Aluminum Sheets for Aluminium Composite Panel Facade Decoration - Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

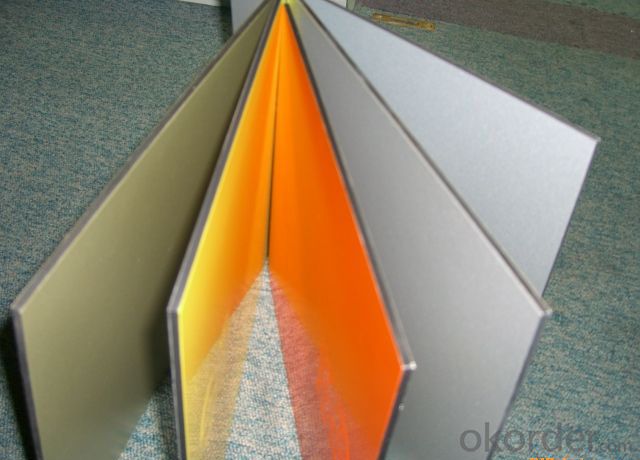

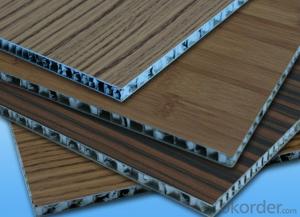

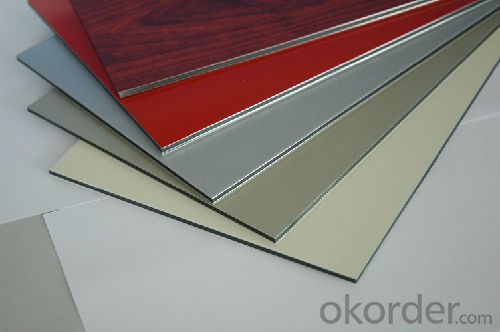

Structure of Aluminium Composite Panel Facade Decoration Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Composite Panel Facade Decoration

Extremely strong agglutination

Excellent weather resistance

Excellent fire-retardant performance

Light and easy to machining, excellent impact resistance, easy to maintain

Coating : PVDF, PE, Granite-textured, Wood-textured, Mirror

Color: at your option. ( We could mix the color according to your reqirement.)

Surface and rear aluminum foil can be coating with fresh color as your requirement.

All of Aluminum foil is made from famous aluminum manufacture

In the middle is the no-toxicity Plastic core

PVDF coating can be effected for 15 years, and the PE coating can be effected for 8 years.

Images of Aluminium Composite Panel Facade Decoration

Aluminium Composite Panel Facade Decoration Specification:

| Specification | Recommend | |

| PVDF | 4*0.4mm | Most popular in the world for out door decoration |

| 4*0.5mm | Best for out door decoration in general | |

| 4*0.3mm | Economy also meet requirement for outdoor decoration | |

| 3*0.3mm | Popular for indoor decoration in commercial building | |

| 4*0.5mm Fireproof | Superior fireproof performance on the basis of the best specification | |

| PE | 3*0.3mm | Most popular in the world for indoor decoration |

| 3*0.21mm | Economy for indoor decoration in general | |

| Standard size | 1220*2440 and 1250*2440mm | |

| Accepted width | Max:1580mm | |

| Accepted length | Max:6000mm | |

| Accepted thickness | 2mm,3mm,4mm,5mm,6mm | |

| Aluminum alloy thickness | ACP thick | AL thick |

| 2mm | 0.06mm-0.15mm | |

| 3mm | 0.06mm-0.21mm | |

| 4mm | 0.06mm-0.55mm | |

| 5mm | 0.06mm-0.55mm | |

| Weight | 5kg/m2, based on 4*0.4mm,1400pcs/20'FCL | |

| Nonstandard | Sizes are available according your requirement | |

FAQ of Aluminium Composite Panel Facade Decoration

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

A Brief Guide On Aluminum Sheets

Aluminum is the material of choice across a wide range of industries today. This metal is abundantly available, can be molded in different forms and shapes, and is more light-weight than steel. Of the different forms in which aluminum is used, sheeting is one of the most popular. In fact, you are sure to come across at least one object made of aluminum sheets every day. Whether you are in a car, traveling, or trying to open a can, or you switch on the electric bulb for a light read-chances are, all these things will contain some aluminum sheeting in them.

Sheets are formed when the aluminum block is passed between rolls under pressure. As it is rolled and re-rolled, it thins out and becomes longer in the direction in which it is moving. It becomes a sheet when the rolling process is stopped at 0.249 to 0.006 inch.

Sheets are made of different alloys so that they have the required amount of flexibility and toughness. They are graded accordingly. People then choose the variety on the use to which they will be put. Two of the most popular grades are 1100 for pure aluminum and 2011 for minor machine parts. For tougher, more durable materials, a grade of 5052 is suitable.

Many industries prefer aluminum for its wonderfully versatile and lightweight quality. The transportation industry has always loved this metal that improves fuel economy, cuts down emissions, and boosts vehicle performance. No wonder, then, that since 2006, aluminum has overtaken iron to become the second most used material in new vehicles across the world. Increasingly, car-makers are opting to become more eco-friendly by using aluminum sheets for the panels of car bodies. Other than this, bodies of planes use sheets made of this metal owing to their light-weird, robust quality.

Aluminum products are popular in households as well. A variety of objects used to build houses, such as flashing, siding, and roofs have aluminum sheets in them. Metal workers and artists also like this versatile material that can be made into furniture and art installations.

Aluminum sheets come in various qualities. The best quality is highly resistant to corrosion. Sometimes manufacturers provide customizing options depending on your need. Metalsforasteel is a great dealer that provides aluminum sheets in a variety of measurements. It also offers to discount prices for larger orders of 1000 pounds or more.

- Q: Can aluminum sheet be used for food contact applications?

- Indeed, aluminum sheet is suitable for food contact applications. The food industry extensively utilizes aluminum owing to its exceptional characteristics. It is non-toxic, resistant to corrosion, and possesses a high thermal conductivity, rendering it appropriate for an array of food processing and packaging purposes. By utilizing aluminum sheets, one can craft food containers, trays, and foils, thereby offering a secure and sanitary solution for storing and transporting food. Moreover, aluminum is recyclable, making it an environmentally conscious selection for food contact applications.

- Q: What are the different surface treatments for aluminum sheets to improve corrosion resistance?

- Aluminum sheets can be treated with several methods to greatly improve their resistance to corrosion. These treatments encompass: 1. Anodizing: Widely used, anodizing involves submerging aluminum in an electrolyte solution and applying an electric current. Consequently, a protective oxide layer forms on the surface, effectively enhancing corrosion resistance. 2. Chromate Conversion Coating: Also known as chemical film or chromating, this treatment immerses aluminum in a solution with chromate compounds. This creates a thin chromate layer serving as a barrier against corrosion. 3. Powder Coating: In this dry finishing process, a powdered polymer is sprayed onto the aluminum surface and then cured under heat. The result is a durable, corrosion-resistant coating that offers exceptional protection against environmental factors. 4. E-coating: Electrophoretic coating, or e-coating, is an immersion-based process where aluminum sheets are submerged in an electrically charged paint bath. The paint particles are attracted to the surface, creating a uniform and corrosion-resistant coating. 5. Cladding: By bonding a layer of a different metal, such as stainless steel or zinc, to the surface of aluminum sheets, cladding forms a protective barrier that shields against corrosion. 6. Organic Coatings: Applying organic coatings like acrylic or polyester paints to the aluminum surface forms an effective corrosion-resistant barrier. These coatings create a protective film that prevents moisture and corrosive substances from reaching the aluminum. It's worth noting that the choice of surface treatment depends on various factors, including the specific application, environmental conditions, and desired appearance. Consulting with professionals is advisable to determine the most appropriate treatment for a particular application, as some treatments may be better suited for certain industries or environments.

- Q: Maybe you didn't know but in the year 2025 the earth's population will be up to 12 billion people, which is double what we have now. And i am doing a project on Aluminum, and I have to know if there is enough AL for this many people in the year 2025. So will there be enough AL in the world to support us all?

- Aluminium is the third most abundant element on earth after oxygen and silicon. I am quite sure that we will not run out of aluminium in the future. Oxygen - or at least pure good quality oxygen - is probably a more worrying scenario.

- Q: How are aluminum sheets cleaned and maintained?

- Aluminum sheets can be cleaned and maintained by following a few simple steps. Firstly, they should be wiped down regularly with a soft cloth or sponge and mild detergent to remove any dirt or grime. Avoid using abrasive materials or cleaners that contain bleach or ammonia, as they can damage the surface. After cleaning, it is recommended to rinse the sheets thoroughly with clean water and dry them with a soft cloth to prevent water spots. To maintain their shine, applying a coat of aluminum polish or a mixture of vinegar and water can help remove any oxidation or dullness. Additionally, it is important to protect aluminum sheets from harsh elements by storing them in a dry and clean environment and avoiding contact with corrosive substances.

- Q: What are the physical properties of aluminum?

- Aluminum possesses a silver-white appearance and is renowned for being a lightweight and malleable metal. It exhibits a relatively low melting point of 660.3 degrees Celsius (1220.5 degrees Fahrenheit) and a boiling point of 2519 degrees Celsius (4566 degrees Fahrenheit). With a density of 2.7 grams per cubic centimeter, it is approximately one-third as dense as steel. Furthermore, aluminum serves as a proficient conductor of both electricity and heat, thus finding widespread utilization in electrical transmission lines and heat sinks. Additionally, it showcases resistance to corrosion, due to the creation of a thin oxide layer on its surface, which renders it suitable for an array of applications across industries, including construction, automotive, aerospace, and packaging.

- Q: Would a chemical reaction happen between a piece of copper and a liquid solution containing a compound of aluminum? Why or why not? FIRST BEST ANSWER GETS POINTS!

- No. Copper metal will not reduce aluminum ions to aluminum metal. We can observe that copper is below aluminum in the activity series, which indicates that the Cu + Al3+ reaction is nonspontaneous. The other way round will work, sort-of. Aluminum metal will reduce copper ions. But it takes freshly prepared aluminum metal. Aluminum metal passivates, that is, it reacts with oxygen to form an Al2O3 layer on the surface of the metal. The presence of chloride ion will help provide a clean Al surface.

- Q: How do aluminum sheets perform in terms of formability?

- Aluminum sheets are highly formable due to their low density and high malleability. They can be easily shaped into various forms and are commonly used in industries such as automotive, aerospace, and construction for their excellent formability properties.

- Q: Is it possible for an individual to install their own aluminum sheet roofing?

- <p>Yes, you can install your own aluminum sheets roof, but it requires some skills and knowledge. You'll need to measure and cut the sheets accurately, secure them properly, and ensure watertight installation. It's advisable to have experience in roofing or construction, or to follow detailed instructions and safety precautions. For complex roofs or if you're unsure, hiring a professional is recommended to avoid damage or injury.</p>

- Q: Are the aluminum sheets suitable for manufacturing automotive chassis?

- Yes, aluminum sheets are suitable for manufacturing automotive chassis. Aluminum is a lightweight and strong material, making it an ideal choice for constructing automotive chassis. It offers several advantages such as improved fuel efficiency, better handling, and increased structural rigidity. Aluminum's ability to absorb and dissipate impact energy also enhances passenger safety. Additionally, aluminum is corrosion-resistant, which helps prolong the lifespan of the chassis. Overall, using aluminum sheets in the manufacturing process of automotive chassis provides numerous benefits and is a suitable choice for this application.

- Q: What are the mechanical properties of aluminum sheets?

- Aluminum sheets are highly sought after in various industries due to their unique mechanical properties. To begin with, they possess an exceptional strength-to-weight ratio, making them both lightweight and strong. This quality is particularly valuable in industries like aerospace and automotive, where reducing weight is crucial. Furthermore, aluminum sheets are highly malleable, allowing them to be easily shaped and formed into different sizes and configurations. This versatility makes them ideal for applications that require complex shapes, such as the manufacturing of cans, appliances, and architectural components. In addition, aluminum sheets have a high resistance to corrosion, thanks to the development of a thin, protective oxide layer on their surface. This durability makes them suitable for outdoor applications or environments with high moisture or chemical exposure. Moreover, aluminum sheets exhibit excellent thermal conductivity, enabling them to efficiently transfer heat. This property makes them widely used in heat exchangers, cooling systems, and other applications where effective heat dissipation is necessary. Lastly, aluminum sheets possess good electrical conductivity, allowing them to effectively conduct electricity. This makes them suitable for electrical enclosures, conductors, and other electrical applications. To summarize, the mechanical properties of aluminum sheets include a high strength-to-weight ratio, good formability, high corrosion resistance, excellent thermal conductivity, and good electrical conductivity. These properties make aluminum sheets the preferred choice for a wide range of applications across various industries.

Send your message to us

Aluminum Sheets for Aluminium Composite Panel Facade Decoration - Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords