Decorative 1/4 Aluminum Strips Coated Coil/Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: fascia, shop fronts...

3. Feature of Aluminum

Aluminium foil, even when it is rolled to only 0.007 mm thickness, is still completely impermeable and lets neither light aroma nor taste substances out. Moreover, the metal itself is non-toxic and releases no aroma or taste substances which makes it ideal for packaging sensitive products such as food or pharmaceuticals

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

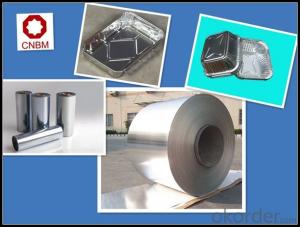

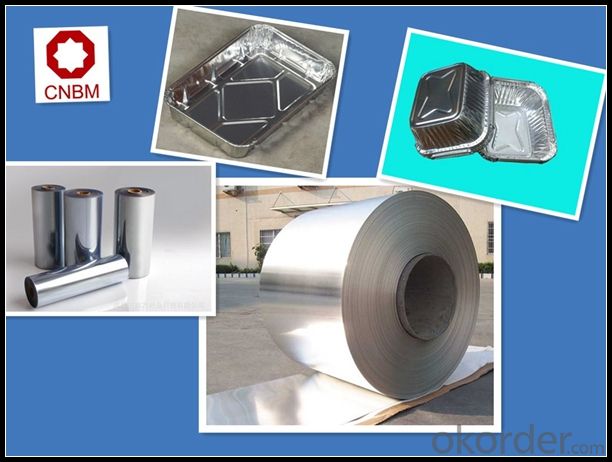

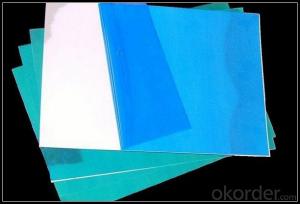

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks for a comparison between two types of siding materials: aluminum and steel. It seeks to understand the distinct characteristics that set these two materials apart.

- <p>Aluminum and steel siding are both popular choices for exterior cladding, but they have several differences. Aluminum is lightweight, corrosion-resistant, and requires minimal maintenance, making it ideal for coastal areas. It also comes in a variety of colors and finishes. Steel siding, on the other hand, is more durable and can withstand harsh weather conditions. It is heavier and stronger than aluminum, but it may require more maintenance, such as painting or coating to prevent rust. Steel is also more energy-efficient due to its insulating properties. Both materials offer different benefits and are suitable for different applications based on the climate, design preferences, and budget.</p>

- Q: Is it good to drive a wheeled excavator or an aluminum belt?

- Wheeled as if driving a car, the aluminum belt seems to open tanks.

- Q: Is it possible to utilize aluminum strips instead of conventional siding materials in areas with high temperatures?

- <p>Yes, aluminum strips can be used to replace traditional siding materials in hot climates. Aluminum is a lightweight, durable, and corrosion-resistant material that can withstand high temperatures. It reflects heat, reducing the amount of heat absorbed by the building, making it a suitable choice for hot climates. Additionally, aluminum siding is low maintenance and can be easily painted or finished to match the desired aesthetic. However, it's important to consider factors such as insulation properties and potential for condensation, as aluminum may not insulate as well as some other materials.</p>

- Q: This question asks for a method to determine the weight of a specific length of aluminum strip.

- <p>To calculate the weight of a certain length of aluminum strip, you need to know the strip's length, width, thickness, and the density of aluminum. The density of aluminum is approximately 2700 kg/m鲁. The formula to calculate the weight is: Weight = (Length 脳 Width 脳 Thickness 脳 Density) / 1000. Convert all measurements to consistent units (SI units are preferred). For example, if you have a strip that is 1 meter long, 0.01 meters wide, and 0.001 meters thick, the weight would be calculated as follows: (1 脳 0.01 脳 0.001 脳 2700) / 1000 = 0.027 kg.</p>

- Q: Is it possible to create a more energy-efficient roof using aluminum strips compared to other materials?

- <p>Yes, aluminum strips can be used to create a roof that is more energy-efficient than some other materials. Aluminum is a good conductor of heat, which can help in reflecting sunlight and reducing heat absorption, thus lowering cooling costs. Additionally, aluminum roofs can be designed with energy-efficient features such as solar reflectance and thermal emittance properties, which can further enhance their energy efficiency. However, it's important to consider the overall design, insulation, and installation quality to maximize energy efficiency.</p>

- Q: The user is inquiring if it's possible to utilize recycled aluminum for their roofing project.

- <p>Yes, you can use recycled aluminum for your roofing project. Recycled aluminum is not only environmentally friendly but also cost-effective. It retains the same strength and durability as new aluminum, making it an excellent choice for roofing. It's lightweight, resistant to corrosion, and can be easily shaped and installed. Additionally, using recycled aluminum helps reduce waste and conserves natural resources. However, it's important to ensure that the recycled material meets quality standards and is sourced from a reputable supplier to guarantee its performance and longevity.</p>

- Q: What types of aluminum strips are known for their durability?

- <p>Yes, there are several types of aluminum strips known for their durability. One of the most durable types is 7075 aluminum, which is an alloy that offers high strength and is commonly used in aerospace applications. Another durable option is 6061 aluminum, which is a heat-treatable alloy with good mechanical properties and is often used in construction and transportation. Additionally, 3003 aluminum is known for its corrosion resistance and is used in applications where durability against weathering is important. The durability of aluminum strips can also be enhanced through various surface treatments and coatings.</p>

- Q: What types of aluminum strips are more appropriate for commercial use?

- <p>Yes, there are specific types of aluminum strips that are more suitable for commercial applications. These include 1100 series aluminum strips, known for their high purity and excellent formability, making them ideal for general commercial purposes. 3003 series aluminum strips are also popular due to their enhanced corrosion resistance and formability, suitable for applications requiring moderate strength and good workability. Additionally, 5052 series aluminum strips offer good corrosion resistance and weldability, making them suitable for applications in the marine and transportation industries. The choice of aluminum strip depends on the specific requirements of the commercial application, such as strength, corrosion resistance, and formability.</p>

- Q: This question asks for examples of uses for aluminum siding that are not commonly thought of.

- <p>Aluminum siding is traditionally associated with residential and commercial building exteriors due to its durability and low maintenance. However, its versatility extends to less common applications such as: 1) Marine applications, where it's used for boat hulls and docks due to its resistance to corrosion from saltwater. 2) Agricultural structures, like barns and silos, for protection against weather and pests. 3) In the automotive industry for car body panels and truck beds, providing lightweight and impact-resistant surfaces. 4) For creating custom art pieces and sculptures, as aluminum can be easily shaped and finished. 5) In the manufacturing of temporary structures like disaster relief shelters, offering quick assembly and durability. These uses showcase the adaptability of aluminum siding beyond its typical applications.</p>

- Q: What is the minimum thickness that can be achieved when manufacturing an aluminum strip?

- <p>There is no absolute limit to how thin an aluminum strip can be made, but the practical limit is determined by the manufacturing process and the intended use of the strip. Modern technology allows for the production of aluminum strips as thin as a few micrometers. However, the thinness is constrained by factors such as material strength, ductility, and the specific application requirements. For instance, in the electronics industry, very thin aluminum strips are used for conductors, while in other applications, thicker strips might be necessary for structural integrity. The thinnest aluminum strips are often produced using techniques like rolling or extrusion, with the final thickness depending on the precision of these processes.</p>

Send your message to us

Decorative 1/4 Aluminum Strips Coated Coil/Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords