304 Cold Rolled Stainless Steel for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

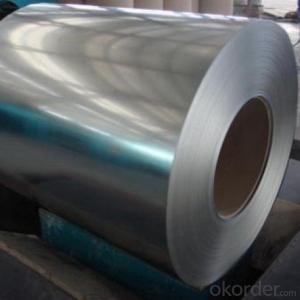

Model NO.:304/304L/316/316L/321/409/409L/410/410S/430

Type:Stainless Steel Strips

Shape:Coil

Grade:300 Series

Certification:ISO, SGS

Perforated:Not Perforated

Standard:ASTM, AISI, GB, JIS, DIN, EN

Technique:Cold Rolled

Surface Treatment:Bright

Surface:2D,2e,2b,2bb,Sb,No.4,Ba,Hl,6k,7k,8k

Width:1000mm/1219mm/1250mm/1500mm/1524mm/1829mm/2000mm

Thinckness:0.3mm to 6mm

Edge:Silt/Mill Edge

Export Markets:Global

Product Description

The detail specification of cold rolled stainless steel coils are as below:

| Grade: | 201/202/301/304/304L/316/316L/317L/321/409/409L/410/410S/430/439 |

| Standard: | ASTM,AISI,JIS,EN,DIN,GB |

| Surface: | 2D,2E,2B,2BB,SB,NO.4,BA,HL,6K,7K,8K |

| Width: | 1000mm/1219mm/1250mm/1500mm/1524mm/1829mm/2000mm |

| Thickness: | 0.3mm to 6mm |

| Edge: | Slit/Mill Edge |

| Origin: | TISCO,POSCO,LISCO,JISCO,BAOSTEEL,Baoxin,Eastern Special Steel and so on |

| Productivity: | 10000MT/Mont |

| MOQ: | 30mont |

| Payment Term: | TT,L/C at sight/, L/C 30,60,90,180 days,WEST UNION |

| Price Term: | FOB/CFR/CIF Ningbo,Shanghai,Tianjin,Shenzhen Port |

| Delivery: | 7-10 days after receive buyer's advance deposit or LC copy |

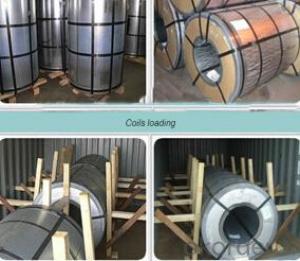

| Packaging: | Seaworthy Export Standard Package.Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might otherwise be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information. |

| Detail Application: | construction field;ship building industry;petroleum and chemical industries;war and electricity industries;food processing and medical industry; boiler heat exchanger; machinery and hardware industry |

Technical notes:

| Surface Finish | Definition | Application |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2D | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment. | Construction Material, heat exchanger,exhaust pipe |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| No.8 | A highly reflective finish obtained by polishing with successively finer abrasive and buffing extensively free of grit lines | Indoor decoration & Reflector, Hospital Equipment |

Our Advantages

All products are made of high-quality imported raw materials.

Excellent shipment after-sales service & Prompt

The Authorized agent of TISCO,JIISCO,the stainless steel distributor of BOSTEEL,ZPSS,LISCO and also can get the resources from all the stainless steel mills in China.

Have own processing and distribution center & can take the orders according to customers' requirements.

The transport in Hangzhou is very convenient & nearby Shanghai and Ningbo Port.

Our products are certified by ISO9001:2008 authentication quality systems.

Quick Response to Your Enquiry.

- Q: Hi,Well, I live near almost across the street from a forest, and my neighborhood is full of raccoons!!! Recently, I just purchased a bunny and have kept it at my cousin's house for the time being. He has a steel cage, and is about 6 months old. I am considering bringing him home and leaving him in the back yard with his steel cage. I am just afraid that raccoons can bite through the steel and get to him. So the question is... Is is possible for raccoons to bite through steel? Btw,Please don't answer hate comments about me being a bad rabbit owner. I simply want to know if raccoons can bite through steel. If it doesn't work out, the rabbit will stay at my cousins house until further notice. But please, I did not waste 5 points for unneeded answers. Thanksss!

- Well the raccoons can't bite through steel unless it is very thin steel, like aluminum foil thickness. But they have long arms and can reach into the cage so that would be my worry. They are also very clever so I don't know if it is safe for the bunny. That would depend upon the size of the cage and how hungry the raccoons are. The raccoons might be tempted to try to steal the bunny's food so that is a concern. Check with a pet shop owner or forester or someone like that who has knowledge about raccoons in the area.

- Q: I thought it was STAINLESS STEEL! I have stainless steel can openers spatulas that are rusty. What's up with that? did you know that braces on people's teeth are made of stainless steel? That's why they call people metal-mouth. I used to have braces.

- Stainless steel is manufactured in a variety of different alloys. The percent of Chrome and other metals determine which alloy of stainless is produced. Not all versions of stainless is rust proof, just rust resistant. Not knowing which version of stainless steel you are discussing makes an exact answer difficult. Most stainless steel needs also be exposed to oxygen to retain it's 'stainless' properties. There are also version of steel, Monel and Inconel, that most would consider 'stainless'. Salt water will rapidly affect most versions of stainless with what is called cloride stress corrosion which cause a failure of the lattice structure of the metal. Generally, some stainless steel with a lower chrome content may appear to have discoloration that appears to be rust.

- Q: How can defects in steel coils be detected?

- Defects in steel coils can be detected through various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. These techniques help identify surface cracks, internal flaws, irregularities in thickness, and other defects, ensuring the quality and integrity of the steel coils.

- Q: I installed it, added it in F3 launcher and then after one minute of walking in wasteland I get a signal that Broken steel was added and that my level of caps was raised by 30. However after this message no quest is added. I played all 4 exp. packs and I had no problem at all, each time a new quest was added. So whats up with this Broken steel. Btw, I completed the entire game F3.

- Yeah you awaken after the ending cutscene in case you have it put in and then yet another quest line is given to you and you will circulate on your merry way doing in spite of you experience like.

- Q: How are steel coils used in the automotive industry?

- Steel coils are widely used in the automotive industry for various applications such as body panels, structural components, and engine parts. They are typically formed and shaped into desired forms through processes like stamping, bending, and welding. Steel coils provide strength, durability, and corrosion resistance to the vehicles, ensuring their safety and longevity.

- Q: Can steel coils be used in the production of electrical components?

- Indeed, the utilization of steel coils is possible in the manufacturing of electrical components. It is common practice to employ steel coils as magnetic cores in transformers and inductors. The magnetic properties inherent in steel render it an optimal substance for bolstering the efficacy and effectiveness of electrical components. Wrapping the coils around the steel core serves to concentrate and direct the magnetic field, guaranteeing a seamless and efficient operation. Additionally, steel coils find application in the creation of solenoids, motors, generators, and other electrical contrivances wherein magnetic fields are indispensable for proper functioning. On the whole, steel coils assume a pivotal role in the production of diverse electrical components, thereby contributing to their trustworthy and high-performance operation.

- Q: What are the different methods of surface cleaning for steel coils?

- There are several different methods available for surface cleaning of steel coils. The choice of method depends on the specific requirements and conditions. 1. Mechanical Cleaning: This method involves the use of mechanical tools such as wire brushes, sanding discs, or abrasive pads to physically remove dirt, rust, or other contaminants from the surface of the steel coils. It is commonly used for light cleaning and can be done manually or with the help of automated equipment. 2. Chemical Cleaning: Chemical cleaning involves the use of various cleaning agents or solvents to dissolve or loosen contaminants from the surface of steel coils. This method is effective for removing oil, grease, or stubborn dirt. Different chemicals can be used depending on the type of contaminants and the desired level of cleaning. It is important to follow safety guidelines and use appropriate protective equipment when using chemical cleaners. 3. Power Washing: Power washing or pressure washing utilizes a high-pressure water jet to remove loose particles, dirt, or contaminants from the surface of steel coils. This method is effective for large-scale cleaning and can be combined with chemical cleaners for enhanced results. It is important to adjust the water pressure according to the type of surface and use appropriate nozzles to prevent damage. 4. Pickling: Pickling is a chemical cleaning method that involves the immersion of steel coils in an acidic solution, typically a mixture of hydrochloric acid and sulfuric acid. This process removes scale, oxides, and other impurities from the surface of the steel. Pickling is commonly used for heavy-duty cleaning and preparation of steel coils before further processing or coating. 5. Electrolytic Cleaning: Electrolytic cleaning utilizes an electric current to remove contaminants from the surface of steel coils. The coils are immersed in an electrolyte solution, and the application of a direct current causes the contaminants to dissolve or dislodge from the surface. This method is particularly effective for removing rust or corrosion and can be used in conjunction with other cleaning methods. It is important to consider factors such as the type and condition of the steel coils, the level of cleanliness required, and any specific industry standards or regulations when choosing the appropriate method of surface cleaning. Regular maintenance and cleaning of steel coils are essential to ensure their longevity, performance, and resistance to corrosion.

- Q: What are the common methods of inspecting steel coils for quality control?

- There are several common methods of inspecting steel coils for quality control purposes. These methods typically involve visual inspection, dimensional measurement, and non-destructive testing. Visual inspection is one of the simplest and most common methods used to inspect steel coils. It involves visually examining the surface of the coils for any visible defects, such as scratches, dents, or discoloration. Visual inspection can also include checking for proper labeling, packaging, and any signs of corrosion or damage. Dimensional measurement is another important method used to ensure the quality of steel coils. This involves measuring various dimensions of the coils, such as thickness, width, and length, to ensure they meet the required specifications. Dimensional measurement can be performed using various tools such as calipers, micrometers, or laser measurement devices. Non-destructive testing (NDT) techniques are also commonly employed to inspect steel coils. NDT methods allow for the detection of internal and surface defects without damaging the material. One common NDT technique used for steel coil inspection is ultrasonic testing, which involves sending high-frequency sound waves through the coil and analyzing the reflected waves to identify any defects. Magnetic particle testing and dye penetrant testing are also used to detect surface cracks or defects in the coils. In addition to these methods, other quality control practices may include chemical analysis to ensure the composition of the steel meets the required standards, mechanical testing to evaluate the strength and hardness of the material, and corrosion testing to assess the resistance of the coils to corrosion. Overall, a combination of visual inspection, dimensional measurement, and non-destructive testing techniques is typically employed to ensure the quality and integrity of steel coils during the quality control process.

- Q: What are the applications of steel coils in automotive manufacturing?

- Steel coils have various applications in automotive manufacturing. They are used primarily for the production of car bodies, as well as for other components such as doors, hoods, fenders, and trunk lids. Steel coils provide high strength, durability, and formability, making them suitable for creating robust and safe vehicles. Additionally, they offer excellent resistance to corrosion and can be easily molded into complex shapes, ensuring the desired design aesthetics and functionality.

- Q: Well actually I was just wondering why people were bashing on stainless so much for katanas. I heard that they don't hold their edge as well as carbon steel blades or Damascus steel. So what makes it so inferior to carbon or other types of steels?

- There are many kinds of stainless steel. 440c, 420j, ATS34, and so on. Cold steel uses 420 type steels in several of their products. High carbon stainless steels cut well but edge retention is not very good but that also depends on the heat treating of the metal. I could go on all day but very, very basically stainless steels lack the shatter resistance necessary when stretched to great lengths. This is in part why other steels make far better swords. The stuff sold on QVC is just plain junk. Do not buy a stainless steel sword. A blade made of 440S means it belongs hung on a wall...

Send your message to us

304 Cold Rolled Stainless Steel for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords