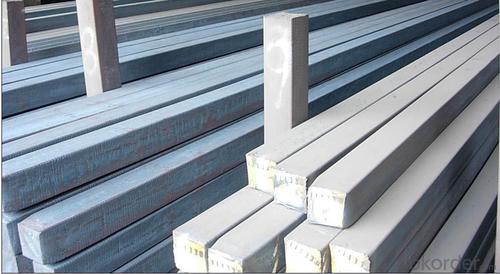

Square Steel Billet Q235 Grade Prime Quality 8#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 8#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 8#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 8#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 8#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 8#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Are there any international standards for steel billets?

- Yes, there are international standards for steel billets. The International Organization for Standardization (ISO) has developed several standards that define the requirements and specifications for steel billets. The most commonly used ISO standard for steel billets is ISO 683-2, which specifies the technical delivery requirements for hot-rolled steel bars, sections, and billets for general engineering purposes. Additionally, the American Society for Testing and Materials (ASTM) has also developed standards for steel billets, such as ASTM A615/A615M, which specifies the requirements for deformed and plain carbon-steel bars for concrete reinforcement. These international standards ensure that steel billets produced and traded globally meet the necessary quality and performance criteria, promoting consistency and compatibility in the industry.

- Q: What are the main factors affecting the heat resistance of steel billets?

- There are several main factors that can affect the heat resistance of steel billets. Firstly, the chemical composition of the steel plays a crucial role. Elements such as carbon, chromium, and nickel can enhance the heat resistance of steel by forming stable oxide layers on the surface that act as a protective barrier against high temperatures. Additionally, the presence of alloying elements like molybdenum and vanadium can also improve the heat resistance of steel by increasing its hardenability and reducing grain growth during heat treatment. Another important factor is the microstructure of the steel. Fine-grained structures tend to have higher heat resistance due to their increased strength and reduced susceptibility to thermal fatigue. Heat treatment processes like quenching and tempering can also alter the microstructure and improve the heat resistance of steel billets. The rate of heating and cooling also affects the heat resistance of steel. Rapid heating or cooling can lead to thermal shock and result in the formation of cracks or distortion in the billets. It is essential to control the heating and cooling rates to minimize these detrimental effects and maintain the desired heat resistance. Furthermore, the presence of impurities or defects within the steel can significantly impact its heat resistance. Inclusions, such as sulfur, phosphorus, and non-metallic oxides, can act as stress concentrators and reduce the heat resistance of steel. Similarly, internal defects like voids, cracks, or segregation regions can promote crack initiation and propagation during thermal cycles, thereby reducing the overall heat resistance of the steel billets. Lastly, the mechanical properties of the steel, such as its tensile strength, hardness, and ductility, can influence its heat resistance. Higher strength and hardness can generally enhance the heat resistance, while excessive ductility may lead to deformation or failure under high-temperature conditions. In summary, the main factors affecting the heat resistance of steel billets include the chemical composition, microstructure, rate of heating and cooling, presence of impurities or defects, and the mechanical properties of the steel. Understanding and optimizing these factors can help in producing steel billets with improved heat resistance for various applications.

- Q: Can steel billets be used in the production of medical equipment?

- Yes, steel billets can be used in the production of medical equipment. Steel is known for its strength, durability, and resistance to corrosion, making it an ideal material for manufacturing various medical devices. Steel billets, which are the initial semi-finished product of steel production, can be further processed and shaped into specific components or parts required for medical equipment. These components can include surgical instruments, implants, orthopedic devices, needles, and other medical tools. Steel's mechanical properties and ability to withstand sterilization processes make it a suitable choice for producing safe and reliable medical equipment.

- Q: How do steel billets contribute to the overall durability of a product?

- Steel billets play a crucial role in elevating the overall durability of various products, and their contribution cannot be overstated. These semi-finished steel products serve as raw material for further processing in industries such as construction, automotive, and manufacturing. A key factor in the enhanced durability provided by steel billets is their superior strength and toughness. Steel is renowned for its exceptional mechanical properties, including high tensile strength and resistance to deformation, making it an optimal choice for applications that require durability. By utilizing steel billets as the initial material, manufacturers can guarantee that the final product will possess the necessary strength to endure heavy loads, impacts, and external forces. Additionally, steel billets exhibit outstanding corrosion resistance. With proper processing and treatment, steel can withstand rust and other forms of corrosion caused by moisture, chemicals, or environmental factors. This corrosion resistance significantly enhances the durability of the end product by preventing degradation and extending its lifespan. Another advantage of employing steel billets lies in their versatility for customization. Manufacturers can shape and form the billets into various sizes and dimensions to meet the specific requirements of the product. This flexibility enables the production of components that fit together perfectly, reducing the risk of weak points or vulnerabilities in the overall structure. Furthermore, steel's malleability and ductility allow for easy molding and welding, further enhancing the overall strength and durability of the final product. Furthermore, steel billets undergo stringent quality control measures during the manufacturing process. These measures ensure that the billets meet rigorous industry standards and specifications, guaranteeing their reliability and consistency. The utilization of high-quality steel billets, in turn, contributes to the overall durability of the product by providing a sturdy and dependable foundation. In conclusion, steel billets play a pivotal role in enhancing the overall durability of products. Their exceptional strength, corrosion resistance, versatility, and high-quality attributes make them an optimal choice for industries that prioritize durability. By utilizing steel billets as the raw material, manufacturers can create products capable of withstanding demanding conditions, ensuring longevity and customer satisfaction.

- Q: Are steel billets used in the production of household appliances?

- Indeed, steel billets find application in the manufacturing of household appliances. Serving as intermediate steel products, steel billets are employed as primary materials across various industries, encompassing the production of household appliances. Following the process of heating, these billets are either rolled or forged into diverse forms and dimensions, thereby fabricating essential components such as sheets, plates, rods, and bars, pivotal in the creation of appliances. Steel, due to its robustness, longevity, and ability to resist corrosion, becomes a favored choice in the realm of household appliances. Consequently, steel is extensively utilized in the production of a wide array of household appliances, including refrigerators, washing machines, dishwashers, ovens, and several others.

- Q: What are the specifications for alloy steel billets used in the defense industry?

- The specifications for alloy steel billets used in the defense industry vary depending on the specific application and requirements of each project. However, there are certain common specifications that are typically followed. Firstly, the alloy steel billets used in the defense industry must meet stringent material standards and be certified to specific military or industry specifications. These standards often include requirements for the chemical composition, mechanical properties, and heat treatment of the alloy steel. The chemical composition of the alloy steel billets is crucial, as it determines the material's strength, hardness, and resistance to corrosion and high temperatures. The specific composition may vary depending on the intended use, but common alloying elements include chromium, molybdenum, vanadium, and nickel. Additionally, the carbon content is carefully controlled to achieve the desired strength and toughness. In terms of mechanical properties, alloy steel billets for defense applications generally need to have high strength, toughness, and impact resistance. They should be able to withstand extreme conditions, including high pressure, shock, and vibrations. The billets may undergo specific heat treatments, such as quenching and tempering, to achieve the desired mechanical properties. The dimensional specifications for alloy steel billets used in the defense industry are also crucial. They must meet precise size and shape tolerances, as well as surface finish requirements, to ensure compatibility with the manufacturing processes and final products. Furthermore, the billets may need to be certified to specific industry or military standards, such as MIL-STD or ASTM specifications, to ensure their suitability and reliability for defense applications. These standards define the testing methods, quality control requirements, and performance criteria that the alloy steel billets must meet. Overall, the specifications for alloy steel billets used in the defense industry encompass a range of factors, including chemical composition, mechanical properties, dimensional tolerances, and adherence to industry or military standards. These specifications are essential to ensure the performance, durability, and safety of the final defense products.

- Q: Can steel billets be used in the production of automotive components?

- Yes, steel billets can be used in the production of automotive components. Steel billets are raw, semi-finished steel products that can undergo further processing, such as rolling, forging, or machining, to create various automotive parts like engine blocks, suspension components, gears, and more. The use of steel billets allows for the production of high-strength and durable automotive components, making them a popular choice in the automotive industry.

- Q: Can steel billets be used in the production of consumer electronics?

- No, steel billets are primarily used in the production of construction materials and machinery, rather than consumer electronics which typically require more specialized materials such as semiconductors, plastics, and alloys.

- Q: What are the main factors affecting the weldability of steel billets?

- The main factors affecting the weldability of steel billets include the composition of the steel, the presence of impurities, the presence of alloying elements, the size and shape of the billets, and the heat treatment of the steel.

- Q: How do steel billets contribute to the overall durability of a structure?

- The construction industry heavily relies on steel billets, which play a vital role in enhancing the durability of structures. To create these billets, molten steel is cast into a solid form and then further processed into various shapes and sizes for construction projects. Steel billets contribute to the durability of a structure primarily through their strength and ability to bear heavy loads. Steel has an exceptional strength-to-weight ratio, meaning it can withstand significant loads and stresses without compromising its structural integrity. When used in construction, steel billets provide the necessary strength to support the weight of the entire structure, ensuring it can withstand various environmental and operational factors for an extended period. In addition, steel billets offer excellent corrosion resistance, making them ideal for structures exposed to moisture, humidity, or harsh weather conditions. Steel is inherently resistant to rust and other forms of corrosion, ensuring the structure remains intact and structurally sound over time, reducing the need for frequent maintenance and repairs. Steel billets also have the ability to withstand extreme temperatures due to their high melting point. This property is especially crucial for structures in high-temperature environments, such as industrial facilities or buildings near fire-prone areas, as it ensures their safety and longevity. Moreover, steel billets enhance the overall resilience of a structure against external forces like earthquakes or strong winds. Steel's high elasticity and ductility allow it to absorb and dissipate energy more effectively than other materials, reducing the risk of structural failure during seismic events or extreme weather conditions. In conclusion, steel billets contribute to the durability of structures in various ways. Their strength, load-bearing capacity, corrosion resistance, ability to withstand extreme temperatures, and resilience against external forces make them an ideal material for constructing long-lasting and robust structures. By incorporating steel billets into construction projects, engineers can ensure the durability and safety of structures for many years.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 8#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords