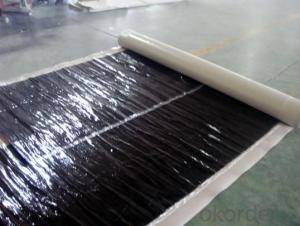

Self Adhesive Polymer Bitumen Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Wide self-adhesive pre PU polyester tyre water-proof coiled material (hereinafter referred to as pre Pu py) is to pitch based polyester tyre water-proof coiled material as the main material (add functional additives), both sides are coated with a self-adhesive layer and attached strippable coating silicon film as insulating material made of self-adhesive water-proof coiled material.

Wide self-adhesive macromolecular pre Pu waterproofing materials (hereinafter referred to as pre shop class P) with ethylene vinyl acetate (EVA), high density polyethylene (HDPE) homogeneous sheet material as the main body, covered with the self-adhesive layer, then covered with a silicon coated isolation membrane made of high polymer self-adhesive waterproofing membrane. According to the engineering needs, it can be in the polymer layer on the composite soil fabric, strengthen the strength of the membrane.

Wide wet PU polyester tyre water-proof coiled material is to pitch based polyester tyre water-proof coiled material as the main material (add functional additives), single or double coated adhesive layer and attached peelable coated silicon membrane as barrier materials made of wet laid waterproofing membrane.

Specification

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Advantages

Excellent waterproofness;

Unique creep properties and self-healing capability which can recover by itself;

Strong adhesion which can targeted the leakage in localized areas;

Tight joints, good extensibility;

Good stability and corrosion resistance, lasting effect.

FAQ

1. Is sample available before place orders?

A: Yes, sample is ok.

2. How long is the dispatch period?

A: It will be around 20-30 days.

- Q: Can a waterproofing membrane be used on EPDM roofs?

- Yes, a waterproofing membrane can be used on EPDM roofs. EPDM (ethylene propylene diene terpolymer) is a highly durable and flexible synthetic rubber roofing material commonly used for low-slope and flat roofs. While EPDM roofs are already waterproof, applying an additional waterproofing membrane can provide an extra layer of protection and enhance the roof's longevity. The waterproofing membrane can act as a barrier against water infiltration, preventing leaks and moisture damage. However, it is important to ensure that the waterproofing membrane is compatible with EPDM and follows the manufacturer's guidelines for installation to maintain the roof's integrity.

- Q: Are waterproofing membranes resistant to oil and grease?

- Waterproofing membranes are commonly resistant to oil and grease. They are specifically designed to prevent water infiltration and can also withstand exposure to chemicals like oil and grease. This resistance is achieved by using specialized materials and coatings that can repel or prevent absorption of oil and grease. However, it is crucial to mention that the level of resistance may differ based on the type and brand of the waterproofing membrane. Thus, it is recommended to refer to the manufacturer's specifications or seek professional advice to ensure the chosen membrane is suitable for the specific application and level of oil and grease exposure.

- Q: Can waterproofing membranes be used on elevator shafts?

- Yes, waterproofing membranes can be used on elevator shafts. Elevator shafts are often subject to moisture, especially in areas with high humidity or underground installations. Waterproofing membranes are designed to provide a protective barrier against water and moisture, preventing them from seeping into the elevator shaft and causing damage to the structural components or electrical systems. These membranes are typically applied to the walls and floors of the shaft, creating a watertight seal that keeps the interior dry. Additionally, waterproofing membranes can also help to prevent the growth of mold and mildew, ensuring a safe and healthy environment for elevator passengers and maintenance personnel.

- Q: Can a waterproofing membrane be used in bathrooms or showers?

- Yes, a waterproofing membrane can be used in bathrooms or showers. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and leakage. A waterproofing membrane acts as a barrier that prevents water from penetrating through the walls, floors, and other surfaces in the bathroom or shower. It is typically applied before tiling or finishing the surfaces, providing an extra layer of protection against moisture and ensuring that the underlying structure remains dry. This not only helps to prevent mold and mildew growth but also prolongs the lifespan of the bathroom or shower.

- Q: Can a waterproofing membrane be installed in cold weather?

- Yes, a waterproofing membrane can be installed in cold weather. However, it is important to consider the manufacturer's guidelines and product specifications as extreme cold temperatures can affect the adhesion and curing process of the membrane. Additionally, proper surface preparation and appropriate installation methods are crucial in ensuring the membrane's effectiveness in cold weather conditions.

- Q: Can waterproofing membranes be used on stormwater management systems?

- Indeed, stormwater management systems can benefit from the application of waterproofing membranes. These membranes are frequently utilized to safeguard structures against water infiltration and potential water-related harm. In the case of stormwater management systems, which are designed to collect, retain, and efficiently handle rainwater runoff, waterproofing membranes can be employed to establish a completely watertight seal, thereby averting leaks and seepage. Stormwater management systems often incorporate various components, such as retention ponds, infiltration basins, or underground storage systems. These elements must be adequately sealed to ensure the proper containment and effective management of the collected stormwater. When properly installed, waterproofing membranes serve as an impermeable barrier, effectively preventing water from escaping or infiltrating the system. The utilization of waterproofing membranes on stormwater management systems offers numerous advantages. Firstly, it helps to maintain the system's integrity and functionality by preventing leaks or seepage that could compromise its performance. This ensures that the stormwater is efficiently captured and managed, minimizing the risk of flooding or erosion. Furthermore, waterproofing membranes can significantly prolong the lifespan of stormwater management systems by safeguarding them against water damage. Water infiltration can lead to structural degradation, corrosion, or the proliferation of mold and mildew, all of which weaken the system over time. By establishing a waterproof barrier, these membranes contribute to the preservation of the structural integrity of the components, thus increasing their longevity and reducing maintenance requirements. Moreover, the use of waterproofing membranes on stormwater management systems also contributes to environmental sustainability. By effectively containing and managing stormwater runoff, these systems aid in reducing water pollution and enhancing the quality of natural water bodies. Waterproofing membranes play a vital role in preventing stormwater from carrying pollutants, such as chemicals or sediment, into rivers, lakes, or oceans. In conclusion, waterproofing membranes can be effectively utilized on stormwater management systems to establish a watertight seal, prevent leaks, and protect the components from water damage. By providing an impermeable barrier, these membranes help to maintain the system's functionality and integrity, prolong its lifespan, and contribute to environmental sustainability by reducing water pollution.

- Q: Can a waterproofing membrane be used on below-grade walls?

- Yes, a waterproofing membrane can be used on below-grade walls to prevent water infiltration and moisture damage.

- Q: Can a waterproofing membrane be used on swimming pool decks?

- Yes, a waterproofing membrane can be used on swimming pool decks. Waterproofing membranes are designed to create a barrier against water penetration, making them ideal for protecting areas exposed to moisture, such as swimming pool decks. These membranes are typically applied to the surface of the deck, forming a seamless and durable waterproof layer. This helps prevent water from seeping into the deck, avoiding potential damage caused by moisture, such as cracking, mold growth, or structural deterioration. Additionally, waterproofing membranes can also provide added benefits, such as increasing the lifespan of the deck and improving its overall appearance.

- Q: Can waterproofing membranes be used in basements?

- Basements can indeed benefit from the use of waterproofing membranes. These specialized membranes are designed specifically to act as a barrier against water penetration and are commonly employed in basements to effectively prevent moisture and water seepage. Typically composed of materials like rubber, bitumen, or polyethylene, these membranes are carefully applied to the walls and floors of the basement, creating an impermeable seal that keeps water out. By effectively stopping water from entering the basement, these membranes play a crucial role in safeguarding the foundation, walls, and interior spaces from the damaging effects of water, including mold and other moisture-related problems. Moreover, for comprehensive protection against water infiltration, waterproofing membranes can be utilized in conjunction with other waterproofing techniques like drainage systems and sump pumps.

- Q: Can a waterproofing membrane be used for a fountain waterproofing system?

- Yes, a waterproofing membrane can be used for a fountain waterproofing system. A waterproofing membrane is a barrier that is designed to prevent water from infiltrating or leaking through the structure it is applied to. This membrane is typically made of materials such as rubber, PVC, or bitumen, and is applied to surfaces such as concrete, stone, or masonry. In the case of a fountain waterproofing system, a waterproofing membrane can be applied to the interior surfaces of the fountain to prevent water from seeping through and causing damage. The membrane acts as a protective layer that ensures the water remains contained within the fountain, preventing leaks or seepage. It is important to select a waterproofing membrane that is specifically designed for fountains or water features. This type of membrane should be able to withstand constant exposure to water, as well as the specific conditions and chemicals that may be present in a fountain environment. Additionally, proper installation and maintenance are crucial to ensure the effectiveness of the waterproofing membrane. It is recommended to consult with a professional waterproofing contractor or fountain specialist to assess the specific requirements of your fountain and to determine the most suitable membrane and installation method. Overall, a waterproofing membrane can be an effective solution for ensuring the waterproofing of a fountain system, helping to maintain its structural integrity and prevent water-related damage.

Send your message to us

Self Adhesive Polymer Bitumen Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords