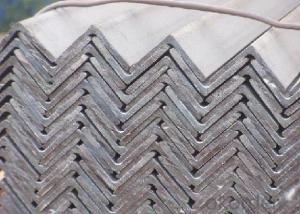

S235JR Angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering S235JR Angle, angle steel, galvanized angle steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

S235JR Angle, angle steel, galvanized angle steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's S235JR Angle, angle steel, galvanized angle steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description:

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse.

Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two.

Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 312.5px for large angle steel, 312.5px - 125px for the medium angle, length of 125px for smallangle.

Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series.

Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m.

Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125

Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How do steel angles contribute to the overall stiffness of a structure?

- The overall stiffness of a structure is enhanced by steel angles in various ways. Firstly, they offer additional support and rigidity to the framework. Their L-shape allows them to reinforce the corners and edges of different components like beams, columns, and trusses, preventing buckling, twisting, or bending under heavy loads or external forces. Furthermore, steel angles can be strategically positioned in crucial areas of the structure to efficiently resist and distribute loads. By incorporating steel angles as bracing elements, the structure's overall stiffness improves, reducing the risk of excessive deflection or deformation. This is especially vital for structures exposed to dynamic loads, such as wind or seismic forces, as the angles effectively resist and dissipate these forces throughout the structure. Moreover, steel angles can be interconnected to create a network of diagonal bracing, greatly enhancing the structure's stiffness and stability. This bracing system allows the angles to transfer loads from one component to another, effectively minimizing the possibility of failure or collapse. Additionally, using steel angles in this manner reduces the required material and weight, making the structure more cost-effective and efficient. To summarize, steel angles play a pivotal role in contributing to a structure's overall stiffness by providing reinforcement, supporting key components, and distributing loads. Their strength and versatility make them an essential element in designing and constructing various types of structures, guaranteeing stability, durability, and safety.

- Q: How do steel angles perform under vibration or resonance conditions?

- Steel angles are widely recognized for their exceptional structural properties, specifically their ability to endure vibrations and resonance circumstances. In the presence of vibrations, steel angles demonstrate impressive stiffness and damping characteristics, allowing them to proficiently dissipate the energy generated by these vibrations. This behavior is a result of the inherent material properties of steel, including its substantial strength and rigidity. Additionally, steel angles exhibit commendable performance under resonance conditions. Resonance arises when the frequency of external excitation matches the natural frequency of the steel angle. In such instances, the steel angle may encounter amplified vibrations that could potentially lead to structural failure if not adequately addressed. Nevertheless, steel angles are meticulously designed and fabricated with resonance considerations in mind, guaranteeing their capacity to withstand and alleviate the repercussions of resonance. To further enhance the performance of steel angles under vibration or resonance conditions, engineers can employ an array of techniques. These techniques encompass the incorporation of damping materials or devices to absorb or dissipate vibrational energy, the alteration of the geometric properties of the steel angle to modify its natural frequency, and the utilization of vibration isolation systems to minimize the transmission of vibrations to the steel angle. In conclusion, steel angles are exceptionally suitable for applications that require resistance to vibrations or resonance conditions. Their remarkable strength, stiffness, and damping properties enable them to effectively withstand and mitigate the effects of vibrations, thereby ensuring the integrity and stability of the structure in which they are employed.

- Q: Can steel angles be used for foundation supports?

- Yes, steel angles can be used for foundation supports. Steel angles provide structural support and stability, making them suitable for various construction applications, including foundation supports.

- Q: Can steel angles be welded together?

- Yes, steel angles can be welded together. Welding is a common method used to join steel angles, as well as other steel components, in various industries. This process involves melting the base metals to be joined and adding a filler material to create a strong and permanent bond. Welding angles together allows for the creation of structural connections, support frames, and other applications where a strong and durable joint is required. Welding techniques such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, or stick welding can be used depending on the specific requirements of the project. It is important to follow proper welding procedures, including selecting appropriate welding techniques, using the correct welding consumables, and ensuring proper preparation and alignment of the steel angles, to achieve successful and reliable welded joints.

- Q: Can steel angles be used as supports for suspended acoustical ceilings?

- Steel angles have the capacity to function as supports for suspended acoustical ceilings. They are frequently employed as a primary structural element in suspended ceiling systems, serving to establish stability and provide support for the acoustical ceiling tiles. Additionally, they aid in evenly distributing the weight across the ceiling grid. To ensure the secure installation and optimal sound absorption, the steel angles are typically placed at regular intervals along the ceiling's perimeter and connected to the main suspension system. The utilization of steel angles guarantees that the acoustical ceiling remains firmly in position while effectively enhancing the acoustic qualities of the area.

- Q: What are the different types of connections used for steel angles in steel frames?

- There are several types of connections used for steel angles in steel frames, including welded connections, bolted connections, and riveted connections. Welded connections involve fusing the angles together using heat, creating a strong and permanent bond. Bolted connections involve using bolts and nuts to secure the angles together, allowing for easy disassembly if necessary. Riveted connections involve using rivets, which are metal pins, to hold the angles together by forming a permanent, tight fit. The choice of connection type depends on the specific requirements of the steel frame and the desired level of strength and durability.

- Q: Can steel angles be used for manufacturing outdoor benches?

- Yes, steel angles can be used for manufacturing outdoor benches. Steel angles are strong and durable, making them suitable for outdoor use where the bench may be exposed to harsh weather conditions. Additionally, steel angles can be easily welded together to create a sturdy frame for the bench. The steel frame can then be paired with other materials such as wood or metal slats to form the seating surface. Overall, steel angles are a popular choice for manufacturing outdoor benches due to their strength, durability, and versatility.

- Q: Can steel angles be used in the construction of religious institutions?

- Yes, steel angles can be used in the construction of religious institutions. Steel angles are versatile and commonly used in construction due to their strength, durability, and ability to withstand heavy loads. They can be used to provide structural support and stability to the building, ensuring its longevity and safety. Whether it is for columns, beams, trusses, or framing, steel angles can be effectively utilized in the construction of religious institutions to meet the specific design and engineering requirements.

- Q: What is the cost of steel angles compared to other materials?

- The cost of steel angles compared to other materials can vary depending on various factors such as the type and grade of steel, market conditions, and availability. However, in general, steel angles tend to be a cost-effective option when compared to other materials commonly used for structural or construction purposes. Steel angles are widely used in various industries including construction, manufacturing, and infrastructure due to their durability, strength, and versatility. Compared to materials like aluminum or stainless steel, steel angles are often more affordable. This is because steel is a widely available material and can be produced in large quantities, leading to cost efficiencies in manufacturing processes. Additionally, steel angles have a long lifespan and require minimal maintenance, further contributing to their cost-effectiveness over time. They also offer excellent load-bearing capabilities, making them suitable for a wide range of applications, including building frames, support structures, and machinery. However, it is important to note that the cost of steel angles can still vary depending on the specific requirements and specifications of a project. Factors such as size, length, thickness, and any additional treatments or finishes can influence the price. Therefore, it is advisable to consult with suppliers or manufacturers to obtain accurate and up-to-date pricing information based on individual project needs.

- Q: Can steel angles be used for underground or subterranean structures?

- Yes, steel angles can be used for underground or subterranean structures. Steel angles are versatile and commonly used in construction due to their strength, durability, and ability to withstand high levels of stress. In underground or subterranean structures, steel angles can be used for a variety of purposes such as providing structural support, reinforcing concrete walls or floors, or creating framing systems. They can also be used for retaining walls, tunnel linings, underground parking structures, or underground utility tunnels. The corrosion resistance of steel angles can be enhanced through various coatings or treatments, making them suitable for underground environments where moisture, soil, or other corrosive elements may be present. Overall, steel angles are a reliable and effective choice for underground or subterranean structures due to their strength, adaptability, and resistance to various environmental factors.

Send your message to us

S235JR Angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords