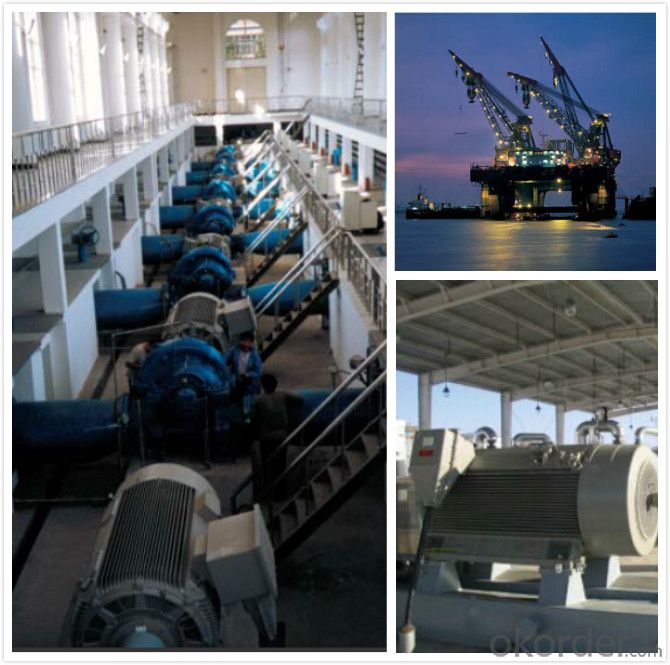

Siemens High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q: The other night my ac was making a noise like something was in there, we checked and surprisingly there was a dead snake in my car's ac motor. We took it out, found out how it got in there and fixed that problem... but since we found the snake, a rancid smell has been in my car,(especially when the ac is on). I tried putting baking soda and air freshener in my car but the smell isn't going away... any ideas on how to get rid of the odor?

- what car do you own? is it 1996+? if it is, try figuring out if you have a cabin air filter, if so, replace it

- Q: Why don't AC motors use commutators?

- The principle of AC motor of DC motor is differentDC motor running by permanent magnet and coil production function to promote Miguel rotor, reversing to coil rotor 180 degrees (equivalent to the magnetic field direction 180 degrees) to maintain the current direction of the coil and the existing magnetic field to produce the correct momentAlternating current machines operate with rotating magnetic fields, rotating magnetic fields depend on the direction of the current, and alternating current has this property, so there is no need for commutatorHowever, this is not absolute, the DC motor can also use no commutator, AC can also use the commutator, and fixed rotor design relatedThe AC motor is used for excitation, that is, the magnetic field is provided to allow the coil to cut the magnetic field lines

- Q: I have a large AC motor, and a small DC one. The DC motor generates electricity for a small light, and I was wondering if an AC motor could do the same. Oh, and by the way, for those of you that say motors can't generate electricity, I know from experience that a DC one in reverse can.

- Reverse Ac Motor

- Q: I am in an engineering team and I am supposed to do research on an engine that is suitable to make the car we are building (Factory Five GTM Supercar) go at 150mph. It is going to be run on batteries and have the electric engine to power it. Where can I find a165KW 3 phase AC induction motor?

- This okorder /

- Q: I used to understand this stuff pretty good, now I can only remember enough to be dangerous. Basically, I have a motor turning at about 340 RPM. It pulls 8 amps at 110 VAC. I want to incorperate a resistor into the circuit to reduce the speed by half (at least), so I know I have to reduce the POWER to the motor (currently 880 watts), but here where I get confused. If I throw in a resistor, will it just pull more amps, or will it slow it down proportionately? I'm stuck trying to re-teach myself ohm's law. So if R=V/I, then in my case R= 110/8 = 13.75so does that mean I already have 13.75 ohms of resistance, or that's how much I need to reduce the voltage to 0?Could someone walk me through this and help me calculate how much resistance I would need to reduce the speed by half? I sould mention it's a reversable motor with a capacator (if that matters, I don't know).

- “motor turning at about 340 RPM” Are you sure? Is that after some pulleys or gears that are reducing the speed? An AC motor turning at 340 RPM would be a very unusual motor. If you already have pulleys or gears, that is what you need to change. It is difficult to change the speed of an AC motor unless it is a universal motor, really a DC motor with a commutator running on AC. If the motor has a capacitor, it is probably an induction motor that uses the capacitor for starting. Many such motors are designed to switch off the starting circuit when the motor reaches full speed. If you do something to reduce speed, the starting circuit will overheat. Another answer points out that inserting a resistor will reduce the torque. If the load is a centrifugal pump or a fan, reducing torque probably reduce the speed to a slower stable operating speed. Most other types of loads require about the same torque at lower speeds and may only slow down a little until the resistance in increased to the point that the motor stalls. Reducing the voltage with a light dimmer type device will have the same effect. Even with a fan or pump load, slowing a motor by reducing the voltage may cause the motor to overheat unless the motor is designed for that duty. If the load is a fan or pump and if the capacitor is not switched off when the motor reaches full speed, there are electronic frequency changers called variable frequency drives (VFDs) that can be used, but they are rather expensive.

- Q: Im trying to power a hobby servo motor (HSR-5995TG ) from the wall using a standard 7.5V 1amp adapter... What do I need to power the motors sufficiently without frying the motors or myself?

- I would change the stupid subjective so-called guidelines they have. They don't violate all the same kinds of questions, they violate the person writing them. then they won't tell you specifically why they deleted a question. Here's an example: So ladies now that summer is about here are you looking forward to getting out your swimsuits? What is your favorite style and color? Now why in the hell is this a violation and then the cowards wouldn't even tell me why it was. Yahoo sucks for sure

- Q: Rating of an ac motor?

- look on the metal plate on side of motor or a sticker based on the simple and vague info thats all i can suggest

- Q: I'm looking for a right angled dual shaft AC motor around 3hp, preferably geared. Any idea where I could find one?

- If you want the motor directly mounted to the gear box, you want a C flange style gearbox and a C flange style matching motor.

- Q: Do we need constant frequency and constant voltage for AC motor forrunning it at constant speed?

- I would assume so, DC motors when the voltage is lowered the motor slows. If you're in the US your ac supply is going to be 60hz unless you're modifying it.

- Q: I think it's the coil, but I can't remember why. I think it has to do with the more surface for current to travel, but I can''t remember. Any help?

- The simple motor tries to reach an output speed proportional to applied voltage. So the battery is the no. 1 influence on speed. The motor actually generates a back EMF when running (that's how it approaches a speed proportional to voltage; the lower the speed the lower the opposing EMF so the more current flows). Interestingly, a weaker magnet, or fewer windings in the coil, will also make the motor run faster; it has to in order to make the same back EMF. So both could be considered secondary influences on speed. EDIT: The AC requirement changes things. First, there's no battery. The simplest AC motor I can think of is an eddy-current motor, with an AC stator and a simple single-conductor rotor (e.g., a solid cylinder), a reduced version of the single-phase induction motor, whose rotor has either conducting coils or a squirrel-cage design with several conducting bars. The primary no-load speed influence is the AC frequency; the field strength and coil area affect torque. The next simplest AC motor I can think of is a synchronous type; AC on the stator coil and a permanent-magnet rotor. As long as it runs at all, it runs at synchronous speed determined by the AC frequency, e.g., 3600 rpm for 60 Hz and a dipole rotor. Assuming it's running with no load, changes in magnet strength or coil turns or current either stop it or don't affect its speed.

Send your message to us

Siemens High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords