Sheets of 3/4 Thick Continuous Casting Aluminium Coil for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

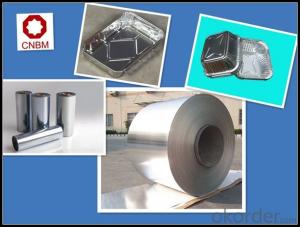

1.Structure of Continuous Casting Aluminium Coil for Building

Continuous Casting Aluminium Coil for Building is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coil for Building

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1500MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How do you ensure the surface quality of aluminum sheets?

- To ensure the surface quality of aluminum sheets, several measures can be taken: 1. Cleaning: Before any surface treatment or inspection, it is essential to thoroughly clean the aluminum sheets to remove any dirt, grease, or other contaminants. This can be done with solvents, detergents, or specialized cleaning agents. 2. Visual Inspection: Conduct a visual inspection of the surface for any visible defects like scratches, dents, or pitting. This can be done by trained personnel using proper lighting and magnification tools. 3. Chemical Treatment: Depending on the desired surface finish and application, aluminum sheets may undergo chemical treatments like anodizing, chromate conversion coating, or passivation. These processes can enhance the surface quality, corrosion resistance, and aesthetic appearance of the sheets. 4. Mechanical Polishing: Mechanical polishing techniques such as grinding, buffing, or sanding can be employed to remove surface imperfections and achieve a smooth, glossy finish. Care should be taken to ensure consistency and avoid over-polishing, which can compromise the sheet's integrity. 5. Coating and Protecting: Applying protective coatings like lacquers, paints, or powder coatings can further enhance the surface quality, appearance, and durability of aluminum sheets. These coatings act as a barrier against corrosion, abrasion, and environmental factors. 6. Quality Control: Implementing rigorous quality control procedures throughout the manufacturing process is crucial. This includes regular inspections, testing, and documentation to ensure that the surface quality of aluminum sheets meets the required standards and specifications. 7. Handling and Packaging: Proper handling and packaging during transportation and storage are essential to prevent any surface damage. Adequate protective measures such as using protective films, paper interleaves, or cushioning materials can be employed to safeguard the surface quality until the sheets reach their final destination. By following these measures, manufacturers can ensure the surface quality of aluminum sheets, meeting the desired specifications and customer expectations.

- Q: How much is the price of the 6061 aluminum plate?

- You ask the question is not detailed enough, because 6061 aluminum thick and thin prices are different, domestic and imported prices are different, domestic quality of different prices are also different.

- Q: Can aluminum sheet be used for automotive heat shields?

- Indeed, aluminum sheet is a suitable option when it comes to automotive heat shields. The automotive industry favors aluminum due to its impressive thermal conductivity and remarkable heat resistance. By reflecting and dispersing heat away from specific regions, it effectively safeguards delicate components from excessive temperatures. Moreover, aluminum possesses the advantages of being lightweight and resistant to corrosion, rendering it an optimal choice for automotive purposes. It finds widespread utilization in diverse heat shield configurations, encompassing exhaust, engine, and under-carriage heat shields.

- Q: What are the different types of finishes used for decorative aluminum sheet?

- Decorative aluminum sheet can be enhanced and protected with various types of finishes. Here are some of the most common finishes available: 1. Mill finish: This is the standard finish when aluminum sheets come directly from the mill. It has a smooth, shiny appearance without any additional treatments or coatings. 2. Anodized finish: By undergoing an electrochemical process, a durable, corrosion-resistant layer is created on the aluminum surface. Anodized finishes can be clear or colored, giving the sheet a decorative, matte look. 3. Brushed finish: Also referred to as satin finish, this finish involves brushing the aluminum sheet with a fine abrasive material to produce fine lines or scratches. It results in a textured, non-reflective surface that conceals imperfections. 4. Polished finish: This finish includes polishing the aluminum sheet using a series of abrasive materials to achieve a smooth, reflective surface. It creates a shiny, mirror-like appearance, often utilized for decorative purposes. 5. Painted finish: Aluminum sheets can be coated with various types of paints to achieve different colors and finishes. These coatings can be applied through methods like powder coating, liquid painting, or coil coating, offering both decorative and protective advantages. 6. Embossed finish: This type of finish involves pressing a pattern or design onto the aluminum sheet, creating a three-dimensional surface. Embossed finishes can vary in depth and detail, adding texture and visual interest to the sheet. These examples demonstrate the variety of finishes available for decorative aluminum sheet. Each finish offers its own distinct appearance and benefits, allowing for a wide range of design options.

- Q: How does the surface treatment of aluminum sheet affect its appearance?

- The surface treatment of aluminum sheet can greatly affect its appearance. Different treatments such as anodizing, coating, or polishing can alter the texture, color, and shine of the aluminum surface. Anodizing can create a protective oxide layer while also providing a range of colors. Coatings can add a layer of paint or protective film, giving the aluminum a smooth or textured finish and providing various color options. Polishing can enhance the reflectivity of the aluminum, giving it a shiny and mirror-like appearance. Overall, the surface treatment plays a crucial role in determining the final look and visual appeal of the aluminum sheet.

- Q: What is the minimum bending radius for aluminum sheets?

- The minimum bending radius for aluminum sheets depends on the thickness and grade of the aluminum. However, as a general guideline, it is recommended to have a minimum bending radius of 1.5 times the thickness of the aluminum sheet.

- Q: What are the different methods of surface protection for aluminum sheet?

- Some of the different methods of surface protection for aluminum sheet include anodizing, powder coating, painting, and laminating. Anodizing involves creating a protective oxide layer on the surface of the aluminum, which provides corrosion resistance and enhances its appearance. Powder coating involves applying a dry powder coating to the aluminum sheet and then curing it through heat, creating a durable and protective finish. Painting is another method where a liquid paint is applied to the surface of the aluminum sheet, providing both protection and aesthetic appeal. Laminating involves bonding a protective film or sheet onto the surface of the aluminum, offering resistance against scratches, abrasion, and chemical damage. These methods help to preserve the quality and longevity of the aluminum sheet in various applications.

- Q: Can the aluminum sheets be used for architectural cladding?

- Indeed, architectural cladding can make use of aluminum sheets. Owing to its lightweight properties, durability, and versatility, aluminum remains a favored selection for cladding purposes. Its pliability and ability to assume diverse forms make it ideal for a broad spectrum of architectural designs. Furthermore, aluminum boasts corrosion resistance, ensuring its longevity as a cladding option. Moreover, the possibility of coating aluminum in various finishes enables customization to align with the desired aesthetic of the structure. All things considered, aluminum sheets emerge as a dependable and pragmatic choice for architectural cladding.

- Q: Is it possible to incorporate recycled aluminum windows into a construction or renovation project?

- <p>Yes, you can use recycled aluminum windows in your project. Recycled aluminum windows are not only environmentally friendly but also offer similar performance to new aluminum windows. They are durable, lightweight, and maintain good thermal efficiency. When selecting recycled aluminum windows, ensure they meet the required quality standards and are suitable for your project's specifications. It's also important to consider the condition of the windows and any necessary refurbishment or maintenance they might require.</p>

- Q: Can aluminum sheets be embossed?

- Indeed, it is possible to emboss aluminum sheets. The act of embossing entails producing a design that is elevated or inset on the surface of a material. Aluminum is a versatile substance that can be easily manipulated, including being subjected to embossing. One can employ different techniques in order to emboss aluminum sheets, such as heat embossing or using tools and machines specifically designed for embossing. By undergoing the embossing process, the aluminum sheets gain texture and depth, resulting in an enhanced appearance suitable for a wide range of applications. These applications may include decorative purposes, signage, nameplates, and even the addition of texture to automotive or architectural accents.

Send your message to us

Sheets of 3/4 Thick Continuous Casting Aluminium Coil for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords