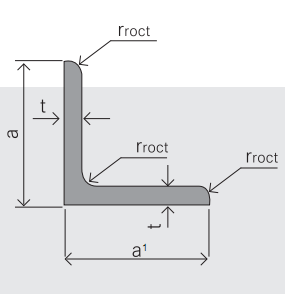

4.Sizes:

|

Sizes: 25mm-250mm | ||

|

a*t | ||

|

25*2.5-4.0 |

70*6.0-9.0 |

130*9.0-15 |

|

30*2.5-6.6 |

75*6.0-9.0 |

140*10-14 |

|

36*3.0-5.0 |

80*5.0-10 |

150*10-20 |

|

38*2.3-6.0 |

90*7.0-10 |

160*10-16 |

|

40*3.0-5.0 |

100*6.0-12 |

175*12-15 |

|

45*4.0-6.0 |

110*8.0-10 |

180*12-18 |

|

50*4.0-6.0 |

120*6.0-15 |

200*14-25 |

|

60*4.0-8.0 |

125*8.0-14 |

250*25 |

5.Material Specifications:

Usage & Applications of Q235B Steel Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Q235B Steel Angle

1.Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2.With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: How do steel angles perform in high-vibration environments?

- Steel angles are well-suited for high-vibration environments due to their excellent structural strength and stability. The inherent properties of steel, such as its high tensile strength and rigidity, allow steel angles to withstand dynamic loads and vibrations without compromising their structural integrity. Steel angles are commonly used in applications such as machinery, construction, and transportation, where vibrations are prevalent. The design of steel angles, with their L-shaped cross-section, also contributes to their performance in high-vibration environments. The right angle shape provides additional support and resistance against bending and torsional forces, making steel angles more resistant to vibrations compared to other materials. This design feature helps to minimize any potential deformation or fatigue that could occur under constant vibrational stress. Moreover, steel angles can be further enhanced to withstand high-vibration environments through surface treatments and coatings. Techniques such as galvanization or painting can provide a protective layer that adds corrosion resistance and prevents degradation of the steel's mechanical properties. This added protection ensures the longevity and durability of steel angles in challenging environments. In summary, steel angles are an ideal choice for high-vibration environments due to their robust nature, L-shaped design, and potential for surface treatments. Their ability to withstand dynamic loads, resist bending and torsional forces, and maintain structural integrity make them reliable and efficient components in various industries where vibration is a concern.

- Q: What is the fire resistance rating of steel angles?

- The fire resistance of steel angles relies on several factors, including the angle's size and thickness, the type of steel employed, and the specific fire protection measures implemented. Steel possesses inherent fire resistance due to its high melting point and low thermal conductivity. Nevertheless, the fire resistance can be improved by applying fireproofing materials, such as intumescent coatings or fire-resistant boards, to the steel angles. By providing insulation and slowing down heat transfer to the steel, these fire protection measures can significantly augment the fire resistance of steel angles. The specific fire resistance rating may differ depending on the thickness and type of fireproofing materials employed. For instance, a steel angle coated with a particular fireproofing substance may have a fire resistance rating of 60 minutes, signifying its ability to withstand fire exposure for up to 60 minutes without compromising its structural integrity. To determine the specific fire resistance requirements for steel angles in a specific application, it is crucial to refer to local building codes, regulations, and fire safety standards. These standards can offer guidance on the necessary fire protection measures and the minimum fire resistance ratings that must be met in different construction scenarios.

- Q: What is the typical corrosion rate of steel angles?

- The typical corrosion rate of steel angles can be influenced by various factors, such as environmental conditions, the type of steel utilized, and the presence of protective coatings. In general, steel angles are prone to corrosion due to their iron content. However, by properly maintaining them and applying protective measures, the corrosion rate can be significantly reduced. In mild atmospheres or indoor settings with low humidity and minimal exposure to corrosive substances, the corrosion rate of steel angles tends to be relatively low, typically ranging from 0.1 to 0.5 mils per year (1 mil equals 0.001 inches). This slow corrosion rate enables steel angles to maintain their structural integrity for a long time. On the other hand, in more aggressive environments like coastal areas with high salt levels in the air or industrial settings with chemical exposure, the corrosion rate can be considerably higher. In these scenarios, the corrosion rate of steel angles can range from 0.5 to 2 mils per year, or even higher. It is crucial in such environments to implement measures such as regular inspection, cleaning, and the application of protective coatings to mitigate the corrosion rate and extend the lifespan of the steel angles. It is important to note that these corrosion rates are estimated averages, and actual rates may vary depending on the specific conditions and factors mentioned earlier. Seeking advice from a corrosion engineer or utilizing corrosion rate data specific to the environment and steel type can provide a more accurate estimation of the typical corrosion rate for steel angles in a particular situation.

- Q: Can steel angles be used in pedestrian bridges?

- Pedestrian bridges can indeed make use of steel angles in their construction. The high strength-to-weight ratio and versatility of steel angles make them a common choice in bridge construction. These angles are frequently employed as structural elements, providing the necessary support, stability, and rigidity to the bridge structure. With their ability to withstand heavy loads and forces, steel angles are well-suited for pedestrian bridges, which must bear the weight of individuals walking across. Moreover, steel angles can be easily fabricated and welded, enabling flexibility in the design and construction of pedestrian bridges. All in all, steel angles are widely favored for constructing pedestrian bridges due to their durability, strength, and user-friendly nature.

- Q: Can steel angles be drilled or punched for fastening?

- Yes, steel angles can be drilled or punched for fastening.

- Q: What is the bending capacity of a steel angle?

- The bending capacity of a steel angle refers to its ability to withstand bending or flexing without breaking or deforming excessively. It is a measure of the angle's structural strength and is typically determined by factors such as the dimensions and thickness of the angle, the type of steel used, and any additional reinforcements or supports present. The bending capacity is usually expressed in terms of the maximum amount of load or stress that the angle can endure before it reaches its yield point, which is the point at which it permanently deforms. The bending capacity of a steel angle can vary widely depending on these factors, and it is crucial to consider this capacity when designing and constructing structures that utilize steel angles to ensure their structural integrity and safety.

- Q: Can steel angles be used in curtain wall systems?

- Yes, steel angles can be used in curtain wall systems. Steel angles are commonly used as support brackets or mullions in curtain wall systems. They provide structural strength and support to the glass panels or other cladding materials. Steel angles can be fabricated in various sizes and shapes to accommodate the specific design requirements of the curtain wall system. Additionally, steel angles can be welded or bolted together to create the desired framework for the curtain wall. Overall, steel angles offer a durable and reliable option for incorporating into curtain wall systems.

- Q: Can steel angles be used for stairs in industrial settings?

- Yes, steel angles can be used for stairs in industrial settings. Steel angles are commonly used in industrial construction due to their strength, durability, and ability to support heavy loads. They provide structural support and stability, making them suitable for staircases in industrial settings where safety and reliability are crucial.

- Q: Can steel angles be used for vehicle frames?

- Yes, steel angles can be used for vehicle frames. Steel angles are commonly used in the construction industry for their structural strength and versatility. They have a wide range of applications, including the construction of vehicle frames. Steel angles provide excellent support and stability, making them ideal for bearing heavy loads and withstanding the various stresses and forces experienced by a vehicle during operation. Additionally, steel angles can be easily welded or bolted together, allowing for flexibility in the design and construction of vehicle frames. Overall, steel angles are a reliable and durable choice for vehicle frames, ensuring the structural integrity and safety of the vehicle.

- Q: How do you determine the appropriate length of a steel angle for a specific application?

- When determining the appropriate length of a steel angle for a specific application, there are several factors to consider. To begin with, it is necessary to assess the structural requirements of the application. This involves analyzing the loads and forces that the steel angle will experience. It is important to determine the maximum load capacity that the steel angle needs to support and ensure that its length can adequately distribute the load without excessive deflection or failure. Next, the dimensions and layout of the application should be taken into account. The available space should be measured and the fit of the steel angle within the overall structure should be determined. Any constraints, such as adjacent components or obstructions, that may impact the length of the steel angle should also be considered. Furthermore, consulting relevant engineering and construction standards is essential. These codes and guidelines provide recommended design values and specifications for steel angles based on their intended use. They can assist in determining the appropriate length based on the application requirements and the material properties of the steel angle. Additionally, it is important to consider the fabrication and installation process. The manufacturing capabilities and limitations should be evaluated, along with any specific requirements for joining or fastening the steel angle. This will help determine if the desired length is feasible and practical in terms of fabrication and installation methods. Lastly, seeking advice from a structural engineer or a qualified professional in the field is advisable. They can provide expert guidance and calculations based on the specific application, ensuring that the chosen length of the steel angle meets all necessary safety and performance requirements. In conclusion, determining the appropriate length of a steel angle for a specific application involves analyzing the structural requirements, considering the dimensions and layout, referring to relevant standards, evaluating fabrication and installation processes, and seeking professional guidance when required.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; middle east; South Korea; Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30%-45% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

Q235B Steel Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000T/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords