1/4 Sheets Aluminum - High Quality Aluminium Coil PVDF Coating Painted

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

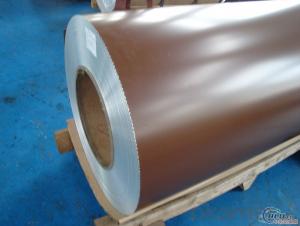

Structure of Aluminium Coil PVDF Coating Painted Hight Quality Description:

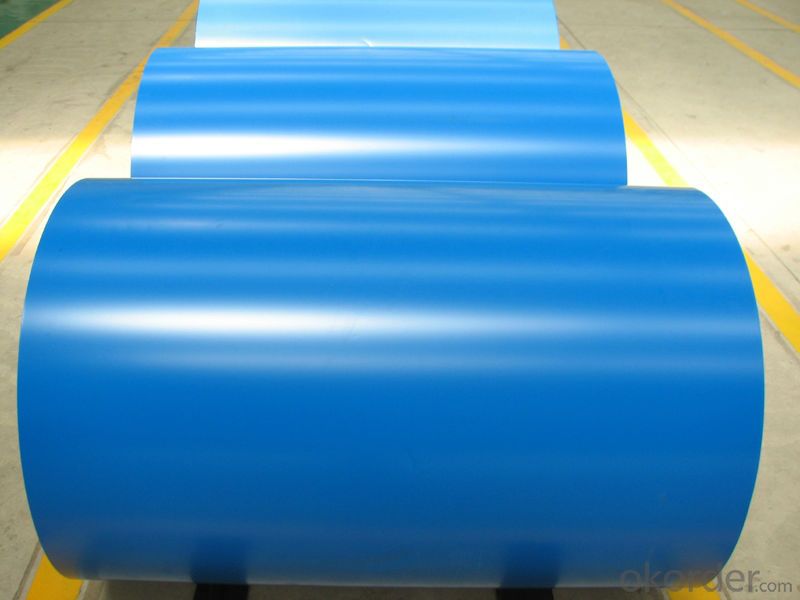

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

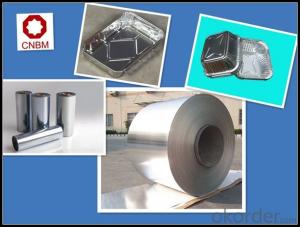

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coil PVDF Coating Painted Hight Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Coil PVDF Coating Painted Hight Quality:

Aluminium Coil PVDF Coating Painted Hight Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Coil PVDF Coating Painted Hight Quality:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with saltwater?

- To prevent galvanic corrosion when using aluminum sheets with saltwater, several measures can be taken. Firstly, applying a protective coating or paint to the aluminum surface creates a barrier between the metal and the saltwater, reducing the chances of corrosion. Secondly, using sacrificial anodes made of a more reactive metal, such as zinc, can divert the electrolytic current away from the aluminum sheets, preventing corrosion. Additionally, ensuring proper insulation and avoiding contact with dissimilar metals can also help minimize the risk of galvanic corrosion in saltwater environments.

- Q: could aluminum sheet be attracted by magnet?

- no, it couldn't.

- Q: Can the aluminum sheets be used for insulation purposes?

- Aluminum sheets have the ability to serve as insulation material. Due to its high thermal conductivity, aluminum can effectively hinder the transmission of heat between two surfaces. For instance, aluminum sheets can be utilized as a reflective shield within walls, roofs, or floors to minimize heat transfer by reflecting radiant heat. They can also act as a vapor barrier, preventing the ingress or escape of moisture in a given space. Furthermore, aluminum sheets can be incorporated into an insulation system, combining them with other insulating materials like foam or fiberglass to augment their thermal insulation properties. In conclusion, aluminum sheets deliver efficient insulation and contribute to energy efficiency in buildings.

- Q: Are aluminum sheets suitable for elevator interiors?

- Yes, aluminum sheets are suitable for elevator interiors. Aluminum is a durable and lightweight material that is resistant to corrosion, making it ideal for use in elevator interiors. It can be easily customized and offers a sleek and modern aesthetic. Additionally, aluminum is easy to clean and maintain, making it a practical choice for elevator interiors.

- Q: how to find 0.6mm waste strake of aluminum sheet?

- ask door and window maker for some strake.

- Q: Could two pieces of aluminum sheets be welded together?

- youcan use aluminium soldering,what do you want to weld?

- Q: why does 10% sulfuric acid not react with aluminum sheet?

- 10% sulfuric acid has a high concentration and will be passivated and formulate a layer of oxide film after reacting with aluminum,and the reaction will stop after seperating sulfuric acid and aluminum. there is a layer of Al2O3 oxide film on the surface of aluminum, so it's hard for sulfuric acid to break the oxide film and react with aluminum.

- Q: Can 101 aluminum sheets be used in the production of sporting goods?

- Indeed, 101 aluminum sheets possess the potential to serve as a valuable resource in the creation of sporting goods. The versatility of aluminum as a material grants numerous advantages to sporting equipment. Notably, its lightweight nature becomes paramount when it comes to various sports gear such as bicycles, tennis rackets, and baseball bats. This attribute facilitates effortless handling and enhances maneuverability. Furthermore, aluminum boasts corrosion resistance, ensuring the durability of sporting goods even when exposed to diverse weather conditions. Moreover, its exceptional strength-to-weight ratio renders it suitable for high-performance equipment, enabling durability without unnecessary bulk. Consequently, the utilization of 101 aluminum sheets emerges as a viable option for manufacturing a wide range of sporting goods, effectively delivering the desired properties essential for optimum performance, longevity, and user satisfaction.

- Q: Can aluminum sheets be used for structural purposes?

- Yes, aluminum sheets can be used for structural purposes. Aluminum is a lightweight and highly malleable material that can be easily fabricated into various shapes and sizes. It has excellent strength-to-weight ratio, making it suitable for structural applications where weight reduction is a priority. Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction for making structural components like panels, beams, and frames. Additionally, aluminum has good corrosion resistance, which further enhances its suitability for structural purposes, especially in outdoor or marine environments. Overall, aluminum sheets offer a reliable and cost-effective solution for structural applications.

- Q: Are aluminum sheets suitable for aircraft panels?

- Indeed, aircraft panels can be made from aluminum sheets. The aviation industry extensively employs aluminum due to its exceptional strength-to-weight ratio, rendering it an ideal choice for constructing aircraft structures that are both lightweight and robust. Aluminum sheets are frequently utilized for aircraft panels owing to their durability, resistance to corrosion, and ease of fabrication. Moreover, aluminum can be effortlessly molded and welded, enabling the creation of intricate panel shapes. Furthermore, aluminum possesses commendable electrical conductivity, a crucial factor in the efficient operation of diverse aircraft systems. In summary, the utilization of aluminum sheets for aircraft panels plays a pivotal role in ensuring the aircraft's structural integrity and performance.

Send your message to us

1/4 Sheets Aluminum - High Quality Aluminium Coil PVDF Coating Painted

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords