Aluminum Perforated Metal Sheets with Mill Finished Surface AA3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets with Mill Finished Surface AA3XXX

Aluminum Sheets with Mill Finished Surface AA3XXX are strengthened and cut from raw materials with different alloys, such as AA3003, AA3105, etc.

Aluminum Sheets with Mill Finished Surface AA3XXX are light, easy for processing in different shapes, good in intensity and can be quickly installed.

Aluminum Sheets with Mill Finished Surface AA3XXX are widely used in curtain walls, roofing, decoration, boats, airframes, instrument panels, etc.

2.Main Features of Aluminum Sheets with Mill Finished Surface AA3XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

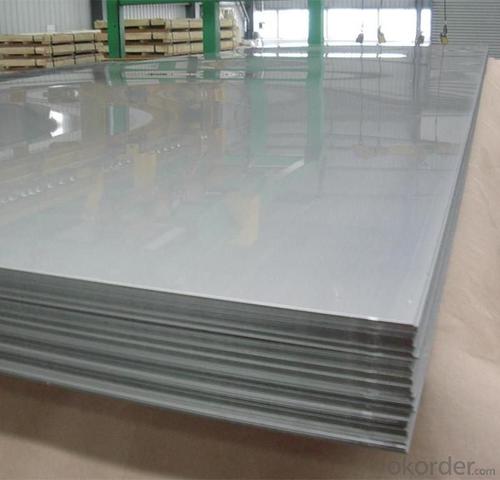

3.Aluminum Sheets with Mill Finished Surface AA3XXX Images

4.Specification of Aluminum Sheets with Mill Finished Surface AA3XXX

Alloy Number | AA3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Aluminum Sheets with Mill Finished Surface AA3XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA3XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA3XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: This question asks for an identification of various types of aluminum sheets that are typically utilized in construction projects.

- <p>Aluminum sheets used in construction come in various types, each with specific properties and applications. Common types include: 1) Mill Finish Sheets: These have a natural aluminum finish and are used for applications requiring a raw aluminum look. 2) Painted Aluminum Sheets: Coated with paint for enhanced durability and color options, suitable for exterior applications. 3) Anodized Aluminum Sheets: Durable and corrosion-resistant, often used for architectural features. 4) Embossed Aluminum Sheets: Offered with various textures for design purposes. 5) Perforated Aluminum Sheets: Used for decorative or functional purposes, such as ventilation. 6) Aluminum Composite Material (ACM) Sheets: Consisting of two aluminum sheets with a non-aluminum core, used for cladding. Each type is chosen based on the project's specific requirements for aesthetics, strength, and environmental resistance.</p>

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Yes, aluminum sheets are suitable for use in food processing and packaging industries. Aluminum is a versatile and widely used material in the food industry due to its excellent properties and advantages. Firstly, aluminum is a non-toxic material, making it safe for direct contact with food. It does not react with food or alter its taste, ensuring the preservation of the original flavor and quality. This is particularly important in the packaging industry, as it helps to maintain the freshness and integrity of the food product. Secondly, aluminum has excellent thermal conductivity, which allows for efficient and even heat distribution during food processing. This property is beneficial for cooking, baking, and other thermal processes, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets offer excellent barrier properties, such as resistance to moisture, light, and gases. This helps to protect food from external factors that could potentially deteriorate its quality, such as moisture or oxygen. It also helps to prolong the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet strong and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and protects the food during transportation and storage. Lastly, aluminum is a sustainable material. It is 100% recyclable, meaning that it can be reused without losing its properties. This helps to reduce the environmental impact and supports the circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q: How do you ensure the dimensional accuracy of aluminum sheets?

- To ensure the dimensional accuracy of aluminum sheets, several steps can be taken: 1. Precise Manufacturing Process: The aluminum sheets should be manufactured using advanced equipment and techniques that guarantee accurate dimensions. This involves using reliable and calibrated machinery to ensure the sheets are cut, rolled, and formed precisely to the desired specifications. 2. Quality Control Measures: Implementing a comprehensive quality control system is crucial in maintaining dimensional accuracy. This involves regular inspections and measurements at various stages of the manufacturing process to identify any deviations from the required dimensions. This can be done using precision measuring instruments such as calipers, micrometers, or laser scanning devices. 3. Material Selection: The quality of the aluminum used in sheet production plays a significant role in dimensional accuracy. Using high-quality aluminum with consistent properties and minimal impurities ensures that the sheets maintain their desired dimensions throughout the manufacturing process. 4. Temperature Control: Aluminum sheets can be sensitive to temperature variations, which can cause expansion or contraction and affect dimensional accuracy. Maintaining a controlled temperature environment during manufacturing helps minimize these effects and ensures the sheets retain their intended dimensions. 5. Proper Handling and Storage: Aluminum sheets should be handled and stored with care to prevent any deformation or damage that could impact their dimensions. This includes using appropriate lifting equipment, avoiding excessive bending or twisting, and storing them in a controlled environment to prevent exposure to moisture or extreme temperatures. 6. Regular Calibration: It is essential to regularly calibrate the measuring instruments used in the dimensional inspection process. This ensures accurate measurements and eliminates any potential errors that may arise from instrument drift or wear. By following these steps, manufacturers can minimize dimensional variations and maintain the desired accuracy of aluminum sheets, meeting the specific requirements of various applications in industries such as automotive, aerospace, construction, and electronics.

- Q: Is it possible to use aluminum sheets as a material for exterior walls in regions with cold climates?

- <p>Yes, aluminum sheets can be used for exterior walls in cold climates. Aluminum is a durable and lightweight material with good thermal conductivity, which can be beneficial for heat transfer. However, it's crucial to use insulated aluminum panels or combine aluminum with insulation materials to prevent heat loss and maintain indoor comfort. Proper design and installation are essential to ensure the building envelope's thermal performance and structural integrity in cold weather conditions.</p>

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with other metals?

- One effective way to prevent galvanic corrosion when using aluminum sheets with other metals is by using a protective barrier, such as a coating or a layer of paint, on the aluminum surface. This barrier acts as a physical barrier between the aluminum and the other metal, preventing direct contact and minimizing the galvanic corrosion. Additionally, using compatible metals and alloys, as well as proper insulation and isolation techniques, can further reduce the risk of galvanic corrosion in such applications.

- Q: The question asks if it is possible to recycle used aluminum foil to create new aluminum sheets.

- <p>Yes, recycled aluminum foil can be used to make new aluminum sheets. The process involves collecting and sorting the foil, which is then cleaned and melted down. The molten aluminum is poured into molds or rolled into sheets, creating new aluminum products. This recycling method is not only environmentally friendly but also economically viable as it saves energy compared to producing aluminum from raw materials.</p>

- Q: How do I cut aluminum sheets?

- To cut aluminum sheets, you will need a few tools and precautions. Here's a step-by-step guide to help you through the process: 1. Safety first: Always wear protective gear, including safety glasses, gloves, and a dust mask to protect yourself from the metal shavings. 2. Choose the right tool: There are a few options for cutting aluminum sheets, depending on their thickness. For thin sheets (up to 1/8 inch), a manual hand shear or a utility knife with a sharp blade can be sufficient. For thicker sheets, you may need power tools such as a jigsaw, circular saw, or a specialized aluminum-cutting saw. 3. Measure and mark: Use a measuring tape, ruler, or a straightedge to determine the desired size of the sheet. Mark the cutting line on the sheet using a permanent marker or a scribe. 4. Secure the sheet: Use clamps to secure the aluminum sheet firmly to a workbench or a cutting surface. This will prevent the sheet from moving during the cutting process, ensuring accurate cuts. 5. Cutting with a hand shear or utility knife: For thin sheets, start by aligning the cutting edge of the shear or utility knife with the marked line. Apply firm and even pressure to make a straight cut. If using a utility knife, you may need to score the sheet several times before it breaks off. 6. Cutting with power tools: If using a jigsaw, circular saw, or an aluminum-cutting saw, make sure you have the appropriate blade for cutting metal. Set the saw's cutting depth slightly deeper than the thickness of the aluminum sheet. Align the blade with the marked line and slowly guide the saw along the cutting path, ensuring a smooth and steady motion. Apply light pressure and let the saw do the work. 7. Finishing touches: Once the cut is complete, inspect the edge for any burrs or roughness. Use a metal file or sandpaper to smooth out any imperfections. Remember, practice caution and take your time when cutting aluminum sheets. It's always a good idea to test your cutting method on a small scrap piece before proceeding with the actual sheet.

- Q: Are aluminum sheets suitable for automotive heat shields?

- Certainly! Automotive heat shields can indeed utilize aluminum sheets. Aluminum is an exceptional option for heat management in automotive applications due to its lightweight nature and impressive conductivity. Its high melting point and excellent thermal conductivity properties allow it to efficiently absorb and disperse heat produced by the vehicle's engine, exhaust system, and other heat sources. Furthermore, aluminum sheets are easily moldable and can be crafted into diverse sizes and designs, making them adaptable for various automotive heat shield purposes. In summary, aluminum sheets offer an economical and effective means of safeguarding vulnerable components from heat-related harm within automotive systems.

- Q: What is the maximum size available for aluminum sheets?

- The maximum size of aluminum sheets can differ based on the manufacturer and specific demands. Nonetheless, aluminum sheets can typically be found in sizes of up to 4 feet by 12 feet (48 inches by 144 inches) or even larger. Industries such as construction, aerospace, and automotive manufacturing often utilize these bigger dimensions. It's worth mentioning that custom sizes can also be created to meet individual project requirements.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Perforated Metal Sheets with Mill Finished Surface AA3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords