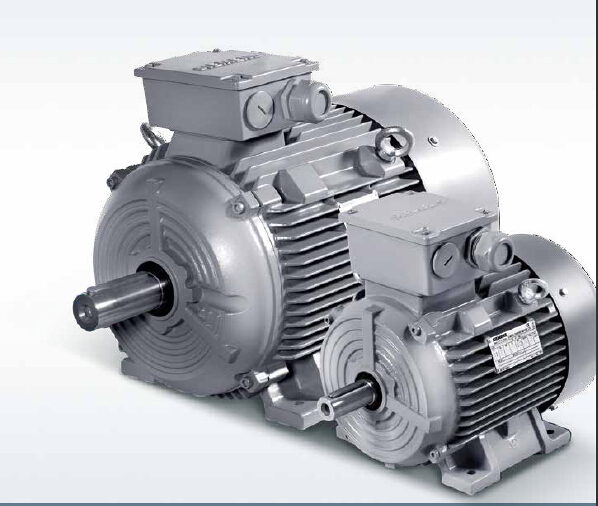

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Soooo... my outside condensor fan has started making this LOUD squealing noise... its like the noise you hear sometimes when it starts up... but it doesn't stop, and gets louder and Louder..like grinding metal.. and it only happens in the winter time when it gets below 45 degrees (F) or so... it works perfectly fine in the summer... The fan spins good and come on fine.. its just the noise..... So what i'm trying to figure out is ... is it the Motor.... or the Fan blades... because the motor is spinning the blades just fine...and with my research i found that when bad fan blades get wet they make a squealing noise..so i thought maybe the same applys with the cold...... or is it the motor with some bad barrings or something... any help??...thanks

- need to remove , and check for lose parts on blade, check bearings to see if any slap in bearings, if so replace, if old and bad blade, should replace motor with it.

- Q: without adding any gearing or uping on the size,wattage, etc.

- No, not really. As with any motor, you are going to get X power out for Y power in. Power in is electrical wattage, and power out is mechanical wattage (or horsepower). Electrical power is volts times amps, and mechanical power is speed times torque. You can't get more power out- increasing the torque- without more power in. The only practical way to do this would be to feed the motor more power (in the form of voltage), but that would increase your power consumption, increase your speed, and you're not likely able to get a higher AC voltage very easily.

- Q: My outdoor ac unit stop working a few weeks ago.. pressor is running but fan is not. I turned the unit off until it cooled down and turned it back on and the fan still didn't spin.I then gave it a spin with a stick and it started right up. This has happened twice now. I think the ac motor just needs lubricating but I don't know how/where to lubricate. Please help.

- Yep you need a new capacitor. unfortunatly who ever you hire will charge around $150 to change it, 80 just to look at it

- Q: also when working in generator mode, what type of current is generated ac or dc???

- AC Current is used to propel the brushless DC motor. The DC current you're supplying is converted to AC current by its circuitry to create an oscillating magnetic field. This oscillating magnetic field in the stator interacts with the permanent magnet in the rotor, causing it to rotate. In generator mode, AC current is generated.

- Q: How does an electric (AC) motor work?

- This is a huge question and I don't know how much detail you want or how much you've had the education to understand, so I'll be general. First a few basic concepts: Current flowing through a wire causes a magnetic field to be generated. Magnetic fields influence each other to move. Alternating current reverses polarity with each cycle. One simple type of electric motor consists of two fixed magnets and a coil of wire wrapped around a central shaft. The coil of wire becomes an electromagnet when an electric charge is applied to it. This then generates a magnetic field. The coil and the shaft it is attached to begin to rotate due to interactions with the two fixed magnets. This rotating shaft is the basis of the electric motor. There are many more details which you could learn if you want to do more research. There are many more complicated motor designs. An electric generator is the opposite of what was just described--physical rotation causes an output of electric energy. If you want a more detailed understanding of the fundamental forces involved, I would suggest taking an electromagnetic field physics class. Or if you just want to learn more about motors get one and tear it apart! Reverse engineering is the best way to truly understand how something works.

- Q: hey i have four questions for yas most apprieciated if you can help!!!Question 1Where does the energy that makes the DC electric motor work originally come from?Question 2What difficulties would you have measuring the current flowing through a DC electric motor when it is operating?Question 3Please Explain how you would calculate the resistance (in ohms) of a DC electric motor circuit.Question 4PLease name as many appliances that have electric motors in themplease and thank-you if ya answered!!! PEACE OUT :D

- 1) Are you asking how does a DC electric motor produce energy? The simple answer is that by changing a magnetic field around a coil of wires, you induce an electric field. Inside of a conductive piece of wire an electric field will push on electronic particles (like electrons and protons) and force them to drift towards the area of lowest (or highest depending on the particle) area of potential energy. Theres quite a bit of calculus involved in a better explanation though. 2) Well practically it would be near impossible to go near an electric DC motor while in operation. Essentially is a big coil of wires with magnets spinning around it. Aside from being shocked, I dont think you could get close enough to do any type of measurements with a DMM. 3) I suppose your asking how to calculate the internal resistance of a device. There are several ways to do this, depending on how much you know about circuits. One way is to apply a known load to a circuit and measure the voltage drop across it. You can then do a bit of voltage division and come up with an easy answer. This is due to something called the loading effect which basically says that as the load on a circuit increases the effect of the internal resistance of a source (dc motor) decreases. 4) I'm sure you can figure this one out.

- Q: Is it possible that i could start a fire or something? I took an old plug and connecting the motor wires to it, then i hooked the plug to the mains socket, it starts quite a big spark when it turns on, but should it be safe? even if the plug is well covered in its insulation?

- You can always connect the motor to the mains, but ONLY through a AC Motor Starter of proper rating matching the motor. Ordinary switches and plug tops are not designed to handle high inductive loads. Since the motor is an inductive load, switching it on with an ordinary switch or plug will definitely create a spark. The spark is caused due to arcing between the contacts (due to back emf or inductive kickback) can be a potential shock hazard to the user. If the spark latches on to something combustible, then there is also a fire hazard. If you use it regularly, the spark will erode the contacts leading to failure of switch/plug So use a properly rated AC Motor Starter which is designed to avoid the above problem. An additional bonus is that the starter will have a thermal relay which will protect your motor and electrical wiring in case of overload due to load, bearing failure, rotor jam etc.

- Q: My motor draws 24VDC / 5A and runs off a lead acid battery. If I input 120VAC / 15A in a ACgt;DC power supply what does it out have to be to run the motor? I've been told an output of 24VDC / 5A is not enough.

- Dear, Thank you, am also fine like you then dear based on application of precision select drive i.e. scr control drive also used but for variable speed drive else put transformer bridge rectifier without use filtering capacitor by put of current limit resistor suitable for 5a its wattage. Use secondary of transformer is 27v,7.5a

- Q: how to reduce single phase AC motor speed?

- There is no method to do this. This is an induction motor. A VFD (Variable Frequency stress) is not going to work as introduced up by way of lunchtime_browser. You're going to have received to use a gearbox with nearly any motor to do that. When you use an induction motor (squirrel cage or AC motor), it's feasible to control a 3 part motor to reduce speeds with the help of utilising a VFD, that reduces the voltage and modifications the frequency, however most effective inside limits. These can also be programmed to a constant velocity, nevertheless no longer so gradual as 100 and twenty RPM. The cooling could additionally have received to be addressed (fan too sluggish). Single phase (reduce up phase) motors are further restricted, whether or not or no longer making use of a centrifugal switch or no longer. You most often desire a DC motor in case you occur to insist on no gearbox. The variable percent controller to swimsuit this motor is just set to the speed you wish to have. If you want a designated speed it desires a velocity controller with p.C. Sensor and feedback. Be aware that the mechanical energy is the constructed from RPM and torque. The torque is variety of the equal, as it's decided through the present ranking. Nonetheless with a hundred and twenty RPM from a 1440 RPM motor the pace is just one/12 so the power is only 1/12. Utilizing a gearbox increases the torque and reduces the percent so the energy is more or less the identical. There are gearmotors for a large variety of output RPM. A bicycle hub motor could suit if the power is to your form. One more proposal is a stepper motor, which can run at these low speeds, however it does want a controller (driver) and vigor provide..

- Q: i have the following specifications for an ac motor with a built in constant torque drive.10:1 constant torque3600rpm250HPWhat Does the ratio mean?

- Check okorder /

Send your message to us

Siemens ILE0001 Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords